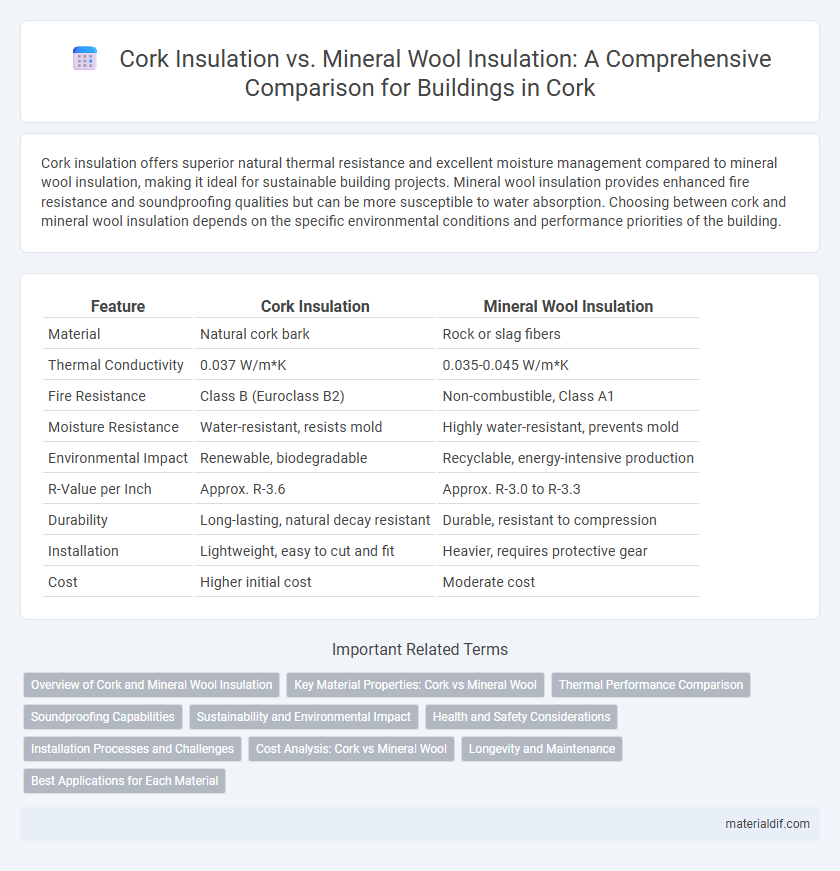

Cork insulation offers superior natural thermal resistance and excellent moisture management compared to mineral wool insulation, making it ideal for sustainable building projects. Mineral wool insulation provides enhanced fire resistance and soundproofing qualities but can be more susceptible to water absorption. Choosing between cork and mineral wool insulation depends on the specific environmental conditions and performance priorities of the building.

Table of Comparison

| Feature | Cork Insulation | Mineral Wool Insulation |

|---|---|---|

| Material | Natural cork bark | Rock or slag fibers |

| Thermal Conductivity | 0.037 W/m*K | 0.035-0.045 W/m*K |

| Fire Resistance | Class B (Euroclass B2) | Non-combustible, Class A1 |

| Moisture Resistance | Water-resistant, resists mold | Highly water-resistant, prevents mold |

| Environmental Impact | Renewable, biodegradable | Recyclable, energy-intensive production |

| R-Value per Inch | Approx. R-3.6 | Approx. R-3.0 to R-3.3 |

| Durability | Long-lasting, natural decay resistant | Durable, resistant to compression |

| Installation | Lightweight, easy to cut and fit | Heavier, requires protective gear |

| Cost | Higher initial cost | Moderate cost |

Overview of Cork and Mineral Wool Insulation

Cork insulation is a natural, renewable material harvested from the bark of cork oak trees, known for its excellent thermal insulation, soundproofing, and resistance to moisture and fire. Mineral wool insulation, made from rock or slag fibers, offers superior fire resistance and sound absorption, and is highly effective in thermal insulation, commonly used in commercial and residential buildings. Both materials provide sustainable solutions with distinct advantages, where cork excels in eco-friendliness and natural properties, while mineral wool performs better in fire safety and structural applications.

