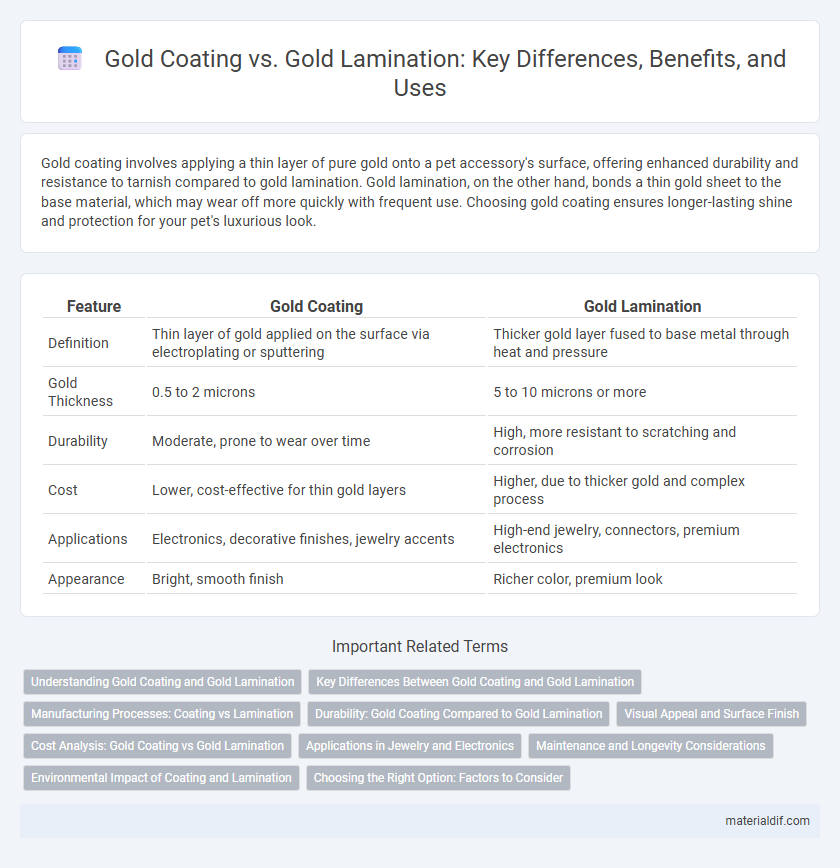

Gold coating involves applying a thin layer of pure gold onto a pet accessory's surface, offering enhanced durability and resistance to tarnish compared to gold lamination. Gold lamination, on the other hand, bonds a thin gold sheet to the base material, which may wear off more quickly with frequent use. Choosing gold coating ensures longer-lasting shine and protection for your pet's luxurious look.

Table of Comparison

| Feature | Gold Coating | Gold Lamination |

|---|---|---|

| Definition | Thin layer of gold applied on the surface via electroplating or sputtering | Thicker gold layer fused to base metal through heat and pressure |

| Gold Thickness | 0.5 to 2 microns | 5 to 10 microns or more |

| Durability | Moderate, prone to wear over time | High, more resistant to scratching and corrosion |

| Cost | Lower, cost-effective for thin gold layers | Higher, due to thicker gold and complex process |

| Applications | Electronics, decorative finishes, jewelry accents | High-end jewelry, connectors, premium electronics |

| Appearance | Bright, smooth finish | Richer color, premium look |

Understanding Gold Coating and Gold Lamination

Gold coating involves applying a thin layer of pure gold onto a surface using techniques such as electroplating or vapor deposition, enhancing corrosion resistance and aesthetic appeal. Gold lamination, on the other hand, bonds a thicker layer of gold foil or sheet to a base material under heat and pressure, providing greater durability and a more substantial gold appearance. Understanding the differences in thickness, application methods, and durability helps in selecting the right gold finish for jewelry, electronics, or decorative items.

