Electroplated gold offers a thicker and more durable layer of gold coating compared to flash-plated gold, making it ideal for jewelry that requires long-lasting shine and resistance to tarnish. Flash plating applies a very thin gold layer through rapid deposition, resulting in a more affordable option but with significantly less durability. Choosing electroplated gold provides better protection and a richer appearance, while flash-plated gold suits budget-friendly accessories with limited wear.

Table of Comparison

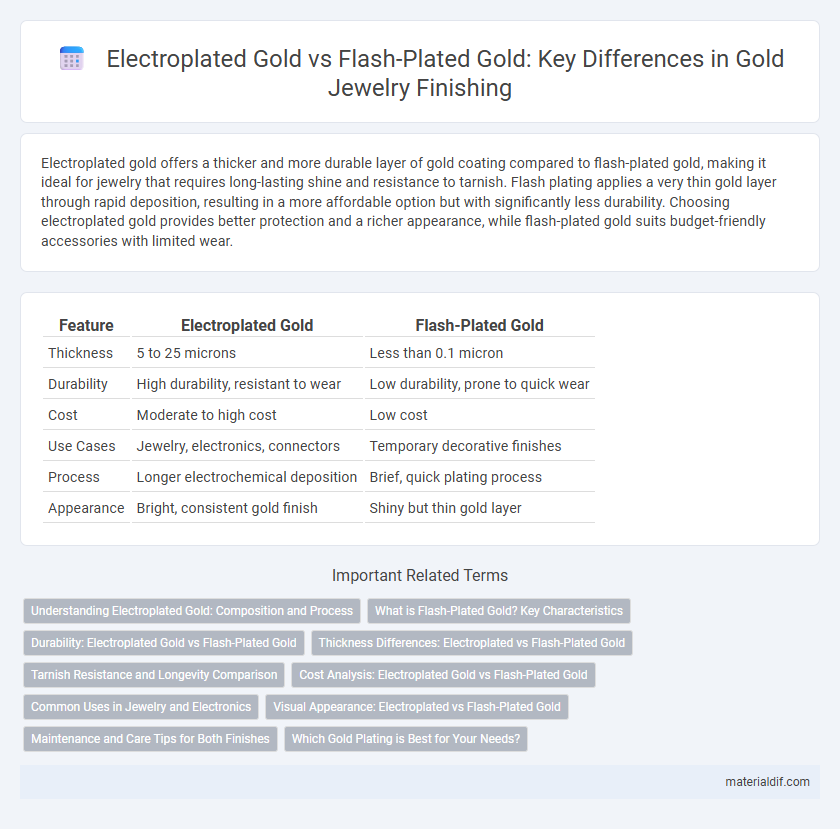

| Feature | Electroplated Gold | Flash-Plated Gold |

|---|---|---|

| Thickness | 5 to 25 microns | Less than 0.1 micron |

| Durability | High durability, resistant to wear | Low durability, prone to quick wear |

| Cost | Moderate to high cost | Low cost |

| Use Cases | Jewelry, electronics, connectors | Temporary decorative finishes |

| Process | Longer electrochemical deposition | Brief, quick plating process |

| Appearance | Bright, consistent gold finish | Shiny but thin gold layer |

Understanding Electroplated Gold: Composition and Process

Electroplated gold involves depositing a thicker layer of gold onto a base metal through an electrochemical process, typically resulting in a more durable and corrosion-resistant coating compared to flash-plated gold. The electroplating process uses an electrolyte solution containing gold ions, which are reduced onto the substrate by passing an electric current, ensuring uniform coverage and enhanced adhesion. This technique allows control over the thickness of the gold layer, commonly ranging from 0.5 to 2 microns, making electroplated gold ideal for jewelry and electronics requiring longevity.

What is Flash-Plated Gold? Key Characteristics

Flash-plated gold is a very thin layer of gold, typically less than 0.25 microns thick, applied over a base metal through electroplating to provide a decorative finish and corrosion resistance. This type of plating often lacks durability and wears off quickly compared to thicker electroplated gold coatings, making it ideal for costume jewelry or items with minimal wear. Key characteristics include low gold content, short lifespan, and a more affordable price point compared to standard electroplated gold layers.

