Gold soldering uses a lower melting point filler metal to join gold pieces without melting the base metals, preserving their structure and details. Gold welding involves melting the gold parts directly at the joint, creating a stronger and more seamless bond but requiring precise temperature control to avoid damaging the metal. Choosing between soldering and welding depends on the desired strength, appearance, and complexity of the gold piece.

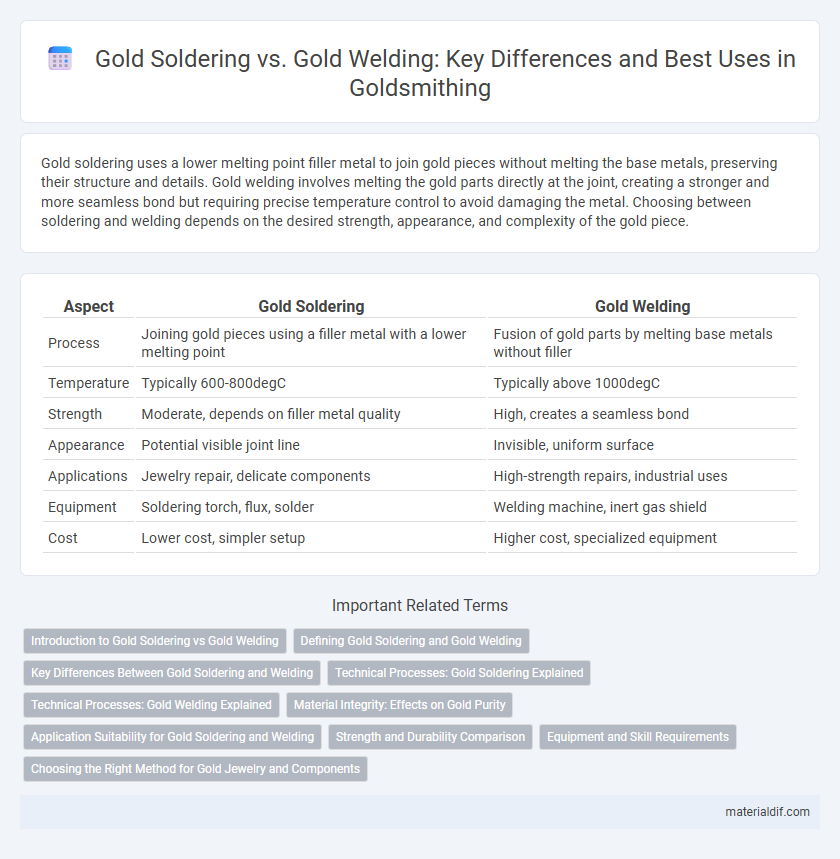

Table of Comparison

| Aspect | Gold Soldering | Gold Welding |

|---|---|---|

| Process | Joining gold pieces using a filler metal with a lower melting point | Fusion of gold parts by melting base metals without filler |

| Temperature | Typically 600-800degC | Typically above 1000degC |

| Strength | Moderate, depends on filler metal quality | High, creates a seamless bond |

| Appearance | Potential visible joint line | Invisible, uniform surface |

| Applications | Jewelry repair, delicate components | High-strength repairs, industrial uses |

| Equipment | Soldering torch, flux, solder | Welding machine, inert gas shield |

| Cost | Lower cost, simpler setup | Higher cost, specialized equipment |

Introduction to Gold Soldering vs Gold Welding

Gold soldering involves joining gold pieces using a filler metal with a lower melting point, ensuring minimal heat exposure and preserving the integrity of delicate components. Gold welding fuses gold parts directly by melting the base metals together, providing a stronger and more seamless bond but requiring higher temperatures and precise control. Understanding the distinctions in technique, temperature, and application is crucial for selecting the appropriate method in jewelry making or electronics fabrication.

Defining Gold Soldering and Gold Welding

Gold soldering involves joining gold pieces using a filler metal with a lower melting point, allowing precise and delicate connections ideal for intricate jewelry work. Gold welding, by contrast, fuses gold components directly at high temperatures without filler metals, creating stronger, more durable bonds often used in industrial applications and repairs. Both techniques require specialized equipment and expertise to maintain the integrity and appearance of gold materials.

Key Differences Between Gold Soldering and Welding

Gold soldering uses a filler metal with a lower melting point than gold to join pieces together without melting the base metals, making it ideal for delicate jewelry work. Gold welding involves melting the actual gold pieces at the joint, creating a stronger, seamless bond that preserves the gold's original properties. The key differences lie in temperature requirements, joint strength, and the extent of base metal melting during the process.

Technical Processes: Gold Soldering Explained

Gold soldering involves joining gold pieces using a filler metal with a lower melting point than gold, creating a strong bond without melting the base metal. The process requires precise temperature control and flux application to prevent oxidation and ensure a clean joint. Soldering is preferred for delicate gold jewelry repairs and intricate designs where thermal distortion must be minimized.

Technical Processes: Gold Welding Explained

Gold welding involves the precise application of high heat to join gold pieces without melting the base metals, creating strong, seamless bonds ideal for intricate jewelry repairs. This technique uses specialized welding machines emitting controlled electric currents to fuse gold at specific points, preserving the integrity of delicate designs. Unlike gold soldering, which relies on melting alloy filler metals, gold welding produces cleaner joints with minimal alteration to the original gold material.

Material Integrity: Effects on Gold Purity

Gold soldering involves melting a filler metal with a lower melting point than gold, which can introduce impurities and slightly alter the gold's original purity. Gold welding melts the gold pieces directly, preserving the material's integrity and maintaining the highest level of gold purity. The choice between soldering and welding significantly impacts the final quality and durability of gold jewelry or components.

Application Suitability for Gold Soldering and Welding

Gold soldering is ideal for delicate jewelry repairs and intricate designs due to its ability to join pieces without melting the base metal, preserving fine details and surface finish. Gold welding suits applications requiring strong, precise joins in thicker components or structural elements, often used in industrial and high-stress environments. Choosing between soldering and welding depends on factors like gold purity, component thickness, and desired joint strength.

Strength and Durability Comparison

Gold soldering creates joints by melting a filler metal with a lower melting point than gold, resulting in strong but slightly less durable connections prone to weaker heat resistance. Gold welding, particularly laser welding, fuses gold pieces directly, producing joints with superior strength and enhanced durability due to seamless metal integration. This makes gold welding the preferred technique for applications demanding maximum joint integrity and longevity.

Equipment and Skill Requirements

Gold soldering requires precision handheld tools like soldering irons or torches with controlled heat output, demanding steady skills in temperature management and fine detail work. Gold welding involves advanced equipment such as laser welders or TIG welders, which require specialized training to handle high-intensity heat sources and create stronger, more seamless joints. Welding skill sets emphasize metal fusion and structural integrity, while soldering prioritizes delicate filler metal application for intricate connections.

Choosing the Right Method for Gold Jewelry and Components

Gold soldering and gold welding serve distinct purposes in jewelry making, with soldering ideal for joining small parts using a lower melting-point alloy, preserving the gold's integrity and fine details. Welding, on the other hand, fuses metals directly through heat or pressure, creating a stronger joint beneficial for larger or load-bearing components. Selecting the right method depends on the jewelry's design complexity, durability requirements, and the specific gold alloy used, ensuring optimal strength and aesthetic quality.

Gold Soldering vs Gold Welding Infographic

materialdif.com

materialdif.com