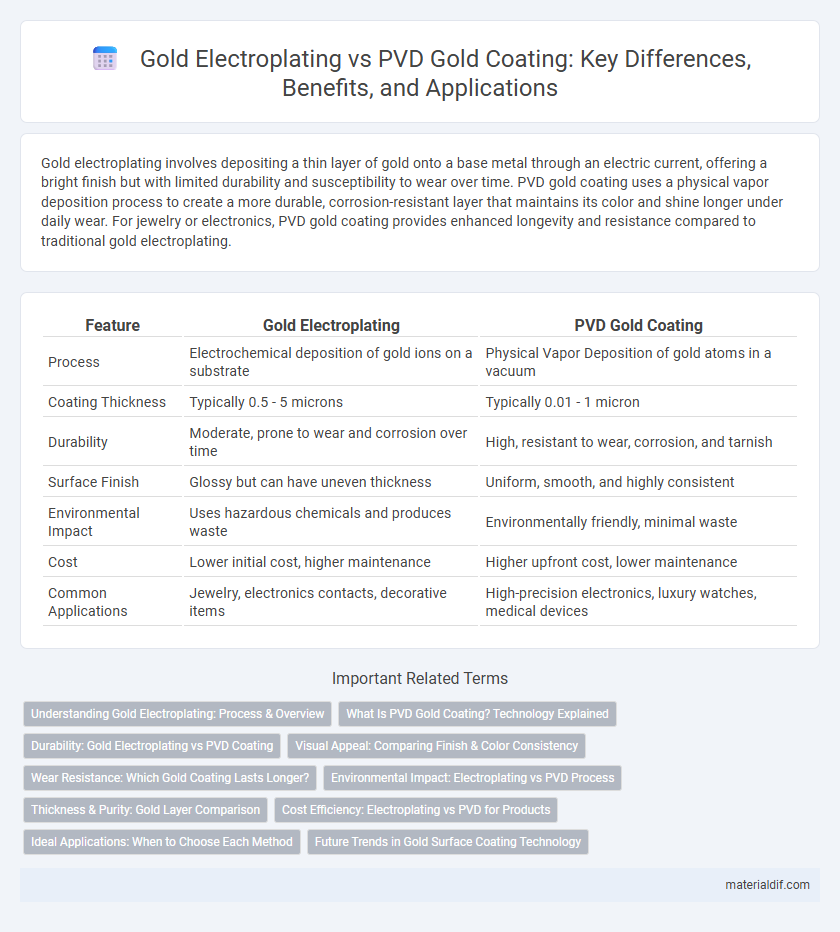

Gold electroplating involves depositing a thin layer of gold onto a base metal through an electric current, offering a bright finish but with limited durability and susceptibility to wear over time. PVD gold coating uses a physical vapor deposition process to create a more durable, corrosion-resistant layer that maintains its color and shine longer under daily wear. For jewelry or electronics, PVD gold coating provides enhanced longevity and resistance compared to traditional gold electroplating.

Table of Comparison

| Feature | Gold Electroplating | PVD Gold Coating |

|---|---|---|

| Process | Electrochemical deposition of gold ions on a substrate | Physical Vapor Deposition of gold atoms in a vacuum |

| Coating Thickness | Typically 0.5 - 5 microns | Typically 0.01 - 1 micron |

| Durability | Moderate, prone to wear and corrosion over time | High, resistant to wear, corrosion, and tarnish |

| Surface Finish | Glossy but can have uneven thickness | Uniform, smooth, and highly consistent |

| Environmental Impact | Uses hazardous chemicals and produces waste | Environmentally friendly, minimal waste |

| Cost | Lower initial cost, higher maintenance | Higher upfront cost, lower maintenance |

| Common Applications | Jewelry, electronics contacts, decorative items | High-precision electronics, luxury watches, medical devices |

Understanding Gold Electroplating: Process & Overview

Gold electroplating involves depositing a thin layer of gold onto a substrate through an electrochemical process that uses an electrolyte solution, ensuring excellent conductivity and corrosion resistance. This method allows precise control over gold thickness, making it ideal for decorative and functional applications in electronics and jewelry. Factors like bath composition, current density, and temperature directly affect coating quality and adhesion during the gold electroplating process.

