Gold electroplating involves depositing a thin gold layer onto a metal surface through an electrolytic process, providing excellent corrosion resistance and enhanced conductivity. Gold sputtering uses a physical vapor deposition technique to create a uniform and precise gold coating, ideal for delicate or complex electronic components. Compared to electroplating, sputtering offers superior control over film thickness and purity but typically requires more advanced equipment.

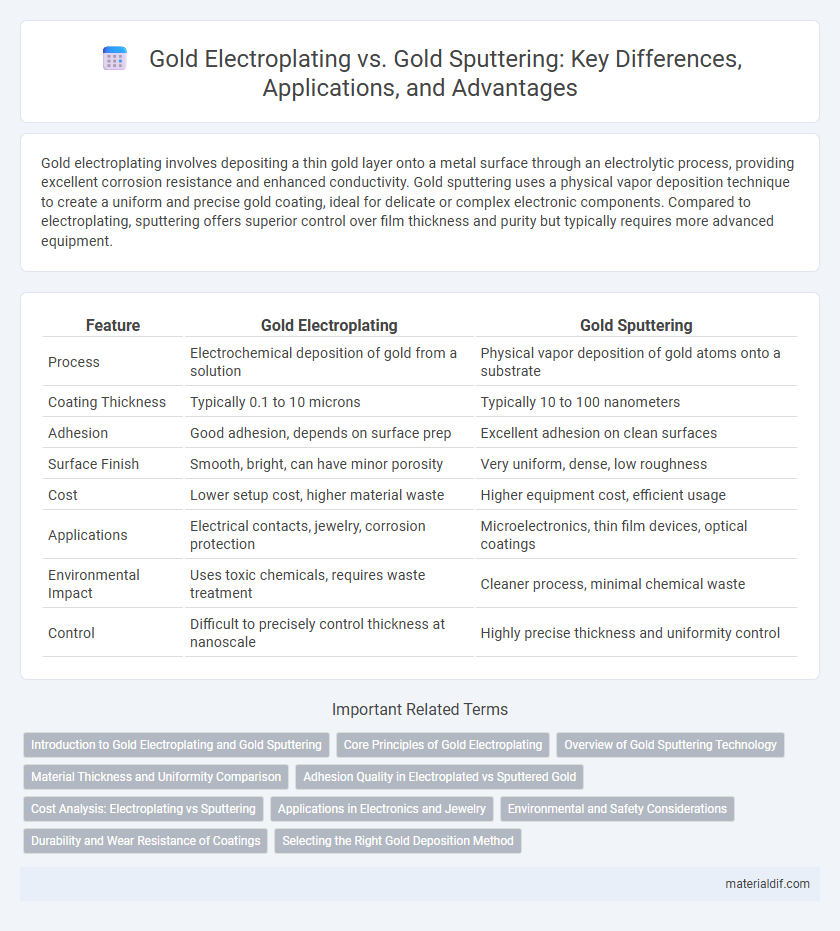

Table of Comparison

| Feature | Gold Electroplating | Gold Sputtering |

|---|---|---|

| Process | Electrochemical deposition of gold from a solution | Physical vapor deposition of gold atoms onto a substrate |

| Coating Thickness | Typically 0.1 to 10 microns | Typically 10 to 100 nanometers |

| Adhesion | Good adhesion, depends on surface prep | Excellent adhesion on clean surfaces |

| Surface Finish | Smooth, bright, can have minor porosity | Very uniform, dense, low roughness |

| Cost | Lower setup cost, higher material waste | Higher equipment cost, efficient usage |

| Applications | Electrical contacts, jewelry, corrosion protection | Microelectronics, thin film devices, optical coatings |

| Environmental Impact | Uses toxic chemicals, requires waste treatment | Cleaner process, minimal chemical waste |

| Control | Difficult to precisely control thickness at nanoscale | Highly precise thickness and uniformity control |

Introduction to Gold Electroplating and Gold Sputtering

Gold electroplating involves depositing a thin layer of gold onto a substrate using an electrolytic solution, enabling precise control over thickness and excellent adhesion. Gold sputtering uses physical vapor deposition by bombarding a gold target with ions, producing a uniform and ultra-thin film ideal for microelectronics and optical applications. Both techniques provide corrosion resistance and enhanced conductivity but differ in process complexity, cost, and thickness control.

