Gold micron plating offers a thicker and more durable layer of gold compared to flash gold plating, resulting in enhanced resistance to wear and corrosion. Flash gold plating is a very thin coating primarily used for decorative purposes, providing an economical option with limited longevity. Choosing gold micron plating ensures superior quality and longer-lasting shine in pet accessories or jewelry.

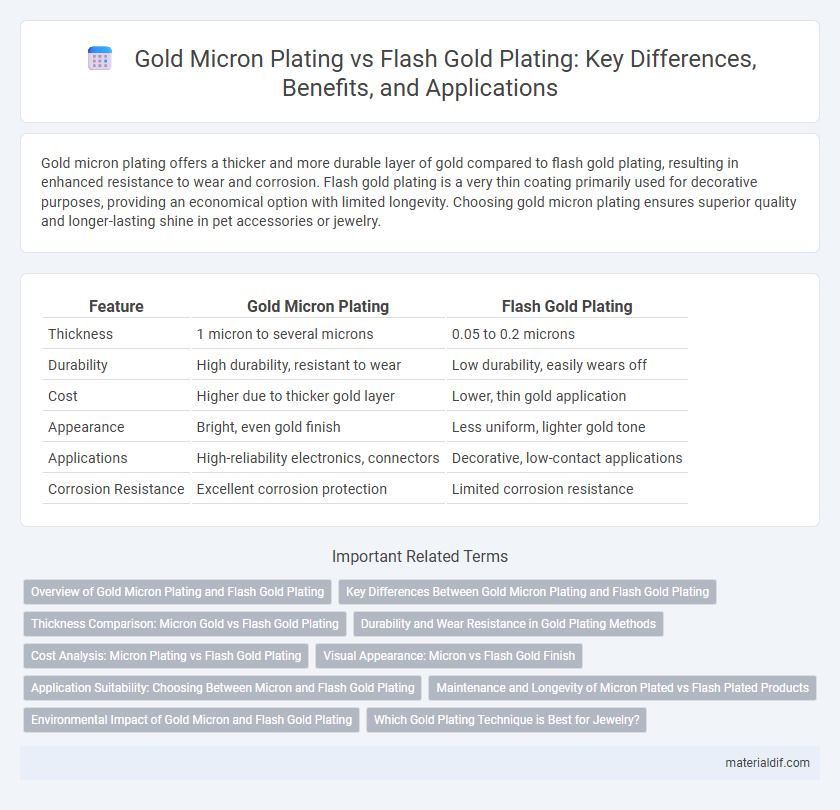

Table of Comparison

| Feature | Gold Micron Plating | Flash Gold Plating |

|---|---|---|

| Thickness | 1 micron to several microns | 0.05 to 0.2 microns |

| Durability | High durability, resistant to wear | Low durability, easily wears off |

| Cost | Higher due to thicker gold layer | Lower, thin gold application |

| Appearance | Bright, even gold finish | Less uniform, lighter gold tone |

| Applications | High-reliability electronics, connectors | Decorative, low-contact applications |

| Corrosion Resistance | Excellent corrosion protection | Limited corrosion resistance |

Overview of Gold Micron Plating and Flash Gold Plating

Gold micron plating involves depositing a precise, thicker layer of gold measured in microns, providing enhanced durability, corrosion resistance, and superior electrical conductivity for high-performance electronic components. Flash gold plating applies an ultra-thin layer of gold, typically measured in microinches, primarily for decorative purposes or as a protective barrier against oxidation in less demanding applications. While gold micron plating ensures long-lasting protection and reliable conductivity, flash gold plating offers a cost-effective solution for short-term use or aesthetic enhancement.

Key Differences Between Gold Micron Plating and Flash Gold Plating

Gold micron plating involves depositing a thicker layer of gold, typically measured in microns, providing enhanced durability and corrosion resistance compared to flash gold plating. Flash gold plating utilizes a very thin gold layer, often less than 0.1 microns, mainly for decorative purposes or brief conductivity enhancement. The key difference lies in thickness and application longevity, with micron plating suited for long-term protection and flash plating for cost-effective surface finish.

