Electroplated gold involves a layer of pure gold deposited onto the surface of a base metal using an electric current, resulting in a durable and shiny finish that enhances jewelry's aesthetic appeal. Chemically bonded gold, also known as gold flash or immersion gold, uses a chemical reaction to bond a thin layer of gold onto the metal, providing a more delicate coating that may wear off faster under frequent use. Choosing electroplated gold offers greater longevity and resistance to tarnish compared to chemically bonded gold, which is ideal for everyday wearable pieces.

Table of Comparison

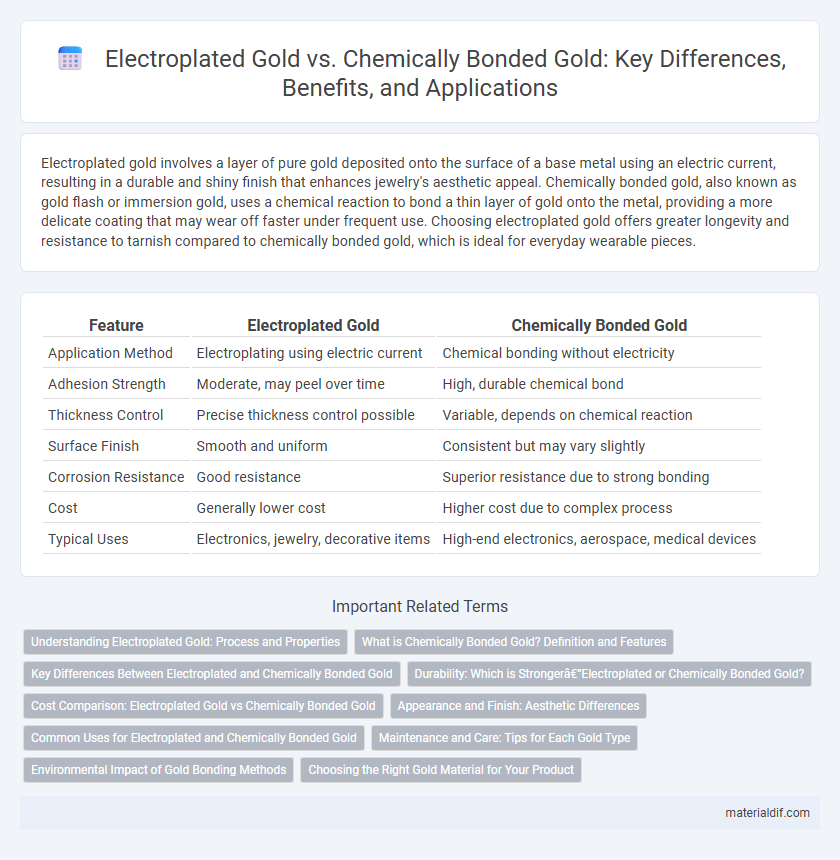

| Feature | Electroplated Gold | Chemically Bonded Gold |

|---|---|---|

| Application Method | Electroplating using electric current | Chemical bonding without electricity |

| Adhesion Strength | Moderate, may peel over time | High, durable chemical bond |

| Thickness Control | Precise thickness control possible | Variable, depends on chemical reaction |

| Surface Finish | Smooth and uniform | Consistent but may vary slightly |

| Corrosion Resistance | Good resistance | Superior resistance due to strong bonding |

| Cost | Generally lower cost | Higher cost due to complex process |

| Typical Uses | Electronics, jewelry, decorative items | High-end electronics, aerospace, medical devices |

Understanding Electroplated Gold: Process and Properties

Electroplated gold involves depositing a thin layer of gold onto a substrate through an electrochemical process, enhancing conductivity and corrosion resistance in electronic components. This method allows precise control over thickness and uniformity, crucial for high-performance applications such as connectors and circuit boards. Electroplated gold typically offers superior adhesion and durability compared to chemically bonded gold, making it a preferred choice in industries requiring reliable, high-quality gold coatings.

What is Chemically Bonded Gold? Definition and Features

Chemically bonded gold refers to a process where gold atoms form a strong molecular bond with the surface of a substrate, creating a durable and conductive layer distinct from surface coatings like electroplated gold. This method ensures enhanced adhesion, resistance to wear, and improved corrosion protection compared to traditional electroplating techniques, often used in electronics and jewelry for long-lasting finishes. The chemical bonding process delivers superior uniformity and thickness control, making it ideal for applications requiring precise electrical conductivity and robust surface protection.

