Gold mesh offers greater flexibility and breathability compared to a gold sheet, making it ideal for applications requiring lightweight and breathable materials. Gold sheets provide a solid, smooth surface that is perfect for decorative purposes or projects needing durability and a polished finish. Choosing between gold mesh and gold sheet depends on the balance between ventilation, flexibility, and structural integrity required for the specific use.

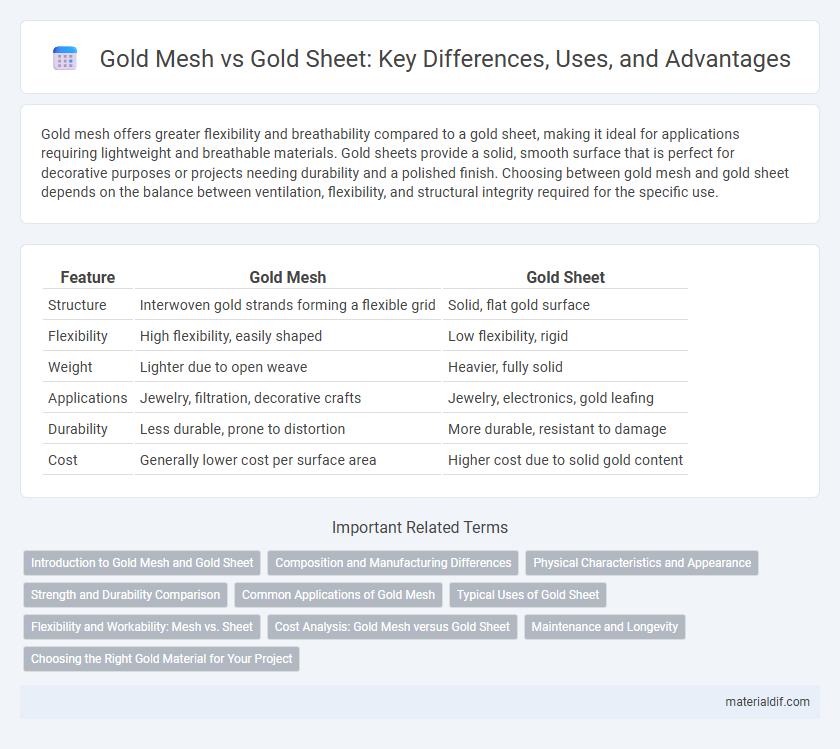

Table of Comparison

| Feature | Gold Mesh | Gold Sheet |

|---|---|---|

| Structure | Interwoven gold strands forming a flexible grid | Solid, flat gold surface |

| Flexibility | High flexibility, easily shaped | Low flexibility, rigid |

| Weight | Lighter due to open weave | Heavier, fully solid |

| Applications | Jewelry, filtration, decorative crafts | Jewelry, electronics, gold leafing |

| Durability | Less durable, prone to distortion | More durable, resistant to damage |

| Cost | Generally lower cost per surface area | Higher cost due to solid gold content |

Introduction to Gold Mesh and Gold Sheet

Gold mesh consists of fine, interwoven gold wires creating a flexible, lightweight structure ideal for applications requiring both strength and malleability, such as filtration or decorative arts. Gold sheets are solid, flat pieces of gold varying in thickness, prized for their smooth surface and uniformity in jewelry making, electronics, and gilding. Both forms leverage gold's exceptional conductivity, corrosion resistance, and lustrous appearance, but serve distinct practical and aesthetic purposes across different industries.

Composition and Manufacturing Differences

Gold mesh consists of interwoven gold wires creating a flexible and porous structure, while gold sheets are solid, flat surfaces formed by rolling or hammering gold into thin layers. The composition in both cases is typically high-purity gold or gold alloys, but manufacturing processes differ: gold mesh involves weaving or knitting fine gold strands, whereas gold sheets are produced through mechanical rolling or pressing techniques. These differences impact the material's applications, with mesh favored for decorative, conductive, or filtration uses and sheets preferred for jewelry, electronics, or gilding.

Physical Characteristics and Appearance

Gold mesh features an intricate network of fine gold wires, offering flexibility and a lightweight structure ideal for delicate designs, while gold sheet provides a solid, smooth surface with uniform thickness, delivering durability and a polished, reflective appearance. The mesh's open pattern enhances breathability and adds texture, contrasted by the gold sheet's continuous, glossy finish that emphasizes richness and luxury. Both forms share the inherent luster and corrosion resistance of gold but differ significantly in tactile feel and visual complexity.

Strength and Durability Comparison

Gold mesh exhibits enhanced flexibility and tensile strength compared to gold sheets, owing to its woven structure that distributes stress more evenly under tension. Gold sheets, while offering a smooth and uniform surface, tend to be more prone to bending and denting due to their solid, continuous form. In applications demanding resilience against deformation, gold mesh provides superior durability by absorbing impacts without compromising structural integrity.

Common Applications of Gold Mesh

Gold mesh is commonly used in biomedical implants and electronics due to its flexibility and high conductivity, making it ideal for wearable sensors and flexible circuits. In contrast, gold sheets are preferred in jewelry and decorative arts for their smooth, malleable surface and reflective quality. The porous structure of gold mesh facilitates tissue integration and improved electrical performance in medical devices, distinguishing it from the solid form of gold sheets.

Typical Uses of Gold Sheet

Gold sheets are commonly used in electronics for flexible circuits, decorative applications, and precision coatings due to their uniform thickness and excellent malleability. Typical uses include gold leaf for gilding artwork and architectural elements, as well as thin foils in medical devices for their biocompatibility and conductivity. Gold sheets also serve in aerospace components where corrosion resistance and reliability are critical.

Flexibility and Workability: Mesh vs. Sheet

Gold mesh offers superior flexibility compared to gold sheets due to its open structure, allowing it to bend and conform easily to complex shapes without cracking. Gold sheets, while providing a smooth and uniform surface, are less flexible and prone to deformation or creasing under stress. The workability of gold mesh excels in applications requiring intricate wrapping or layering, whereas gold sheets are preferred for flat, precise surfaces and straightforward fabrication.

Cost Analysis: Gold Mesh versus Gold Sheet

Gold mesh generally offers cost advantages over gold sheets due to its reduced material thickness and lighter weight, which minimize gold consumption without compromising strength. Manufacturing gold mesh involves intricate weaving processes that can slightly increase labor costs but often remain lower than the expense of sourcing and fabricating solid gold sheets. Price fluctuations in the gold market impact both forms, but the economic efficiency of mesh structures often results in more favorable overall economics for applications requiring flexibility and surface area coverage.

Maintenance and Longevity

Gold mesh offers superior flexibility and breathability, which reduces wear and tear, leading to easier maintenance and longer lifespan compared to rigid gold sheets. Gold sheets, while durable, are more prone to scratches and dents, requiring regular polishing to maintain their shine and integrity. Proper care of gold mesh involves gentle cleaning to preserve its intricate structure, ensuring sustained durability over time.

Choosing the Right Gold Material for Your Project

Gold mesh offers flexibility and breathability, making it ideal for intricate designs and wearable technology, while gold sheets provide a solid, smooth surface perfect for engraving and structural applications. Selecting the right gold material depends on project requirements such as durability, malleability, and aesthetic preferences, with gold mesh excelling in lightweight, decorative uses and gold sheets favored for strength and uniform coverage. Consider factors like thickness, karat purity, and finish to optimize performance and visual appeal in your gold-based project.

Gold mesh vs Gold sheet Infographic

materialdif.com

materialdif.com