What Is PVD Gold Coating? Technology Explained

PVD gold coating, or Physical Vapor Deposition, is a vacuum-based process that deposits a thin layer of gold onto a substrate using vaporized gold atoms. This technology offers superior adhesion, durability, and corrosion resistance compared to traditional gold electroplating, making it ideal for high-wear applications. PVD coatings also provide uniform thickness and enhanced environmental sustainability due to the absence of hazardous chemicals used in electroplating.

Durability: Gold Electroplating vs PVD Coating

Gold electroplating provides a relatively thin layer of gold, typically ranging from 0.5 to 2 microns, which can wear off over time due to friction and exposure to chemicals. PVD (Physical Vapor Deposition) gold coating offers a much thicker and more uniform layer, often exceeding 2 microns, resulting in superior hardness and enhanced resistance to scratches and corrosion. For applications demanding long-term durability and wear resistance, PVD gold coating outperforms traditional gold electroplating.

Visual Appeal: Comparing Finish & Color Consistency

Gold electroplating delivers a rich, traditional finish with excellent color depth but may show slight variations and wear over time due to its layered nature. PVD gold coating offers superior color consistency and durability through a vacuum deposition process, resulting in a uniform and long-lasting finish resistant to tarnishing. Both methods enhance visual appeal, but PVD excels in maintaining pristine, vibrant gold tones across large surfaces.

Wear Resistance: Which Gold Coating Lasts Longer?

Gold electroplating offers a thicker, softer layer of gold that can wear off more quickly due to its malleability, making it less durable for high-friction applications. PVD (Physical Vapor Deposition) gold coating produces a much thinner but significantly harder and more wear-resistant layer, resulting in longer-lasting protection against scratches and corrosion. For industrial or decorative uses requiring enhanced durability, PVD gold coatings generally outperform traditional electroplated gold in wear resistance.

Environmental Impact: Electroplating vs PVD Process

Gold electroplating involves the use of hazardous chemicals such as cyanide and heavy metals, generating toxic wastewater that requires careful disposal to prevent environmental contamination. In contrast, PVD (Physical Vapor Deposition) gold coating is a clean, solvent-free process that produces minimal waste and reduces hazardous emissions. The PVD process offers a significantly lower environmental impact compared to traditional electroplating, making it a more sustainable choice for gold finishing.

Thickness & Purity: Gold Layer Comparison

Gold electroplating typically produces a thicker gold layer ranging from 0.5 to 5 microns, offering substantial corrosion resistance and conductivity, while PVD (Physical Vapor Deposition) gold coating results in an ultra-thin layer usually between 0.05 to 0.5 microns that provides superior adhesion and durability. Electroplated gold often achieves higher purity levels close to 24 karats, enhancing its electrical performance, whereas PVD coatings can vary in purity due to deposition parameters but still maintain high-quality finishes with minimal contamination. The choice between electroplating and PVD depends on the required gold thickness and purity for applications like electronics, jewelry, or decorative purposes.

Cost Efficiency: Electroplating vs PVD for Products

Gold electroplating offers a cost-effective solution for large-scale production due to its lower equipment and operational expenses compared to Physical Vapor Deposition (PVD) gold coating. While electroplating uses chemical baths and is ideal for thick, durable layers on complex shapes, PVD provides higher precision and environmental advantages but at a higher initial investment. Manufacturers must weigh the cheaper setup and material costs of electroplating against the superior quality and longevity of PVD when optimizing cost efficiency for gold-coated products.

Ideal Applications: When to Choose Each Method

Gold electroplating is ideal for applications requiring a thick, durable layer, such as jewelry, connectors, and electronic contacts where superior corrosion resistance and conductivity are essential. PVD gold coating suits precision components like watch parts, medical instruments, and decorative items that demand a uniform, wear-resistant finish with minimal environmental impact. Selecting between methods depends on the needed thickness, durability, and environmental considerations of the specific application.

Future Trends in Gold Surface Coating Technology

Future trends in gold surface coating technology emphasize sustainability and enhanced durability, with PVD gold coating gaining prominence due to its environmentally friendly process and superior wear resistance compared to traditional gold electroplating. Innovations in nanotechnology enable thinner, more uniform PVD layers that improve corrosion resistance and aesthetic longevity. The industry increasingly prefers PVD coatings for electronics and jewelry applications, driven by demand for eco-conscious production and high performance under harsh conditions.

Gold Electroplating vs PVD Gold Coating Infographic

materialdif.com

materialdif.com