Gold soldering and gold brazing are both methods used to join gold components, but they differ primarily in temperature and filler material. Gold soldering involves melting a filler metal with a lower melting point than gold, typically below 900degC, to create a precise and clean joint ideal for jewelry making. Gold brazing uses higher temperatures, above 900degC, and stronger filler metals to form more durable and robust joints suitable for industrial applications.

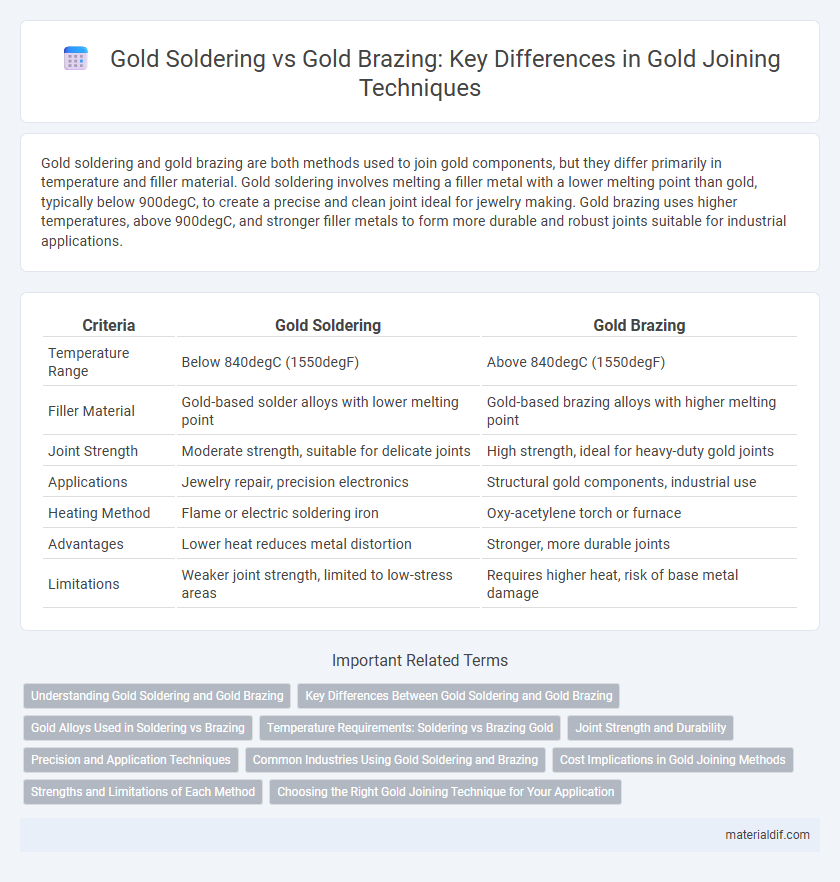

Table of Comparison

| Criteria | Gold Soldering | Gold Brazing |

|---|---|---|

| Temperature Range | Below 840degC (1550degF) | Above 840degC (1550degF) |

| Filler Material | Gold-based solder alloys with lower melting point | Gold-based brazing alloys with higher melting point |

| Joint Strength | Moderate strength, suitable for delicate joints | High strength, ideal for heavy-duty gold joints |

| Applications | Jewelry repair, precision electronics | Structural gold components, industrial use |

| Heating Method | Flame or electric soldering iron | Oxy-acetylene torch or furnace |

| Advantages | Lower heat reduces metal distortion | Stronger, more durable joints |

| Limitations | Weaker joint strength, limited to low-stress areas | Requires higher heat, risk of base metal damage |

Understanding Gold Soldering and Gold Brazing

Gold soldering involves joining gold components using a filler metal with a melting point below 840degF (450degC), ensuring delicate and precise bonds ideal for fine jewelry. Gold brazing utilizes higher temperatures, typically above 1100degF (593degC), to join gold parts with stronger, more durable joints suitable for industrial applications. Understanding the temperature ranges and joint strength differences is critical for selecting the appropriate gold joining technique.

