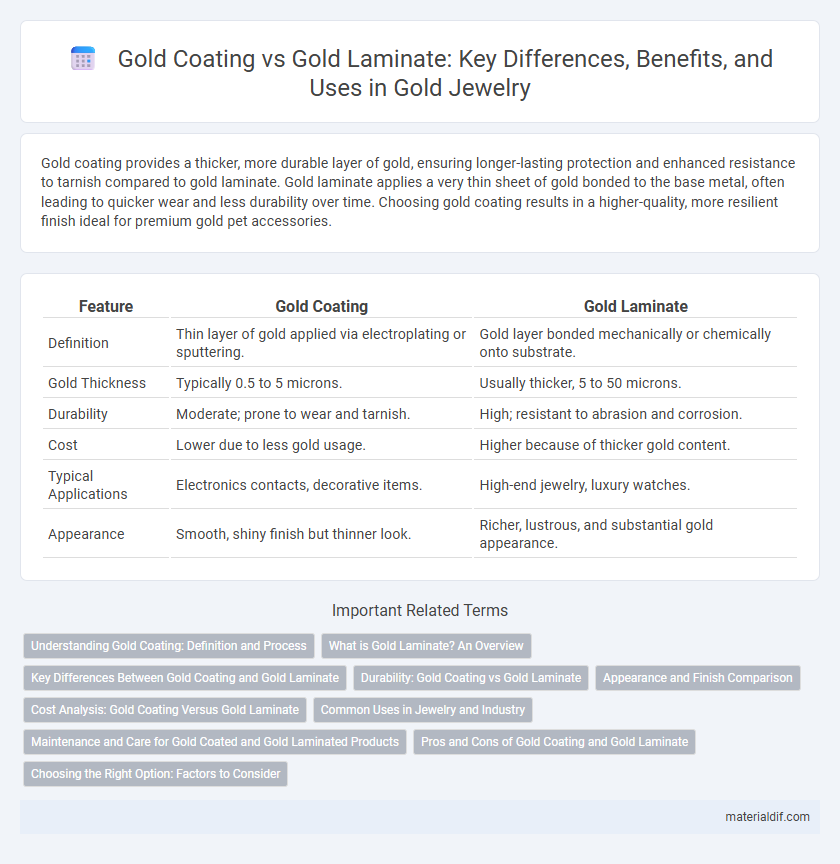

Gold coating provides a thicker, more durable layer of gold, ensuring longer-lasting protection and enhanced resistance to tarnish compared to gold laminate. Gold laminate applies a very thin sheet of gold bonded to the base metal, often leading to quicker wear and less durability over time. Choosing gold coating results in a higher-quality, more resilient finish ideal for premium gold pet accessories.

Table of Comparison

| Feature | Gold Coating | Gold Laminate |

|---|---|---|

| Definition | Thin layer of gold applied via electroplating or sputtering. | Gold layer bonded mechanically or chemically onto substrate. |

| Gold Thickness | Typically 0.5 to 5 microns. | Usually thicker, 5 to 50 microns. |

| Durability | Moderate; prone to wear and tarnish. | High; resistant to abrasion and corrosion. |

| Cost | Lower due to less gold usage. | Higher because of thicker gold content. |

| Typical Applications | Electronics contacts, decorative items. | High-end jewelry, luxury watches. |

| Appearance | Smooth, shiny finish but thinner look. | Richer, lustrous, and substantial gold appearance. |

Understanding Gold Coating: Definition and Process

Gold coating involves depositing a thin layer of pure or near-pure gold onto the surface of another material using techniques such as electroplating or physical vapor deposition (PVD). This process enhances corrosion resistance, electrical conductivity, and aesthetic appeal by creating a uniform and durable gold layer. Gold laminate, in contrast, consists of bonding thin sheets of gold onto substrates, resulting in thicker gold coverage but with different mechanical properties and cost implications.

