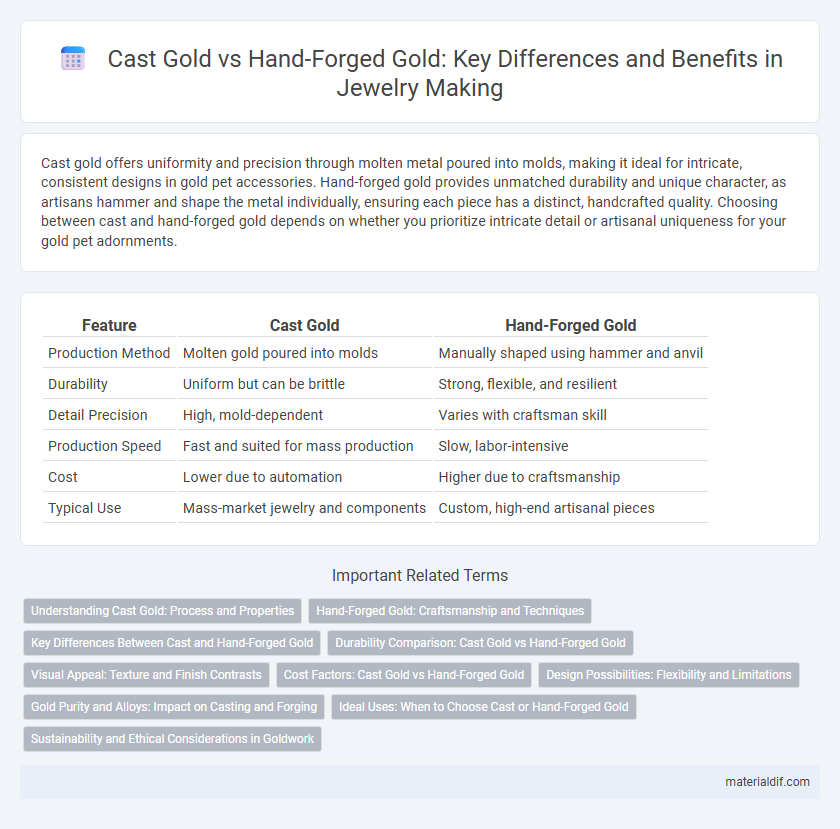

Cast gold offers uniformity and precision through molten metal poured into molds, making it ideal for intricate, consistent designs in gold pet accessories. Hand-forged gold provides unmatched durability and unique character, as artisans hammer and shape the metal individually, ensuring each piece has a distinct, handcrafted quality. Choosing between cast and hand-forged gold depends on whether you prioritize intricate detail or artisanal uniqueness for your gold pet adornments.

Table of Comparison

| Feature | Cast Gold | Hand-Forged Gold |

|---|---|---|

| Production Method | Molten gold poured into molds | Manually shaped using hammer and anvil |

| Durability | Uniform but can be brittle | Strong, flexible, and resilient |

| Detail Precision | High, mold-dependent | Varies with craftsman skill |

| Production Speed | Fast and suited for mass production | Slow, labor-intensive |

| Cost | Lower due to automation | Higher due to craftsmanship |

| Typical Use | Mass-market jewelry and components | Custom, high-end artisanal pieces |

Understanding Cast Gold: Process and Properties

Cast gold is created by melting gold and pouring it into molds, enabling precise shapes and intricate designs with consistent density and smooth surfaces. This process allows for mass production of detailed and uniform pieces, often used in jewelry and decorative items. Cast gold typically exhibits a more homogenous structure compared to hand-forged gold, which affects its strength and malleability.

Hand-Forged Gold: Craftsmanship and Techniques

Hand-forged gold showcases exceptional craftsmanship through meticulous hammering and shaping by skilled artisans, resulting in unique textures and enhanced durability. This traditional technique allows precise control over the gold's malleability, creating intricate designs unattainable by casting methods. The hand-forged process preserves the metal's structural integrity, making each piece a distinctive work of art with superior strength and character.