Key Differences Between Gold Coating and Gold Lamination

Gold coating involves applying a thin layer of gold using electroplating or physical vapor deposition, creating a uniform, delicate surface layer that can wear off over time. Gold lamination bonds a thicker layer of gold to a substrate through heat and pressure, resulting in increased durability and resistance to peeling or tarnishing. Key differences include the thickness of the gold layer, longevity, and the strength of adhesion to the base material.

Manufacturing Processes: Coating vs Lamination

Gold coating involves applying a thin layer of gold onto a substrate through electroplating or sputtering, resulting in a precise, controlled thickness that enhances conductivity and corrosion resistance. Gold lamination, by contrast, bonds a thicker, pre-formed gold foil onto the substrate using heat and pressure, providing greater durability and wear resistance but with less precise thickness control. The manufacturing process of coating is often favored for intricate electronic components, while lamination suits applications requiring robust mechanical strength.

Durability: Gold Coating Compared to Gold Lamination

Gold coating offers superior durability compared to gold lamination due to its thicker layer of gold, which withstands wear and corrosion more effectively. While gold lamination involves bonding a thin gold layer to the base metal under heat, it is prone to chipping and peeling over time. The enhanced resilience of gold coating makes it ideal for high-contact applications requiring long-lasting elegance.

Visual Appeal and Surface Finish

Gold coating offers a richer visual appeal with a thicker layer that enhances luster and durability, resulting in a smooth, high-quality surface finish. Gold lamination provides a thinner, more cost-effective layer that delivers a bright appearance but may wear off faster and show less depth in texture. Both techniques improve aesthetic value, but gold coating is preferred for superior surface resilience and long-lasting shine.

Cost Analysis: Gold Coating vs Gold Lamination

Gold coating typically involves applying a thin layer of gold through electroplating or physical vapor deposition, resulting in lower material costs and less gold usage compared to gold lamination. Gold lamination, on the other hand, consists of bonding a thicker gold sheet onto a substrate, increasing durability but significantly raising production expenses due to higher gold content and more complex manufacturing processes. For businesses prioritizing cost-efficiency, gold coating offers a budget-friendly solution, while gold lamination provides enhanced quality at a premium price point.

Applications in Jewelry and Electronics

Gold coating offers a thin, pure gold layer ideal for delicate jewelry pieces requiring high conductivity and corrosion resistance, such as connectors in electronics. Gold lamination involves bonding thicker gold sheets to substrates, providing enhanced durability and luxurious aesthetics in fashion jewelry and high-performance electronic components. Both methods optimize gold usage by balancing cost, wear resistance, and functional requirements in these applications.

Maintenance and Longevity Considerations

Gold coating offers a thinner, more delicate layer of gold that requires careful maintenance to prevent tarnishing and wear, often necessitating gentle cleaning and limited exposure to harsh chemicals. Gold lamination involves bonding a thicker gold layer to the base material, providing enhanced durability and longer-lasting shine with less frequent upkeep. Both methods improve aesthetic appeal, but gold lamination typically extends the lifespan and reduces maintenance compared to gold coating.

Environmental Impact of Coating and Lamination

Gold coating involves applying a thin layer of gold through electroplating, which uses toxic chemicals and generates hazardous waste, posing significant environmental risks. Gold lamination, bonding a thicker gold foil to a base metal using heat and pressure, generally results in less chemical pollution and lower waste production. Choosing gold lamination over coating can reduce the ecological footprint by minimizing toxic effluents and energy consumption during manufacturing.

Choosing the Right Option: Factors to Consider

Gold coating offers a thin, cost-effective layer of gold ideal for decorative and conductive purposes, while gold lamination involves bonding a thicker gold layer for enhanced durability and resistance to wear. Factors to consider include the intended use, budget constraints, and required longevity, as laminated gold provides better protection in high-friction environments compared to coatings. Selecting the right option depends on the balance between aesthetic appeal and functional performance in applications such as jewelry, electronics, or industrial components.

Gold Coating vs Gold Lamination Infographic

materialdif.com

materialdif.com