Natural granite offers unique patterns and durability forged by geological processes, making each slab one-of-a-kind with inherent resistance to heat and scratches. Engineered stone combines crushed granite or quartz with resins, providing more uniform appearance and enhanced stain resistance, but may lack the authentic feel and thermal properties of natural stone. Choosing between natural granite and engineered stone depends on priorities like aesthetic variation, maintenance, and budget constraints.

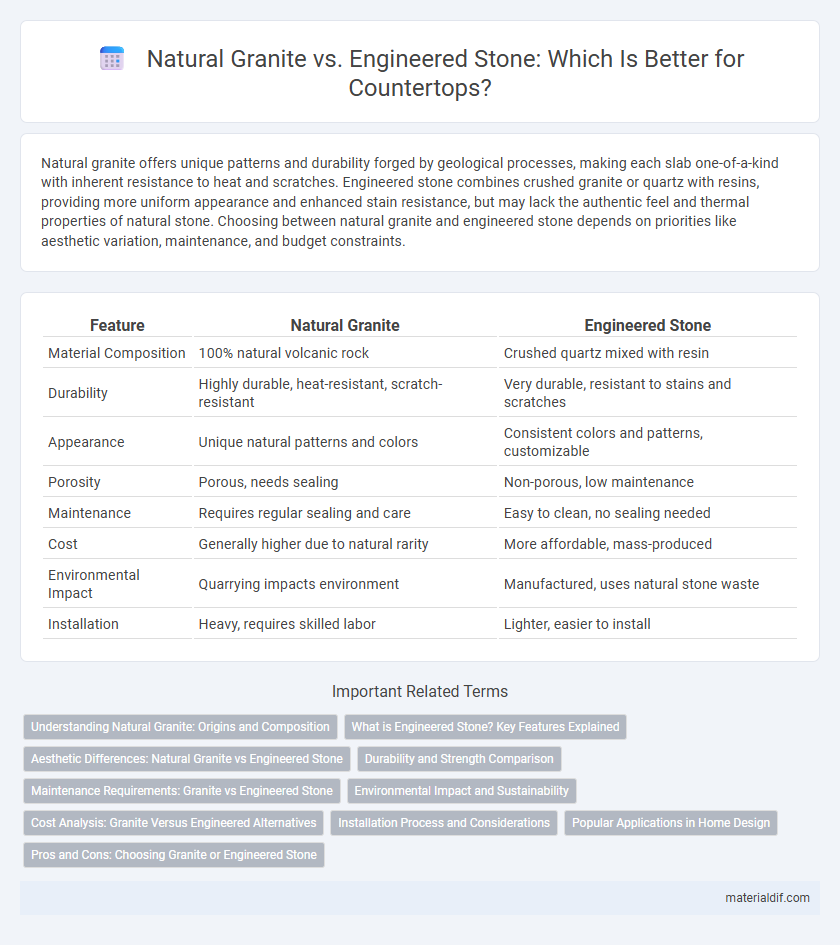

Table of Comparison

| Feature | Natural Granite | Engineered Stone |

|---|---|---|

| Material Composition | 100% natural volcanic rock | Crushed quartz mixed with resin |

| Durability | Highly durable, heat-resistant, scratch-resistant | Very durable, resistant to stains and scratches |

| Appearance | Unique natural patterns and colors | Consistent colors and patterns, customizable |

| Porosity | Porous, needs sealing | Non-porous, low maintenance |

| Maintenance | Requires regular sealing and care | Easy to clean, no sealing needed |

| Cost | Generally higher due to natural rarity | More affordable, mass-produced |

| Environmental Impact | Quarrying impacts environment | Manufactured, uses natural stone waste |

| Installation | Heavy, requires skilled labor | Lighter, easier to install |

Understanding Natural Granite: Origins and Composition

Natural granite is an igneous rock formed from the slow crystallization of magma beneath the Earth's surface, resulting in a coarse-grained texture composed primarily of quartz, feldspar, and mica. Its unique mineral composition and natural formation process contribute to its durability, distinctive patterns, and color variations, which cannot be exactly replicated. Understanding these geological origins helps distinguish natural granite from engineered stone, which is man-made using crushed stone and resins.

