Woolen yarn is spun from carded fibers, creating a soft, airy texture ideal for warm, insulating wool pet products. Worsted yarn, made from combed fibers aligned parallel, offers a smoother, stronger finish perfect for durable and sleek wool pet accessories. Choosing between woolen and worsted yarn depends on the desired texture and durability of your pet's woolen items.

Table of Comparison

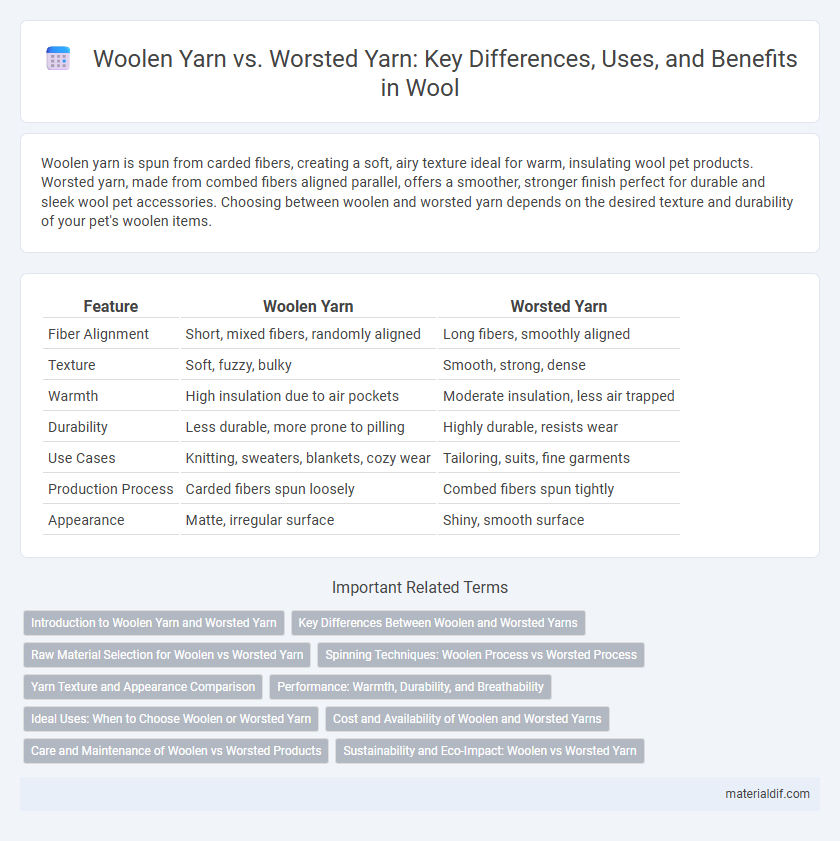

| Feature | Woolen Yarn | Worsted Yarn |

|---|---|---|

| Fiber Alignment | Short, mixed fibers, randomly aligned | Long fibers, smoothly aligned |

| Texture | Soft, fuzzy, bulky | Smooth, strong, dense |

| Warmth | High insulation due to air pockets | Moderate insulation, less air trapped |

| Durability | Less durable, more prone to pilling | Highly durable, resists wear |

| Use Cases | Knitting, sweaters, blankets, cozy wear | Tailoring, suits, fine garments |

| Production Process | Carded fibers spun loosely | Combed fibers spun tightly |

| Appearance | Matte, irregular surface | Shiny, smooth surface |

Introduction to Woolen Yarn and Worsted Yarn

Woolen yarn is made from carded fibers that remain loosely aligned, resulting in a soft, fluffy texture ideal for warm, insulating fabrics. Worsted yarn is produced from combed fibers aligned parallel, creating a smooth, strong yarn suited for fine, durable textiles. These distinct spinning techniques influence the yarn's appearance, strength, and end-use in woolen and worsted fabrics.

Key Differences Between Woolen and Worsted Yarns

Woolen yarn is made from carded fibers that are short and loosely spun, resulting in a soft, warm, and fuzzy texture ideal for insulating fabrics. Worsted yarn uses combed fibers that are long, parallel, and tightly spun, producing a smooth, strong, and durable yarn suited for fine, dense textiles. The key differences between woolen and worsted yarns lie in fiber preparation, spinning techniques, texture, strength, and typical use in garments.

