Electroplated gold involves applying a thin layer of gold onto a base metal using an electric current, offering a cost-effective option but with lower durability and susceptibility to wear over time. PVD gold, or Physical Vapor Deposition, creates a much harder and more durable gold coating by depositing gold atoms in a vacuum environment, ensuring better resistance to scratching and tarnishing. For gold pet accessories, PVD gold provides longer-lasting shine and resilience, making it a superior choice for items exposed to frequent handling.

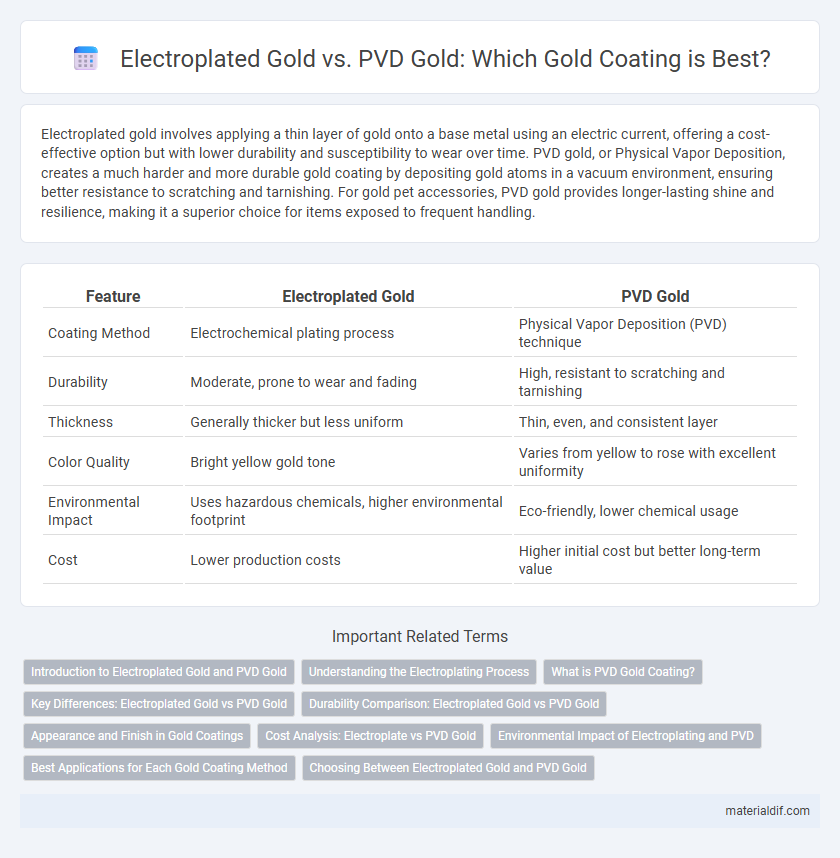

Table of Comparison

| Feature | Electroplated Gold | PVD Gold |

|---|---|---|

| Coating Method | Electrochemical plating process | Physical Vapor Deposition (PVD) technique |

| Durability | Moderate, prone to wear and fading | High, resistant to scratching and tarnishing |

| Thickness | Generally thicker but less uniform | Thin, even, and consistent layer |

| Color Quality | Bright yellow gold tone | Varies from yellow to rose with excellent uniformity |

| Environmental Impact | Uses hazardous chemicals, higher environmental footprint | Eco-friendly, lower chemical usage |

| Cost | Lower production costs | Higher initial cost but better long-term value |

Introduction to Electroplated Gold and PVD Gold

Electroplated gold involves depositing a thin layer of gold onto a base metal using an electric current, resulting in a decorative and cost-effective finish commonly used in jewelry and electronics. PVD (Physical Vapor Deposition) gold is a modern coating method that applies a durable, ultra-thin gold layer through vaporizing gold particles in a vacuum chamber, offering enhanced wear resistance and a uniform surface. Both techniques serve to enhance gold's appearance and longevity, but PVD gold provides superior durability compared to traditional electroplating.