Key Differences Between Cast and Hand-Forged Gold

Cast gold is produced by melting gold and pouring it into molds, allowing for intricate and consistent designs with high precision and less manual labor. Hand-forged gold involves heating and shaping the metal manually with tools, resulting in unique textures and slight variations that highlight craftsmanship and artisanal value. Key differences include manufacturing speed, design uniformity, and the tactile, one-of-a-kind quality found in hand-forged pieces versus the exact replication possible with cast gold.

Durability Comparison: Cast Gold vs Hand-Forged Gold

Cast gold exhibits uniform hardness and consistent structural integrity, resulting from its molten pouring process into molds, which minimizes internal defects. Hand-forged gold undergoes repeated hammering and shaping at high temperatures, enhancing its density and grain structure, thus increasing resilience and resistance to impact. While cast gold offers precision and ease of reproduction, hand-forged gold typically delivers superior durability and longevity due to its enhanced crystallographic alignment.

Visual Appeal: Texture and Finish Contrasts

Cast gold features a smooth, uniform texture with a polished finish that highlights intricate details and sharp designs, ideal for precise and consistent jewelry. Hand-forged gold offers a unique, organic texture with subtle hammer marks, creating a rustic and artisanal aesthetic that varies with each piece. The contrast between cast gold's sleek surface and hand-forged gold's tactile irregularities affects visual appeal, catering to different stylistic preferences.

Cost Factors: Cast Gold vs Hand-Forged Gold

Cast gold typically costs less due to the lower labor intensity and faster production process, whereas hand-forged gold demands higher expenses because of skilled craftsmanship and time-consuming techniques. Material waste and energy consumption are generally higher in casting, but hand forging requires precision tools and meticulous effort, which increase overall labor costs. Choosing between cast and hand-forged gold often hinges on budget limitations and the desired level of detail and durability in the final piece.

Design Possibilities: Flexibility and Limitations

Cast gold offers extensive design possibilities due to its ability to produce intricate and consistent shapes with fine details, making it ideal for complex and repetitive patterns often seen in jewelry and decorative items. Hand-forged gold provides unique flexibility, allowing artisans to create custom, one-of-a-kind pieces with subtle textures and variations that reflect skilled craftsmanship, though it is limited by the manual labor intensity and precision achievable. The choice between cast and hand-forged gold depends on the desired balance between detailed uniformity and bespoke artistic expression.

Gold Purity and Alloys: Impact on Casting and Forging

Cast gold typically incorporates a higher percentage of alloys such as copper, silver, or zinc to enhance fluidity during the casting process, which can slightly reduce the overall gold purity but improves mold filling and detail retention. Hand-forged gold maintains a closer to pure 24-karat composition or uses carefully measured alloys to enhance malleability and strength without compromising the metal's intrinsic value, resulting in denser, more durable finished products. The difference in alloy composition directly affects the metal's melting point and workability, influencing the choice between casting for intricate designs and forging for structural integrity.

Ideal Uses: When to Choose Cast or Hand-Forged Gold

Cast gold is ideal for intricate designs and mass production due to its ability to capture fine details and repeat uniform shapes efficiently. Hand-forged gold suits custom, artisanal jewelry where durability and unique craftsmanship are paramount, offering superior strength from the hammering process. Opt for cast gold in complex, delicate pieces like filigree or settings, while hand-forged gold excels in robust items such as wedding bands and heirloom-quality rings.

Sustainability and Ethical Considerations in Goldwork

Cast gold involves melting and pouring gold into molds, resulting in efficient material use and minimal waste, which supports sustainable practices within the jewelry industry. Hand-forged gold emphasizes traditional craftsmanship with lower energy consumption, reducing environmental impact and promoting ethical labor practices. Choosing between cast and hand-forged gold depends on balancing sustainability goals with the value placed on artisanal skill and ethical sourcing.

Cast Gold vs Hand-Forged Gold Infographic

materialdif.com

materialdif.com