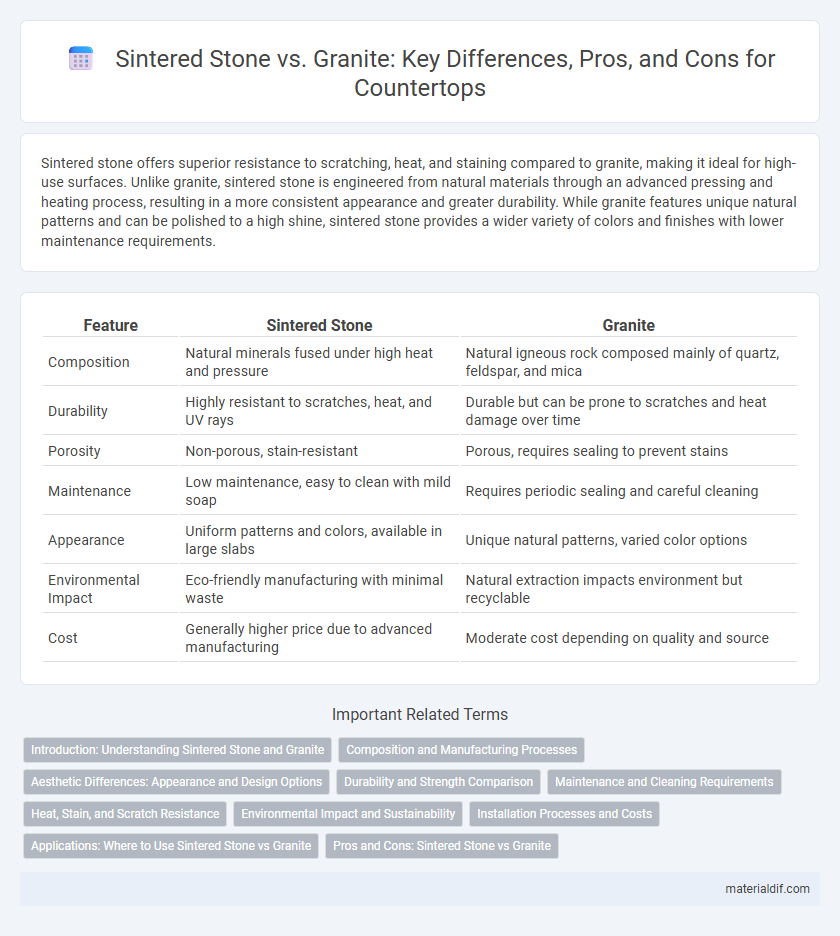

Sintered stone offers superior resistance to scratching, heat, and staining compared to granite, making it ideal for high-use surfaces. Unlike granite, sintered stone is engineered from natural materials through an advanced pressing and heating process, resulting in a more consistent appearance and greater durability. While granite features unique natural patterns and can be polished to a high shine, sintered stone provides a wider variety of colors and finishes with lower maintenance requirements.

Table of Comparison

| Feature | Sintered Stone | Granite |

|---|---|---|

| Composition | Natural minerals fused under high heat and pressure | Natural igneous rock composed mainly of quartz, feldspar, and mica |

| Durability | Highly resistant to scratches, heat, and UV rays | Durable but can be prone to scratches and heat damage over time |

| Porosity | Non-porous, stain-resistant | Porous, requires sealing to prevent stains |

| Maintenance | Low maintenance, easy to clean with mild soap | Requires periodic sealing and careful cleaning |

| Appearance | Uniform patterns and colors, available in large slabs | Unique natural patterns, varied color options |

| Environmental Impact | Eco-friendly manufacturing with minimal waste | Natural extraction impacts environment but recyclable |

| Cost | Generally higher price due to advanced manufacturing | Moderate cost depending on quality and source |

Introduction: Understanding Sintered Stone and Granite

Sintered stone is an engineered surface created by compacting natural minerals under extreme heat and pressure, resulting in a highly durable and non-porous material. Granite is a natural igneous rock composed primarily of quartz and feldspar, known for its strength and unique veining patterns formed over millions of years. Both materials are popular for countertops and flooring, but sintered stone offers enhanced resistance to stains, scratches, and heat compared to traditional granite.