Raw Material Selection for Woolen vs Worsted Yarn

Woolen yarn is produced from short-staple fibers and less combed raw wool, retaining a higher amount of natural lanolin and vegetable matter, which results in a bulkier and fuzzier texture. Worsted yarn uses long-staple fibers that are extensively combed to align fibers parallel, removing shorter fibers and impurities for a smoother, stronger, and finer yarn. The selection of raw wool plays a crucial role in determining the final yarn quality, where woolen yarn favors coarser, shorter fibers and worsted yarn requires fine, long fibers from breeds like Merino or Romney.

Spinning Techniques: Woolen Process vs Worsted Process

Woolen yarn is produced using the woolen spinning technique, where short fibers are carded and loosely twisted to create a soft, airy yarn with a fuzzy texture ideal for insulation and warmth. Worsted yarn undergoes combing to align longer fibers parallel before spinning, resulting in a smooth, strong, and durable yarn with a dense structure suited for fine, tailored garments. The woolen process emphasizes fiber bulk and elasticity, while the worsted process focuses on fiber parallelism and strength, influencing the yarn's texture and end-use applications.

Yarn Texture and Appearance Comparison

Woolen yarn features a soft, fuzzy texture with a lofty appearance due to the shorter, carded fibers that trap air, creating warmth and a slightly irregular surface. Worsted yarn is smooth, strong, and fine, made from long, combed fibers aligned parallel, resulting in a sleek, dense, and uniform texture with a polished finish. The coarser, woolen yarn is ideal for cozy, insulating fabrics, while worsted yarn suits garments requiring durability and a refined look.

Performance: Warmth, Durability, and Breathability

Woolen yarn offers superior warmth due to its loosely spun fibers that trap air, providing excellent insulation, while worsted yarn, with its tightly spun and smoother fibers, delivers greater durability and strength ideal for high-wear garments. Breathability is enhanced in woolen yarn as the airy structure allows moisture to escape more readily, whereas worsted yarn tends to be less breathable but better at retaining shape and resisting pilling. Choosing between woolen and worsted yarn depends on the desired balance of thermal insulation, fabric longevity, and moisture management for specific textile performance needs.

Ideal Uses: When to Choose Woolen or Worsted Yarn

Woolen yarn, known for its soft, lofty texture and insulating properties, is ideal for cozy garments like sweaters, scarves, and blankets that require warmth and a fuzzy appearance. Worsted yarn, spun with smooth, tightly twisted fibers, offers strength and a sleek finish, making it perfect for tailored items such as suits, fine knitting projects, and durable accessories. Choosing woolen yarn enhances softness and insulation, while worsted yarn ensures durability and smoothness in finished wool products.

Cost and Availability of Woolen and Worsted Yarns

Woolen yarn is generally more affordable and widely available due to its simpler processing method and utilization of shorter fibers, making it a cost-effective choice for bulk production. Worsted yarn, produced from longer, combed fibers with a tighter twist, tends to be more expensive and less accessible, often reserved for high-quality garments and fine textiles. The price disparity and availability directly reflect the differences in manufacturing complexity and the intended end-use of these distinct yarn types.

Care and Maintenance of Woolen vs Worsted Products

Woolen yarn products require gentle care such as hand washing in cold water with mild detergent and air drying flat to maintain their loft and softness, as machine washing can cause felting and shrinkage. Worsted yarn items benefit from more durable care methods including gentle machine washing on a wool cycle and low-heat tumble drying or flat drying, preserving their smooth texture and strength. Proper storage in a cool, dry place with moth repellents is essential for both types to prevent damage from insects and moisture.

Sustainability and Eco-Impact: Woolen vs Worsted Yarn

Woolen yarn, spun from carded fibers, retains natural air pockets that enhance insulation and durability with less mechanical processing, resulting in lower energy consumption and reduced environmental impact. Worsted yarn, made from combed long fibers, undergoes extensive processing to produce a smooth, dense texture, often leading to higher water and chemical usage compared to woolen yarn. In terms of sustainability, woolen yarn's less intensive production process and utilization of shorter fibers contribute to a more eco-friendly textile choice.

Woolen Yarn vs Worsted Yarn Infographic

materialdif.com

materialdif.com