What is Engineered Stone? Key Features Explained

Engineered stone is a composite material made from crushed natural quartz mixed with resins and pigments, offering consistent color and pattern unlike natural granite's unique veining. Its non-porous surface provides superior resistance to stains, scratches, and bacteria, making it ideal for kitchen countertops and high-traffic areas. Engineered stone requires less maintenance and can be customized in various colors and finishes, providing a modern alternative to the natural durability and aesthetic of granite.

Aesthetic Differences: Natural Granite vs Engineered Stone

Natural granite features unique, irregular veining and color variations formed by geological processes, offering a one-of-a-kind aesthetic appeal. Engineered stone displays consistent patterns and uniform coloration achieved through resin and pigment blending, providing a more predictable look. The tactile texture of natural granite often contrasts with the smoother, more polished finish of engineered stone surfaces.

Durability and Strength Comparison

Natural granite boasts exceptional durability and strength due to its dense composition of quartz, feldspar, and mica, making it highly resistant to scratches and heat. Engineered stone, composed mainly of crushed natural quartz mixed with resin, offers superior consistency and non-porous surface properties but may be less heat-resistant and prone to chipping under heavy impact. The hardness of natural granite rates about 6-7 on the Mohs scale, while engineered quartz surfaces typically achieve similar hardness, though resin content can affect long-term strength and maintenance requirements.

Maintenance Requirements: Granite vs Engineered Stone

Natural granite requires periodic sealing to prevent stains and damage from moisture, while engineered stone is non-porous and generally maintenance-free, resisting stains and bacteria without sealing. Granite's maintenance involves regular cleaning with pH-neutral products and occasional resealing every 1 to 3 years based on usage. Engineered stone surfaces only need routine wiping with mild soap and water, offering long-term durability with minimal upkeep.

Environmental Impact and Sustainability

Natural granite is a durable, low-maintenance stone that requires minimal processing, resulting in a lower carbon footprint compared to engineered stone, which involves resins and synthetic materials that can emit volatile organic compounds (VOCs) and contribute to microplastic pollution. Quarrying natural granite, however, can lead to habitat disruption and significant energy use, while engineered stone often utilizes recycled materials, potentially reducing waste but increasing chemical usage. Sustainable choices depend on sourcing practices and lifecycle assessments, with natural granite favored for its longevity and minimal chemical treatment, and engineered stone offering opportunities for recycling and resource efficiency.

Cost Analysis: Granite Versus Engineered Alternatives

Natural granite typically costs between $40 to $100 per square foot, reflecting its durability and unique veining, while engineered stone averages $50 to $120 per square foot due to its consistent appearance and lower maintenance needs. Installation expenses for natural granite are often higher because of its weight and required sealing, whereas engineered stone offers easier, more cost-effective installation processes. Evaluating total cost of ownership, engineered stone may present savings in upkeep and longevity despite a higher initial price point.

Installation Process and Considerations

Natural granite requires precise cutting and sealing during installation due to its porous nature and unique veining patterns, which can complicate fitting and finishing. Engineered stone offers more uniformity and easier handling, often allowing faster installation with fewer adjustments. Both materials demand professional expertise, but engineered stone typically minimizes installation time and maintenance considerations.

Popular Applications in Home Design

Natural granite is widely used for kitchen countertops, bathroom vanities, and flooring due to its durability and unique veining patterns that enhance aesthetic appeal. Engineered stone, composed of crushed quartz and resin, offers consistent color and pattern, making it ideal for modern backsplashes, shower walls, and commercial flooring where uniformity is desired. Both materials provide excellent heat and scratch resistance, but natural granite's natural variations make it a favorite for statement pieces in home design.

Pros and Cons: Choosing Granite or Engineered Stone

Natural granite offers superior durability and unique, natural patterns that enhance aesthetic appeal, making it an excellent choice for long-lasting countertops. Engineered stone provides consistent color and pattern, lower porosity, and easier maintenance due to its non-porous surface, but may lack the natural variation and heat resistance of granite. Selecting between granite and engineered stone depends on priorities such as durability, maintenance, budget, and desired visual effect.

Natural Granite vs Engineered Stone Infographic

materialdif.com

materialdif.com