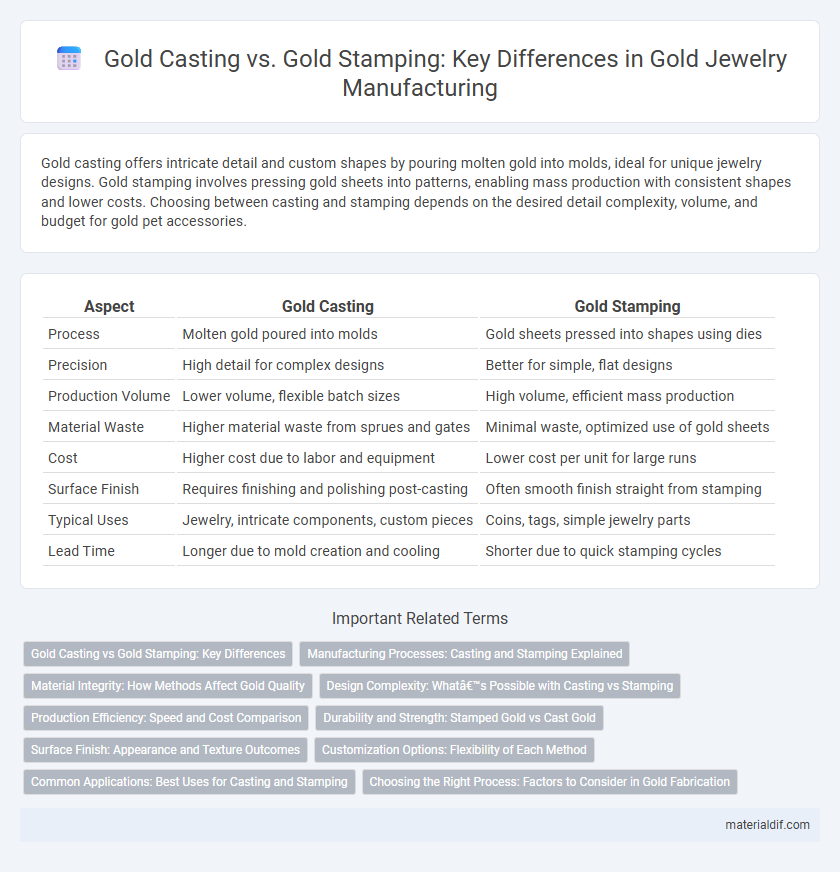

Gold casting offers intricate detail and custom shapes by pouring molten gold into molds, ideal for unique jewelry designs. Gold stamping involves pressing gold sheets into patterns, enabling mass production with consistent shapes and lower costs. Choosing between casting and stamping depends on the desired detail complexity, volume, and budget for gold pet accessories.

Table of Comparison

| Aspect | Gold Casting | Gold Stamping |

|---|---|---|

| Process | Molten gold poured into molds | Gold sheets pressed into shapes using dies |

| Precision | High detail for complex designs | Better for simple, flat designs |

| Production Volume | Lower volume, flexible batch sizes | High volume, efficient mass production |

| Material Waste | Higher material waste from sprues and gates | Minimal waste, optimized use of gold sheets |

| Cost | Higher cost due to labor and equipment | Lower cost per unit for large runs |

| Surface Finish | Requires finishing and polishing post-casting | Often smooth finish straight from stamping |

| Typical Uses | Jewelry, intricate components, custom pieces | Coins, tags, simple jewelry parts |

| Lead Time | Longer due to mold creation and cooling | Shorter due to quick stamping cycles |

Gold Casting vs Gold Stamping: Key Differences

Gold casting involves melting and pouring molten gold into molds, allowing precise and intricate shapes with high detail and thickness control. Gold stamping uses high-pressure dies to press thin gold sheets into desired shapes, offering faster production and cost efficiency but less depth and complexity. Key differences include casting's suitability for complex, high-volume designs and stamping's advantage in speed and uniformity for simpler patterns.

Manufacturing Processes: Casting and Stamping Explained

Gold casting involves melting gold and pouring it into molds for intricate, detailed shapes, ideal for custom jewelry and complex designs. Gold stamping uses high-pressure dies to shape gold sheets, producing precise, repeatable patterns efficiently suited for mass production. Both processes require specialized equipment, with casting excelling in flexibility and stamping in speed and consistency.

Material Integrity: How Methods Affect Gold Quality

Gold casting preserves the intrinsic material integrity by allowing molten gold to flow into detailed molds, minimizing internal stress and reducing the likelihood of surface defects. Gold stamping, while efficient for mass production, can introduce microfractures and deformations due to the high-pressure mechanical forces applied to solid gold sheets. The choice between casting and stamping significantly influences the structural consistency and surface finish of gold jewelry or components.

Design Complexity: What’s Possible with Casting vs Stamping

Gold casting enables intricate and highly detailed designs by allowing molten gold to flow into complex molds, capturing fine textures and three-dimensional shapes impossible to achieve with stamping. Gold stamping, on the other hand, is ideal for producing simple, repetitive patterns and flat surfaces quickly and cost-effectively but lacks the ability to render deep relief and elaborate detailing. Casting supports artistic freedom in jewelry and decorative pieces, while stamping suits mass production of uniform gold components.

Production Efficiency: Speed and Cost Comparison

Gold casting involves melting gold and pouring it into molds, offering flexibility for intricate designs but requiring longer production times and higher labor costs. Gold stamping, by pressing gold sheets into shape using dies, provides faster output and lower material waste, reducing overall manufacturing expenses. For large-scale production demanding speed and cost-effectiveness, gold stamping typically outranks casting in efficiency.

Durability and Strength: Stamped Gold vs Cast Gold

Cast gold offers superior durability and strength due to its solid structure formed by molten metal pouring into molds, resulting in fewer weaknesses and better resistance to wear. Stamped gold, produced by pressing thin sheets of gold into shape, tends to be less durable and more prone to bending or deformation under stress. For applications requiring long-lasting strength and resilience, cast gold is generally the preferred choice over stamped gold.

Surface Finish: Appearance and Texture Outcomes

Gold casting produces a smooth, intricate surface finish with rich texture variations ideal for detailed designs, while gold stamping results in a sharper, more uniform appearance with consistent texture. Casting allows for organic, three-dimensional shapes and subtle surface nuances, enhancing aesthetic depth. In contrast, stamping offers high precision and repeatability, ensuring a polished, flat surface suitable for mass production.

Customization Options: Flexibility of Each Method

Gold casting offers extensive customization options, allowing for intricate designs and complex shapes through precise molten metal pouring into molds. Gold stamping provides faster production but is limited to predefined patterns and shapes due to the press and die constraints. For highly detailed, unique jewelry pieces, casting ensures greater flexibility, while stamping suits simpler, repetitive designs.

Common Applications: Best Uses for Casting and Stamping

Gold casting is commonly used for intricate jewelry designs, detailed sculptures, and custom medallions where precision and complexity are essential. Gold stamping excels in producing high-volume, uniform items like coins, flatware, and decorative plates due to its efficiency and consistency. Both methods serve distinct applications: casting is preferred for artistic and bespoke pieces, while stamping suits mass production of standardized gold products.

Choosing the Right Process: Factors to Consider in Gold Fabrication

Gold casting offers intricate design possibilities and is ideal for complex shapes, while gold stamping provides higher precision and faster production for simpler patterns. Factors such as design complexity, production volume, cost, and finish quality determine the best fabrication method. Selecting the right process ensures optimal durability, aesthetic appeal, and cost-efficiency in gold jewelry manufacturing.

Gold casting vs Gold stamping Infographic

materialdif.com

materialdif.com