Gold-coated jewelry features a thin layer of gold applied to a base metal, offering an affordable option with limited durability and susceptibility to wear over time. Gold-clad items have a much thicker layer of gold bonded mechanically to a base metal, providing longer-lasting appearance and greater resistance to tarnish. Choosing between gold-coated and gold-clad depends on budget, desired longevity, and frequency of use.

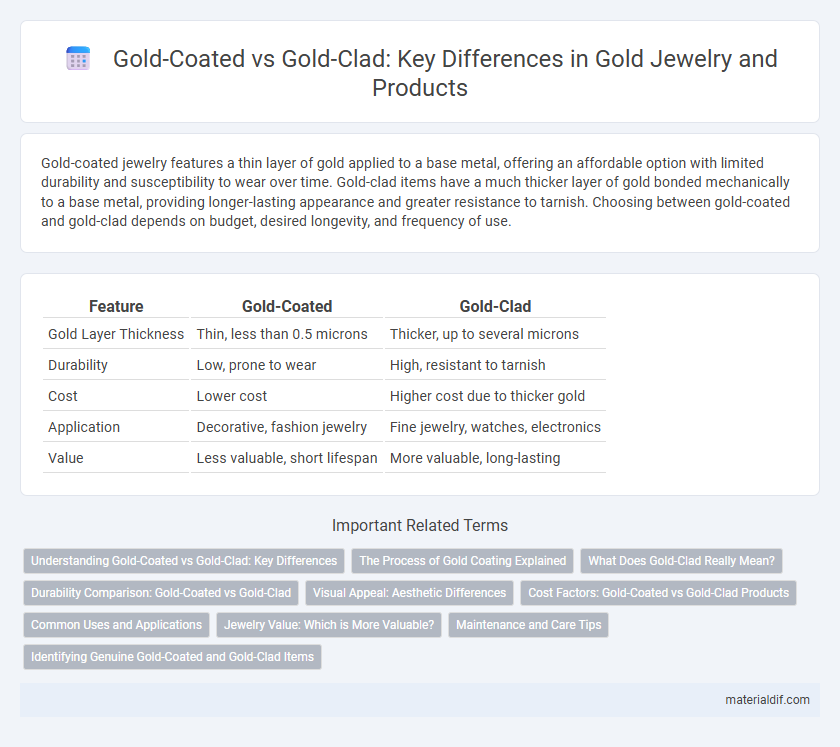

Table of Comparison

| Feature | Gold-Coated | Gold-Clad |

|---|---|---|

| Gold Layer Thickness | Thin, less than 0.5 microns | Thicker, up to several microns |

| Durability | Low, prone to wear | High, resistant to tarnish |

| Cost | Lower cost | Higher cost due to thicker gold |

| Application | Decorative, fashion jewelry | Fine jewelry, watches, electronics |

| Value | Less valuable, short lifespan | More valuable, long-lasting |

Understanding Gold-Coated vs Gold-Clad: Key Differences

Gold-coated items feature a thin layer of pure gold applied through electroplating, resulting in a delicate finish with minimal gold content. Gold-clad products consist of a thicker gold layer mechanically bonded to a base metal, offering greater durability and higher gold value. The primary difference lies in the thickness and longevity of the gold layer, affecting both cost and quality.

The Process of Gold Coating Explained

Gold-coated items undergo a precise electroplating process where a thin layer of pure gold is deposited onto a base metal through an electric current in a gold-containing solution. This method allows for a uniform, microscopically thin gold layer, often just a few microns thick, providing enhanced corrosion resistance and aesthetic appeal. In contrast, gold-clad products involve mechanically bonding a much thicker gold layer to the base metal, resulting in a more durable but heavier gold surface.

What Does Gold-Clad Really Mean?

Gold-clad refers to a base metal coated with a thicker layer of gold compared to gold-plated items, often achieved through mechanical bonding or heat treatment, ensuring greater durability and resistance to wear. The gold layer in gold-clad jewelry typically measures at least 10 karats and accounts for about 5% of the total weight, distinguishing it from thinner gold-plated finishes. This method is ideal for those seeking the appearance of gold with improved longevity without the high cost of solid gold.

Durability Comparison: Gold-Coated vs Gold-Clad

Gold-clad items feature a significantly thicker layer of gold, usually measured in microns, offering enhanced durability and resistance to wear compared to gold-coated pieces, which have a much thinner gold layer often applied through electroplating. The substantial gold layer in gold-clad products prevents tarnishing and maintains aesthetic appeal for longer periods, making them ideal for frequently worn jewelry or high-use items. Gold-coated items may fade or chip more quickly due to their minimal gold content, requiring more careful handling to preserve their appearance.

Visual Appeal: Aesthetic Differences

Gold-coated items feature a thin, uniform layer of gold providing a consistent, bright yellow sheen that enhances visual appeal with a refined, polished finish. Gold-clad pieces have a thicker gold layer bonded to a base metal, offering deeper color saturation and greater durability, resulting in a more robust, luxurious appearance. The visual distinction lies in gold-coated items appearing more delicate and gleaming, while gold-clad goods present a richer, more textured aesthetic that withstands wear better over time.

Cost Factors: Gold-Coated vs Gold-Clad Products

Gold-coated products use a thin layer of gold, significantly reducing material costs compared to gold-clad items, which have a thicker gold layer bonded to a base metal. The process of applying gold plating in gold-coated products is quicker and less expensive, whereas gold-clad manufacturing involves more gold content and complex bonding techniques, increasing overall costs. As a result, gold-clad items tend to have higher durability and resale value but come with a premium price relative to gold-coated alternatives.

Common Uses and Applications

Gold-coated items are often used in electronics and jewelry where a thin layer of gold provides corrosion resistance and electrical conductivity without significant cost. Gold-clad materials feature a thicker gold layer, commonly applied in decorative objects, high-quality jewelry, and musical instruments to ensure durability and enhanced aesthetic appeal. Both finishes leverage gold's conductivity and corrosion-resistant properties but differ in thickness, affecting their longevity and typical applications.

Jewelry Value: Which is More Valuable?

Gold-coated jewelry features a thin layer of gold applied over a base metal, resulting in lower durability and value due to the minimal gold content. Gold-clad jewelry involves a thicker, mechanically bonded layer of gold, offering greater longevity and higher intrinsic value. Collectors and buyers generally consider gold-clad pieces more valuable because of their substantial gold content and better resistance to wear.

Maintenance and Care Tips

Gold-coated jewelry requires gentle cleaning with mild soap and a soft cloth to maintain its thin gold layer, avoiding abrasive materials that can wear it off quickly. Gold-clad pieces, featuring a thicker gold layer bonded to the base metal, allow for more durable use but still benefit from regular polishing and avoiding exposure to chemicals or excessive moisture. Both types should be stored separately in a dry place to prevent scratches and tarnishing, extending the lifespan of their gold finish.

Identifying Genuine Gold-Coated and Gold-Clad Items

Gold-coated items feature a thin layer of pure gold applied using electroplating, often less than 0.5 microns thick, whereas gold-clad items have a much thicker gold layer, typically over 10 microns, fused mechanically to a base metal. Identifying genuine gold-coated or gold-clad pieces involves checking for hallmark stamps indicating karat purity and layer thickness, performing acid tests for authenticity, and assessing wear patterns that reveal the base metal beneath thinning gold layers. Certified testing methods like X-ray fluorescence (XRF) analysis provide precise compositional data, essential for distinguishing authentic gold coatings from imitations.

Gold-coated vs Gold-clad Infographic

materialdif.com

materialdif.com