What is Gold Laminate? An Overview

Gold laminate refers to a material composed of thin layers of gold bonded to a base metal, creating a durable and cost-effective alternative to solid gold. This process involves mechanically bonding multiple layers, often including a core of copper or brass, to provide enhanced strength and wear resistance. Gold lamination is commonly used in jewelry and electronic components where the appearance and conductivity of gold are desired without the higher expense of pure gold.

Key Differences Between Gold Coating and Gold Laminate

Gold coating involves applying a thin layer of pure gold onto a surface using techniques like electroplating, resulting in high conductivity and corrosion resistance but minimal thickness. In contrast, gold laminate consists of a thicker gold layer bonded to a base metal through heat and pressure, offering enhanced durability and longer wear compared to coating. Key differences include the thickness of the gold layer, bonding method, and the resulting mechanical strength and cost-effectiveness for various applications such as electronics and jewelry.

Durability: Gold Coating vs Gold Laminate

Gold coating offers a thinner layer of gold applied through electroplating, making it more susceptible to wear and corrosion over time. Gold laminate consists of a thicker sheet of gold bonded to the base material, providing superior durability and resistance to tarnishing. For applications requiring long-lasting gold appearance and enhanced protection, gold laminate is the preferable choice.

Appearance and Finish Comparison

Gold coating provides a smooth, uniform finish that enhances the surface with a rich, glossy appearance, while gold laminate features a layered structure offering a slightly textured look with varied reflectivity. Coated gold surfaces often exhibit higher durability against tarnishing and maintain their luster longer compared to laminate, which may show wear or peeling over time. The choice between coating and laminate significantly impacts the visual appeal, with coated gold favored for sleek, premium finishes and laminate chosen for decorative applications requiring cost-effective versatility.

Cost Analysis: Gold Coating Versus Gold Laminate

Gold coating typically offers a more affordable option by applying a thin layer of gold over a base metal, reducing material costs while providing the appearance of solid gold. Gold laminate, involving a thicker layer fused under heat and pressure, increases durability but comes with higher production expenses and retail prices. Cost analysis reveals gold coating suits budget-conscious applications, whereas gold laminate justifies its premium through enhanced longevity and wear resistance.

Common Uses in Jewelry and Industry

Gold coating offers a thin layer of pure gold applied through electroplating, commonly used in jewelry for enhancing appearance and preventing tarnish while maintaining affordability. Gold laminate consists of thicker gold sheets bonded to base metals, frequently utilized in both high-end jewelry and electronic components for enhanced durability and conductivity. Industrial applications benefit from gold laminate in connectors and circuit boards due to its superior resistance to corrosion and wear compared to thin gold coatings.

Maintenance and Care for Gold Coated and Gold Laminated Products

Gold-coated products require delicate maintenance with gentle cleaning using non-abrasive cloths to prevent the thin gold layer from wearing off, while gold-laminated items offer slightly better durability but still need protection from harsh chemicals and excessive moisture. Avoid exposure to sweat, perfume, and household cleaners to prolong the lifespan of both gold coatings and laminations. Regularly storing these items in soft pouches or jewelry boxes minimizes scratches and tarnish, ensuring their appearance remains vibrant over time.

Pros and Cons of Gold Coating and Gold Laminate

Gold coating offers superior corrosion resistance and enhances electrical conductivity by applying a thin layer of pure gold directly onto a substrate; however, it is more costly and less durable under mechanical stress compared to alternatives. Gold laminate consists of a thicker gold layer bonded to a base material, providing better wear resistance and longevity but may introduce complexity in manufacturing and increased thickness that affects precision in electronic components. Both methods improve the aesthetic appeal and oxidation resistance of metal surfaces, with gold coating favored for high-performance electronics and gold laminate preferred for applications requiring enhanced durability and cost-efficiency.

Choosing the Right Option: Factors to Consider

When selecting between gold coating and gold laminate, consider factors such as durability, cost, and application purpose. Gold coating provides a thin, affordable layer ideal for decorative uses, while gold laminate offers a thicker, more resilient finish suited for high-wear items. The choice depends on balancing budget constraints with the need for longevity and aesthetic appeal.

Gold Coating vs Gold Laminate Infographic

materialdif.com

materialdif.com