Understanding the Electroplating Process

The electroplating process involves using an electric current to deposit a thin layer of gold onto the surface of a metal object, creating a uniform and durable coating. This technique enhances corrosion resistance and aesthetic appeal, commonly applied to jewelry and electronic components. Unlike PVD gold, electroplated gold relies on a liquid electrolyte solution and electrodeposition, resulting in a thinner layer that may wear off faster under frequent use.

What is PVD Gold Coating?

PVD gold coating, or Physical Vapor Deposition, is a high-tech process that deposits a thin layer of gold onto a surface through vaporization and condensation inside a vacuum chamber, resulting in a durable and corrosion-resistant finish. Unlike traditional electroplated gold, which uses chemical baths to coat metal, PVD creates a stronger bond and higher purity layer that resists tarnishing and wear. This coating method is widely used in jewelry, electronics, and watches for enhanced longevity and aesthetic appeal.

Key Differences: Electroplated Gold vs PVD Gold

Electroplated gold involves depositing a thin layer of gold onto a base metal through an electrochemical process, resulting in a coating that is generally less durable and prone to wear over time. PVD (Physical Vapor Deposition) gold uses a vacuum-based technique to create a highly durable, thin gold film with superior hardness and resistance to tarnishing and corrosion. The key differences lie in durability, coating thickness, and resistance, with PVD gold offering enhanced longevity and a more uniform finish compared to electroplated gold.

Durability Comparison: Electroplated Gold vs PVD Gold

Electroplated gold typically offers a thinner layer that may wear off faster under frequent use, making it less durable compared to PVD gold coatings. PVD (Physical Vapor Deposition) gold creates a thicker, more resilient bond with the base metal, enhancing resistance to scratches, tarnishing, and corrosion. For long-term durability in jewelry, watches, and electronics, PVD gold is generally preferred due to its superior hardness and longevity.

Appearance and Finish in Gold Coatings

Electroplated gold coatings exhibit a warm, rich appearance with a smooth, glossy finish due to the thick, layered deposition of pure gold ions. PVD gold coatings offer a more uniform, precise surface with a slightly matte or satin finish attributed to the atomic-level deposition process, enhancing durability and scratch resistance. Both methods produce visually appealing gold finishes, but electroplating tends to have a deeper luster while PVD provides superior consistency and modern aesthetics.

Cost Analysis: Electroplate vs PVD Gold

Electroplated gold is generally more cost-effective due to lower initial equipment and operating expenses, making it suitable for large-scale, budget-conscious applications. PVD gold offers higher durability and better resistance to wear and corrosion but involves higher upfront investment and maintenance costs, which may increase overall expenditure. Choosing between electroplated and PVD gold depends on balancing cost constraints with desired longevity and performance requirements.

Environmental Impact of Electroplating and PVD

Electroplated gold involves hazardous chemicals like cyanide and produces toxic waste, posing significant environmental risks during disposal and manufacturing. PVD gold coating uses a vacuum-based process that reduces chemical waste and energy consumption, offering a more sustainable and eco-friendly alternative. Choosing PVD gold significantly lowers pollution and health hazards compared to traditional electroplating methods.

Best Applications for Each Gold Coating Method

Electroplated gold provides a thick, durable layer ideal for jewelry, electrical connectors, and decorative items due to its excellent corrosion resistance and conductivity. PVD gold coating excels in high-wear industrial applications like aerospace components and precision tools, offering superior hardness and long-lasting finish with minimal environmental impact. Selecting between electroplated and PVD gold depends on the required durability, appearance, and application environment.

Choosing Between Electroplated Gold and PVD Gold

Electroplated gold offers a thin layer of gold applied via an electrochemical process, providing an affordable and visually appealing finish, but it is prone to wear and tarnish over time. PVD gold utilizes physical vapor deposition to create a durable, corrosion-resistant coating that maintains its luster longer and withstands scratches better. Choosing between electroplated and PVD gold depends on the desired balance of cost, durability, and longevity for jewelry or industrial applications.

Electroplated Gold vs PVD Gold Infographic

materialdif.com

materialdif.com