Key Material Properties: Cork vs Mineral Wool

Cork insulation offers natural thermal resistance, excellent moisture regulation, and environmental sustainability due to its renewable cork oak origin, making it lightweight and resistant to mold. Mineral wool insulation provides superior fire resistance, soundproofing, and higher density, enhancing thermal performance in industrial applications but can absorb moisture if not properly sealed. The choice between cork and mineral wool depends on balancing eco-friendliness and moisture control with fire safety and acoustic demands in building projects.

Thermal Performance Comparison

Cork insulation offers excellent thermal performance due to its natural cellular structure, which provides high thermal resistance (R-value approximately 3.6-4.2 per inch). Mineral wool insulation delivers slightly higher thermal resistance (R-value around 3.7-4.3 per inch), making it effective for heat retention and energy efficiency. Both materials provide strong insulation properties, but mineral wool may outperform cork marginally in thermal resistance under standard conditions.

Soundproofing Capabilities

Cork insulation offers natural sound absorption due to its cellular structure, effectively reducing airborne noise and vibrations. Mineral wool insulation provides superior soundproofing by trapping sound waves within its dense fibers, making it highly efficient for noise control in walls and ceilings. Both materials enhance acoustic performance, but mineral wool typically delivers higher sound attenuation levels in residential and commercial applications.

Sustainability and Environmental Impact

Cork insulation offers superior sustainability due to its renewable harvesting from cork oak trees without harming the bark, promoting carbon sequestration and biodegradability. Mineral wool insulation, derived from natural rock or recycled slag, provides excellent thermal performance but requires significant energy for production and generates less biodegradable waste. Choosing cork insulation supports lower carbon footprints and eco-friendly building practices compared to the higher embodied energy and disposal challenges linked to mineral wool.

Health and Safety Considerations

Cork insulation offers natural hypoallergenic properties and resistance to mold and pests, reducing respiratory irritation and promoting a healthier indoor environment compared to mineral wool insulation. Mineral wool can release irritant fibers and dust during installation, posing risks to skin, eyes, and lungs if proper protective equipment is not used. Proper ventilation and protective gear are essential for safely handling both materials, but cork insulation generally provides a safer option for occupants with sensitivities or allergies.

Installation Processes and Challenges

Cork insulation involves a relatively straightforward installation process, as it comes in lightweight boards or loose granules that can be easily cut and fitted into walls, floors, or ceilings without special tools. Mineral wool insulation requires precise handling to ensure proper fit and avoid gaps, and its installation often demands protective gear due to irritant fibers. Both materials present challenges in achieving airtight seals, but cork's natural compressibility provides better adaptability in irregular spaces compared to mineral wool.

Cost Analysis: Cork vs Mineral Wool

Cork insulation typically costs more upfront than mineral wool insulation, with prices ranging from $2.50 to $4.00 per square foot compared to mineral wool's $1.00 to $1.50 per square foot. Despite higher initial expenses, cork offers superior durability and thermal performance, potentially reducing long-term energy costs. Mineral wool provides a cost-effective option with good fire resistance and soundproofing but may require more frequent replacement due to moisture sensitivity.

Longevity and Maintenance

Cork insulation offers exceptional longevity due to its natural resistance to moisture, mold, and pests, often lasting over 50 years with minimal maintenance. Mineral wool insulation, while durable and fire-resistant, can degrade faster when exposed to prolonged moisture, requiring periodic inspection and potential replacement every 20-30 years. The low-maintenance nature of cork insulation makes it a cost-effective choice for long-term thermal performance in residential and commercial buildings in Cork's damp climate.

Best Applications for Each Material

Cork insulation excels in sustainable building projects due to its natural, renewable properties and superior thermal and acoustic performance, making it ideal for eco-friendly homes and soundproofing walls. Mineral wool insulation is best suited for fire-resistant applications and industrial buildings, offering excellent fire retardancy, moisture resistance, and sound absorption in commercial settings. Choosing between cork and mineral wool depends on specific needs such as environmental impact, fire safety requirements, and acoustic performance in Cork's varied construction projects.

Cork Insulation vs Mineral Wool Insulation Infographic

materialdif.com

materialdif.com