Key Differences Between Gold Soldering and Gold Brazing

Gold soldering involves melting a filler metal with a lower melting point than gold to join pieces without melting the base metals, ensuring minimal distortion. Gold brazing requires higher temperatures, above 450degC, to fuse gold components using a gold alloy filler, producing stronger and more heat-resistant joints. The choice between soldering and brazing depends on the mechanical strength needed and the thermal sensitivity of the gold parts involved.

Gold Alloys Used in Soldering vs Brazing

Gold soldering typically utilizes low-melting-point gold alloys such as gold-silver-copper (Au-Ag-Cu) combinations with melting points below 950degC, ensuring delicate joints without compromising component integrity. Gold brazing employs higher-melting-point alloys like gold-copper-silicon (Au-Cu-Si) or gold-nickel (Au-Ni) that melt above 950degC to create stronger, more durable bonds suitable for structural applications. The choice of gold alloys influences thermal behavior, joint strength, and corrosion resistance, making alloy composition critical in differentiating soldering from brazing processes.

Temperature Requirements: Soldering vs Brazing Gold

Gold soldering typically requires temperatures ranging from 300degC to 450degC, using filler metals with a lower melting point than gold itself, ensuring delicate components are not damaged. In contrast, gold brazing demands higher temperatures between 600degC and 900degC, where the filler metal has a melting point above 450degC but below the base gold alloy, creating stronger joints suitable for structural applications. Understanding these temperature requirements is crucial for selecting the appropriate method based on component sensitivity and joint strength in gold assembly processes.

Joint Strength and Durability

Gold soldering produces joints with moderate strength suitable for delicate electronics and fine jewelry, relying on lower melting point alloys to avoid base metal distortion. Gold brazing achieves higher joint strength and superior durability by using filler metals that melt above 450degC, creating robust bonds ideal for heavy-duty applications and components exposed to mechanical stress. Brazed joints typically exhibit enhanced resistance to corrosion and thermal cycling compared to soldered joints, ensuring longer service life in demanding environments.

Precision and Application Techniques

Gold soldering offers higher precision due to its lower melting point, reducing the risk of damaging delicate components, making it ideal for fine jewelry and electronic connections. Gold brazing, with its higher melting temperatures and stronger joint strength, is better suited for applications requiring robust mechanical bonds such as industrial equipment and aerospace components. Both techniques demand careful application of heat and flux, but soldering prioritizes detail and minimal thermal impact, while brazing emphasizes durability and structural integrity.

Common Industries Using Gold Soldering and Brazing

Common industries using gold soldering include electronics, jewelry, and aerospace, where precise and delicate joining is essential for circuit boards and decorative pieces. Gold brazing finds application in the dental, automotive, and medical device sectors requiring strong, durable joints with excellent corrosion resistance. Both techniques are vital for industries emphasizing conductivity, strength, and aesthetic quality in gold components.

Cost Implications in Gold Joining Methods

Gold soldering typically involves lower temperature processes and less expensive filler materials, resulting in reduced overall costs compared to gold brazing. Gold brazing requires higher temperatures and often more costly alloys, increasing both energy consumption and material expenses. Cost implications in gold joining methods hinge on factors like equipment durability, filler metal expense, and process efficiency, making soldering more economically viable for small-scale or delicate applications.

Strengths and Limitations of Each Method

Gold soldering offers precise, low-temperature joining ideal for delicate electronic components but provides moderate mechanical strength compared to other methods. Gold brazing achieves stronger, more durable joints by using higher temperatures, making it suitable for structural applications, although it may risk heat damage to sensitive materials. Each method balances melting point control and joint integrity, selecting soldering for fine detail and brazing for enhanced strength and durability.

Choosing the Right Gold Joining Technique for Your Application

Gold soldering uses a lower melting point filler metal to join gold components, making it ideal for delicate jewelry and electronics requiring precision without damaging the base material. Gold brazing employs a higher melting temperature filler, providing stronger, more durable joints suitable for heavy-duty applications like aerospace or dental devices. Selecting the appropriate gold joining technique depends on factors such as mechanical strength requirements, thermal sensitivity of the components, and intended use environment.

Gold soldering vs Gold brazing Infographic

materialdif.com

materialdif.com