Composition and Manufacturing Processes

Sintered stone consists of a blend of natural minerals such as quartz, feldspar, and kaolin, which undergo a high-pressure, high-temperature process called sintering to form a durable, non-porous surface. Granite is a natural igneous rock composed primarily of quartz, feldspar, and mica, extracted directly from quarries and cut into slabs without extensive processing. The manufacturing process of sintered stone enhances material homogeneity and resistance, while granite retains its natural texture and strength from geological formation.

Aesthetic Differences: Appearance and Design Options

Sintered stone offers a broader range of colors, patterns, and finishes, often mimicking natural materials like marble and wood with high precision, while granite showcases unique, natural veining and granular textures that vary with each slab. The uniformity and slim profiles of sintered stone panels allow for sleek, modern designs, contrasting with granite's more organic, classic aesthetic and thicker, heavier slabs. Both materials provide durable surfaces, but sintered stone excels in consistent visual appeal and versatility in large format applications.

Durability and Strength Comparison

Sintered stone exhibits exceptional durability and resistance to scratches, stains, and heat, often surpassing traditional granite in these aspects due to its engineered composition of natural minerals and advanced manufacturing techniques. Granite, known for its natural strength and toughness, remains highly resistant to impact and chipping but may require periodic sealing to maintain its resilience against moisture and stains. The dense, non-porous surface of sintered stone offers superior strength and longevity, making it an ideal choice for high-traffic areas and demanding applications where maximum durability is essential.

Maintenance and Cleaning Requirements

Sintered stone offers superior stain resistance and requires minimal maintenance compared to granite, which often needs regular sealing to prevent absorption and staining. Cleaning sintered stone involves only mild detergents and water, whereas granite demands pH-balanced cleaners to protect its porous surface. The durability of sintered stone also reduces the risk of scratches and damage, making it a low-maintenance option over time.

Heat, Stain, and Scratch Resistance

Sintered stone offers superior heat resistance, withstanding temperatures up to 1200degC, compared to granite's tolerance of around 600degC, making it ideal for heat-prone surfaces. In terms of stain resistance, sintered stone is non-porous and less prone to absorbing liquids, whereas granite requires sealing to prevent staining from oils, wine, and acids. Scratch resistance is enhanced in sintered stone due to its manufacturing process, resulting in a harder surface than granite, which can scratch more easily under heavy use.

Environmental Impact and Sustainability

Sintered stone offers enhanced sustainability by using natural raw materials like quartz, feldspar, and kaolin, processed with less water and generating lower CO2 emissions compared to granite quarrying. Granite extraction involves significant landscape disruption and energy-intensive mining, leading to habitat loss and higher carbon footprints. Sintered stone's durability and recyclability contribute to reduced environmental impact, making it a greener alternative for eco-conscious construction and design projects.

Installation Processes and Costs

Sintered stone installation involves lightweight slabs that are easier to handle and cut, reducing labor time compared to traditional granite, which requires heavy-duty equipment due to its dense and heavy nature. Granite installation costs are generally higher because of the need for specialized tools and skilled labor to ensure proper sealing and fitting, while sintered stone, being more uniform and less porous, often allows for quicker installation and lower maintenance expenses. Both materials require professional installation, but sintered stone offers cost savings through streamlined processes and reduced installation complexity.

Applications: Where to Use Sintered Stone vs Granite

Sintered stone excels in outdoor applications such as facades, countertops, and flooring due to its high resistance to UV rays, scratches, and heat. Granite is preferred for kitchen countertops, bathroom vanities, and heavy-use surfaces because of its natural durability, heat resistance, and unique texture. Both materials are suitable for interior and exterior use, but sintered stone offers greater versatility in large-format installations and non-porous properties ideal for hygiene-sensitive areas.

Pros and Cons: Sintered Stone vs Granite

Sintered stone offers exceptional durability and resistance to scratches, stains, and heat, making it ideal for high-traffic surfaces, while granite provides natural beauty and unique patterns with strong heat resistance but requires more maintenance due to its porous nature. Sintered stone is non-porous and highly hygienic, reducing the risk of bacteria buildup compared to granite, which needs regular sealing to prevent absorption and staining. Granite's natural variation and earthy tones appeal to those seeking authentic stone aesthetics, whereas sintered stone offers a wider range of colors and consistent patterns through its engineered manufacturing process.

Sintered Stone vs Granite Infographic

materialdif.com

materialdif.com