Thickness Comparison: Micron Gold vs Flash Gold Plating

Gold micron plating typically ranges from 1 to 5 microns in thickness, offering enhanced durability and corrosion resistance compared to flash gold plating, which is usually only 0.05 to 0.1 microns thick. The substantial difference in thickness makes micron gold plating ideal for applications requiring long-term wear protection, such as high-quality connectors and jewelry. Flash gold plating's ultra-thin layer allows for cost-effective surface finishing but provides minimal protection and is prone to wear and tarnishing over time.

Durability and Wear Resistance in Gold Plating Methods

Gold micron plating offers superior durability and wear resistance compared to flash gold plating due to its thicker layer, typically measuring several microns. This substantial thickness ensures prolonged protection against corrosion and mechanical abrasion, making it ideal for high-contact or high-friction applications. Flash gold plating, being a very thin layer often less than 0.1 microns, provides only minimal wear resistance and is mainly used for decorative purposes or short-term use.

Cost Analysis: Micron Plating vs Flash Gold Plating

Gold micron plating offers a thicker, more durable coating typically ranging from 0.5 to 2 microns, resulting in higher material and processing costs compared to flash gold plating's ultra-thin layer of approximately 0.05 microns. Flash gold plating is cost-effective for applications requiring minimal corrosion resistance and conductivity improvements, while micron plating justifies its premium price through enhanced wear resistance and longer lifespan. Cost analysis reveals that although micron plating demands greater initial investment, it reduces long-term maintenance and replacement expenses in high-performance electronics and connectors.

Visual Appearance: Micron vs Flash Gold Finish

Gold micron plating provides a thicker, more durable layer, resulting in a richer, smoother, and more uniform visual appearance compared to flash gold plating. Flash gold plating offers a very thin coating that may appear brighter initially but tends to show unevenness and dullness over time. The enhanced thickness in micron plating ensures consistent luster and a premium finish ideal for high-quality jewelry and electronics.

Application Suitability: Choosing Between Micron and Flash Gold Plating

Gold micron plating offers a thick, durable layer ideal for high-wear applications such as connectors and aerospace components, ensuring long-term corrosion resistance and electrical conductivity. Flash gold plating provides a very thin, cost-effective coating primarily suited for decorative uses or low-contact electronic components where minimal protection is required. Selecting between micron and flash gold plating depends on the application's mechanical stress, environmental exposure, and budget constraints.

Maintenance and Longevity of Micron Plated vs Flash Plated Products

Gold micron plating offers significantly enhanced durability and longer lifespan compared to flash gold plating, maintaining superior corrosion resistance and wear protection under frequent use. Micron plating typically ranges from 0.75 to 2.5 microns in thickness, resulting in improved maintenance intervals and reduced re-plating frequency, whereas flash plating is much thinner, usually less than 0.1 micron, leading to quicker degradation. This substantial difference in plating thickness directly impacts the longevity and upkeep costs of gold-plated products, making micron plating the preferred choice for high-traffic or high-contact applications.

Environmental Impact of Gold Micron and Flash Gold Plating

Gold micron plating involves depositing a thicker gold layer, typically around 1-5 microns, which requires more gold and energy, leading to a higher environmental footprint compared to flash gold plating. Flash gold plating applies an ultra-thin gold layer, usually less than 0.5 microns, significantly reducing precious metal usage and chemical waste, thus minimizing environmental impact. Both processes use cyanide-based electrolytes, but the shorter plating time in flash gold plating lessens toxic effluent discharge and energy consumption.

Which Gold Plating Technique is Best for Jewelry?

Gold micron plating offers a thicker, more durable layer of gold compared to flash gold plating, making it ideal for high-quality jewelry that requires long-lasting wear and resistance to tarnish. Flash gold plating, while cost-effective and quick, provides only a thin coating that wears off faster, suitable for costume jewelry or pieces not exposed to daily wear. For jewelry demanding superior durability and a luxurious finish, micron plating is the preferred technique.

Gold micron plating vs Flash gold plating Infographic

materialdif.com

materialdif.com