Key Differences Between Electroplated and Chemically Bonded Gold

Electroplated gold involves depositing a thin layer of gold onto a substrate through an electric current, resulting in a uniform but often thinner coating compared to chemically bonded gold, which forms a stronger, more durable molecular bond with the base material. Key differences include the thickness and adhesion strength of the gold layer, with chemically bonded gold offering enhanced resistance to wear and corrosion. Electroplating is generally more cost-effective and widely used in decorative applications, whereas chemically bonded gold is preferred in high-performance electronics and specialty industries requiring superior longevity.

Durability: Which is Stronger—Electroplated or Chemically Bonded Gold?

Electroplated gold features a thin layer of gold applied through an electrical current, making it more prone to wear and fading over time, especially in high-friction applications. Chemically bonded gold, also known as gold flash or immersion gold, creates a stronger molecular bond to the substrate, resulting in superior durability and resistance to scratches and tarnishing. For applications requiring long-lasting gold finish, chemically bonded gold offers enhanced strength compared to electroplated gold.

Cost Comparison: Electroplated Gold vs Chemically Bonded Gold

Electroplated gold typically offers a lower upfront cost due to simpler application processes and reduced material usage, making it ideal for budget-conscious projects and decorative items. Chemically bonded gold, while more expensive initially, provides superior durability and resistance to wear, which can lead to lower maintenance and replacement expenses over time. Cost comparisons should factor in the intended use, longevity requirements, and overall quality expectations to determine the most economically viable option.

Appearance and Finish: Aesthetic Differences

Electroplated gold offers a smooth, glossy surface with a consistent thickness that enhances the jewelry's visual appeal and provides a bright, reflective finish. Chemically bonded gold, or gold flash, presents a thinner, more uniform coating that often results in a subtler, matte-like appearance with fewer imperfections. The choice between electroplating and chemical bonding significantly influences the depth of color, luster, and texture, making electroplated gold ideal for vibrant, polished aesthetics while chemically bonded gold suits minimalist, understated designs.

Common Uses for Electroplated and Chemically Bonded Gold

Electroplated gold is commonly used for decorative purposes, such as jewelry, electronics connectors, and coin finishes due to its cost-effectiveness and ability to provide a uniform gold layer. Chemically bonded gold is preferred in high-precision applications like medical devices, aerospace components, and high-performance electronics where durability and strong adherence are critical. Both techniques enhance corrosion resistance and electrical conductivity but are selected based on the required thickness and application environment.

Maintenance and Care: Tips for Each Gold Type

Electroplated gold requires gentle cleaning with mild soap and water to avoid wearing down the thin gold layer, while chemically bonded gold is more durable and can withstand occasional polishing without risk of damage. Avoid exposing electroplated gold to harsh chemicals or abrasive materials, as the gold layer can easily fade or chip. Chemically bonded gold benefits from regular inspections to ensure the bond remains intact and should be stored separately to prevent scratches.

Environmental Impact of Gold Bonding Methods

Electroplated gold uses an electrical current to deposit gold onto a substrate, often involving toxic chemicals like cyanide, which pose significant environmental hazards through waste discharge and energy consumption. Chemically bonded gold, or electroless plating, employs a autocatalytic chemical reaction without electricity, reducing energy use but still generates hazardous chemical waste requiring careful management. Both methods demand stringent environmental controls, but chemically bonded gold typically has a lower overall carbon footprint due to reduced power consumption.

Choosing the Right Gold Material for Your Product

Electroplated gold offers a thin, cost-effective coating ideal for decorative items and low-wear applications, while chemically bonded gold provides a thicker, more durable layer suitable for high-wear industrial components and electronic contacts. Selecting the right gold material depends on factors such as required durability, electrical conductivity, corrosion resistance, and budget constraints. For products demanding long-term performance and reliability, chemically bonded gold is preferable, whereas electroplated gold suits aesthetic purposes with limited exposure to friction or wear.

Electroplated Gold vs Chemically Bonded Gold Infographic

materialdif.com

materialdif.com