Core Principles of Gold Electroplating

Gold electroplating relies on an electrochemical process where a gold salt solution serves as the electrolyte, and an electric current causes gold ions to deposit onto a conductive substrate. The core principle involves oxidation at the anode and reduction at the cathode, facilitating controlled metal ion transfer that produces a uniform, adhesive gold layer. This technique enables precise thickness control and excellent coverage on complex geometries compared to physical vapor deposition methods like gold sputtering.

Overview of Gold Sputtering Technology

Gold sputtering technology involves the physical vapor deposition (PVD) process in which gold atoms are ejected from a solid gold target and deposited onto a substrate, forming a thin, uniform coating. Compared to gold electroplating, sputtering offers superior adhesion, precise thickness control, and enhanced purity, making it ideal for microelectronics and semiconductor applications. The process operates under vacuum conditions, enabling a contamination-free environment that significantly improves coating quality and durability.

Material Thickness and Uniformity Comparison

Gold electroplating typically achieves thicknesses ranging from 0.1 to 5 microns with excellent conformity on complex geometries, while gold sputtering generally produces thinner coatings between 10 to 500 nanometers with superior uniformity on flat surfaces. Electroplated gold layers often exhibit variable thickness due to solution agitation and current distribution, whereas sputtered films maintain highly consistent thickness across the substrate owing to controlled vacuum deposition. For applications demanding precise nanometer-scale uniformity, sputtering is preferred; however, electroplating remains advantageous for thicker, corrosion-resistant gold layers on intricate parts.

Adhesion Quality in Electroplated vs Sputtered Gold

Electroplated gold typically exhibits superior adhesion quality due to its ability to form a thicker, more uniform coating that strongly bonds with the substrate through electrochemical deposition. In contrast, sputtered gold layers are generally thinner, relying on physical vapor deposition, which can result in weaker adhesion and higher susceptibility to delamination under mechanical stress. Studies indicate that electrodeposition creates more robust intermetallic interfaces, enhancing durability in applications requiring reliable gold coatings.

Cost Analysis: Electroplating vs Sputtering

Gold electroplating generally offers a lower initial cost compared to gold sputtering due to simpler equipment and lower material expenses. Sputtering requires high-vacuum systems and precise gas controls, leading to higher operational costs despite producing thinner, more uniform coatings. Evaluating cost-effectiveness depends on factors such as coating thickness, substrate complexity, and production volume, with electroplating preferred for bulk, thicker coatings and sputtering suited for thin, high-precision applications.

Applications in Electronics and Jewelry

Gold electroplating provides a thick, corrosion-resistant coating ideal for electronic connectors and circuit boards, enhancing conductivity and durability in high-reliability applications. Gold sputtering offers ultra-thin, uniform layers suitable for microelectronics and precision semiconductor devices, where controlled thickness and surface smoothness are critical. In jewelry, electroplating creates durable, rich gold finishes on bulk items, while sputtering delivers fine, decorative coatings on delicate or intricate designs requiring minimal material use.

Environmental and Safety Considerations

Gold electroplating involves chemical baths using cyanide-based solutions, which pose significant environmental hazards and require stringent waste treatment protocols to prevent soil and water contamination. Gold sputtering, a physical vapor deposition process, minimizes chemical waste and reduces exposure to toxic substances, offering a safer alternative in controlled industrial environments. Proper ventilation and handling procedures are essential in both methods to protect workers from hazardous fumes and particulate matter.

Durability and Wear Resistance of Coatings

Gold electroplating produces a thicker, more uniform coating that offers superior durability and wear resistance compared to gold sputtering. Sputtered gold layers tend to be thinner and more prone to abrasion, making them less suitable for high-wear applications. Electroplated gold maintains corrosion resistance and conductivity under mechanical stress, extending the lifespan of coated components in demanding environments.

Selecting the Right Gold Deposition Method

Selecting the right gold deposition method depends on the application requirements, such as thickness, adhesion, and surface finish. Gold electroplating offers excellent thickness control and strong adhesion for electronics and jewelry but may involve chemical waste management. Gold sputtering provides uniform thin films with superior surface smoothness, ideal for semiconductor devices and optical coatings, despite higher equipment costs.

Gold electroplating vs Gold sputtering Infographic

materialdif.com

materialdif.com