Cast gold offers intricate designs by pouring molten metal into molds, ideal for detailed and complex jewelry pieces. Wrought gold is shaped by hammering and bending solid gold, providing superior strength and durability for everyday wear. Choosing between cast and wrought gold depends on the desired design intricacy and the need for robustness in the final piece.

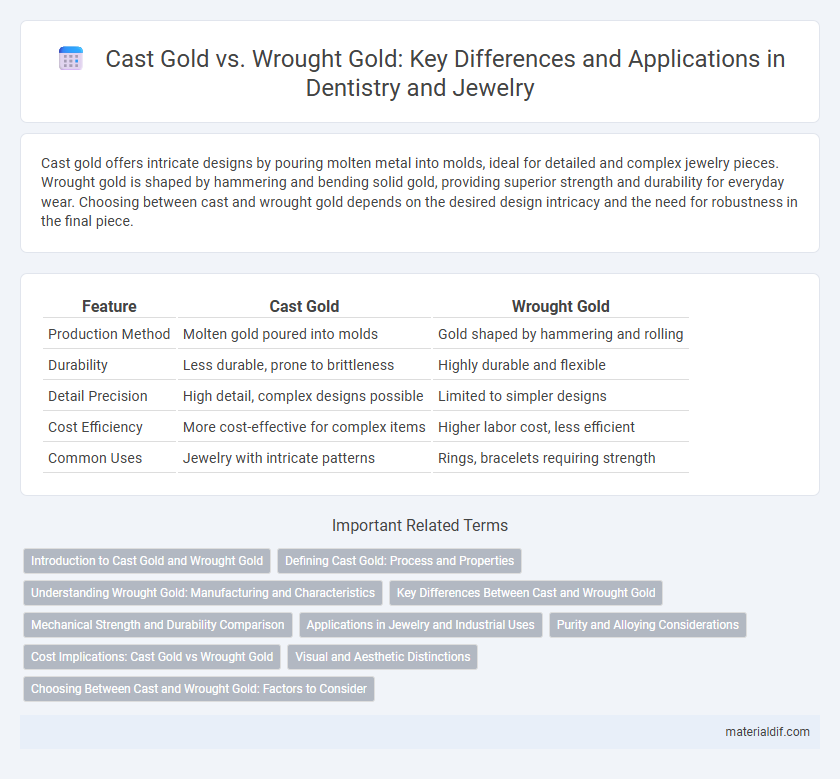

Table of Comparison

| Feature | Cast Gold | Wrought Gold |

|---|---|---|

| Production Method | Molten gold poured into molds | Gold shaped by hammering and rolling |

| Durability | Less durable, prone to brittleness | Highly durable and flexible |

| Detail Precision | High detail, complex designs possible | Limited to simpler designs |

| Cost Efficiency | More cost-effective for complex items | Higher labor cost, less efficient |

| Common Uses | Jewelry with intricate patterns | Rings, bracelets requiring strength |

Introduction to Cast Gold and Wrought Gold

Cast gold is created by melting gold and pouring it into molds, allowing for intricate shapes and detailed designs often used in jewelry and decorative items. Wrought gold involves mechanical working, such as hammering and rolling, resulting in a denser, more durable metal ideal for rings and bands. Both methods influence gold's texture and strength, with cast gold offering artistic freedom and wrought gold providing enhanced structural integrity.

Defining Cast Gold: Process and Properties

Cast gold is created by melting gold and pouring it into molds, allowing for intricate shapes and detailed designs unattainable through other methods. This process produces a dense, uniform structure with excellent strength and durability, often used in high-quality jewelry and intricate decorative items. The microstructure of cast gold typically exhibits a fine grain pattern that enhances its hardness and resistance to wear.

Understanding Wrought Gold: Manufacturing and Characteristics

Wrought gold is produced through mechanical processes such as hammering, rolling, or pressing, which enhance its strength and malleability compared to cast gold. This manufacturing method aligns the gold's grain structure, resulting in improved durability and resistance to cracking under stress. As a result, wrought gold is favored for fine jewelry and high-stress applications due to its superior workability and longevity.

Key Differences Between Cast and Wrought Gold

Cast gold is created by melting gold and pouring it into a mold, resulting in a precise shape but often a more brittle composition due to rapid cooling. Wrought gold is shaped by mechanical processes such as hammering and rolling, enhancing its toughness and flexibility through work hardening. The primary differences lie in durability, with wrought gold offering greater strength and cast gold providing superior detail and intricate designs.

Mechanical Strength and Durability Comparison

Cast gold exhibits higher brittleness due to its solidified structure from molten metal, making it less resistant to impact and mechanical stress. Wrought gold, formed by hammering or rolling, has a refined grain structure that enhances its mechanical strength and flexibility, leading to superior durability in everyday use. The enhanced toughness of wrought gold makes it ideal for jewelry and applications requiring repeated bending or wear.

Applications in Jewelry and Industrial Uses

Cast gold offers intricate designs and fine details, making it ideal for detailed jewelry pieces and ornamental objects, while wrought gold provides superior strength and ductility favored in industrial applications such as electrical connectors and precision instruments. Jewelry crafted from cast gold often features complex patterns and textures, whereas wrought gold's malleability ensures durability and wear resistance in rings, bracelets, and fine chains. Industrial use of wrought gold leverages its excellent conductivity and corrosion resistance, essential for high-performance electronic components and aerospace connectors.

Purity and Alloying Considerations

Cast gold typically contains a higher purity level, often around 18 to 24 karats, allowing for intricate designs due to its fluid casting process, while wrought gold is usually alloyed more heavily to enhance its hardness and durability for shaping and forming. Alloying elements like copper, silver, and zinc are carefully balanced in cast gold to maintain fluidity and prevent porosity, whereas wrought gold alloys prioritize tensile strength and workability through controlled compositions. The purity differences impact not only the mechanical properties but also the alloying strategies used to optimize cast and wrought gold for jewelry manufacturing and industrial applications.

Cost Implications: Cast Gold vs Wrought Gold

Cast gold tends to be more cost-effective due to its lower manufacturing complexity and reduced labor requirements compared to wrought gold. Wrought gold involves extensive mechanical working and shaping processes that increase production time and expenses. The price difference between cast and wrought gold often reflects these variations in craftsmanship and resource investment.

Visual and Aesthetic Distinctions

Cast gold features a smoother surface finish with intricate detailing achieved through mold casting, creating complex and uniform shapes ideal for ornamental designs. Wrought gold displays a more organic texture with visible grain patterns and hammered marks, reflecting skilled handcrafting and artisanal workmanship. The visual distinction lies in cast gold's polished, flawless appearance versus wrought gold's rustic, tactile character.

Choosing Between Cast and Wrought Gold: Factors to Consider

Choosing between cast gold and wrought gold depends on factors like durability, design complexity, and cost. Cast gold offers intricate shapes and detailed designs through mold casting, while wrought gold provides superior strength and malleability due to mechanical working. Consider the intended use, required hardness, and budget when selecting between these two gold processing methods.

Cast Gold vs Wrought Gold Infographic

materialdif.com

materialdif.com