Durability: Electroplated Gold vs Flash-Plated Gold

Electroplated gold offers significantly higher durability than flash-plated gold due to its thicker coating, which typically ranges from 2.5 to 5 microns, compared to the ultra-thin flash plating of about 0.05 microns. This substantial layer enhances resistance to wear, tarnishing, and corrosion, making electroplated gold ideal for jewelry and electronics requiring long-lasting performance. Flash-plated gold, while cost-effective and suitable for decorative purposes, tends to wear off quickly under frequent use or friction, limiting its lifespan.

Thickness Differences: Electroplated vs Flash-Plated Gold

Electroplated gold typically features a thickness ranging from 0.5 to 2 microns, providing enhanced durability and corrosion resistance compared to flash-plated gold, which usually measures less than 0.25 microns. The increased thickness in electroplated gold results in a longer lifespan and better conductivity, making it ideal for high-quality jewelry and electronic components. Flash-plated gold, while cost-effective and visually similar, offers minimal protection due to its ultrathin layer, primarily serving aesthetic purposes rather than long-term wear.

Tarnish Resistance and Longevity Comparison

Electroplated gold offers superior tarnish resistance compared to flash-plated gold due to its thicker, more uniform coating that effectively protects the underlying metal from oxidation and environmental exposure. Flash-plated gold, characterized by a very thin layer typically less than 0.1 microns, wears off quicker, resulting in reduced longevity and increased susceptibility to tarnishing. The increased thickness of electroplated gold coatings, often ranging from 0.5 to several microns, significantly extends the lifespan and maintains the aesthetic quality of jewelry and electronic components.

Cost Analysis: Electroplated Gold vs Flash-Plated Gold

Electroplated gold involves a thicker layer of gold deposition, resulting in higher material and production costs compared to flash-plated gold, which uses a very thin coating primarily for decorative purposes. The cost-efficiency of flash-plated gold suits large-scale applications where minimal gold usage is critical, whereas electroplated gold offers better durability and wear resistance, justifying its premium price in high-quality products. Evaluating cost per unit thickness reveals electroplated gold's higher upfront investment but longer lifespan, influencing long-term value in jewelry and electronics manufacturing.

Common Uses in Jewelry and Electronics

Electroplated gold is commonly used in high-quality jewelry and electronic connectors due to its thicker, durable coating that provides enhanced corrosion resistance and aesthetic appeal. Flash-plated gold, with its ultra-thin layer, is often utilized in costume jewelry and low-cost electronic contacts where minimal gold usage reduces production costs while maintaining basic conductivity and appearance. Both methods serve distinct roles in electronics and jewelry manufacturing based on the balance between cost, durability, and functionality.

Visual Appearance: Electroplated vs Flash-Plated Gold

Electroplated gold offers a thicker, more uniform layer resulting in a richer, deeper gold color with enhanced durability and luster. Flash-plated gold features a very thin coating, often yielding a lighter, less consistent hue that may wear off more quickly under regular use. The visual distinction is evident as electroplated gold maintains its vibrant appearance longer compared to the subtle, often patchy finish of flash-plated gold.

Maintenance and Care Tips for Both Finishes

Electroplated gold offers a thicker layer of gold, resulting in enhanced durability and longer-lasting shine compared to flash-plated gold, which has a thinner coating prone to faster wear. To maintain electroplated gold, gently clean with mild soap and water while avoiding abrasive materials, and store jewelry individually to prevent scratches. Flash-plated gold requires more frequent cleaning and careful handling, including avoiding exposure to water, sweat, and chemicals to preserve its delicate finish.

Which Gold Plating is Best for Your Needs?

Electroplated gold offers a thicker, more durable layer of gold compared to flash-plated gold, making it ideal for jewelry and electronics requiring long-lasting wear and corrosion resistance. Flash-plated gold features a very thin coating, best suited for decorative pieces or applications with minimal handling. Choosing between the two depends on the desired longevity and surface protection, with electroplated gold providing superior durability for frequent use.

Electroplated Gold vs Flash-Plated Gold Infographic

materialdif.com

materialdif.com