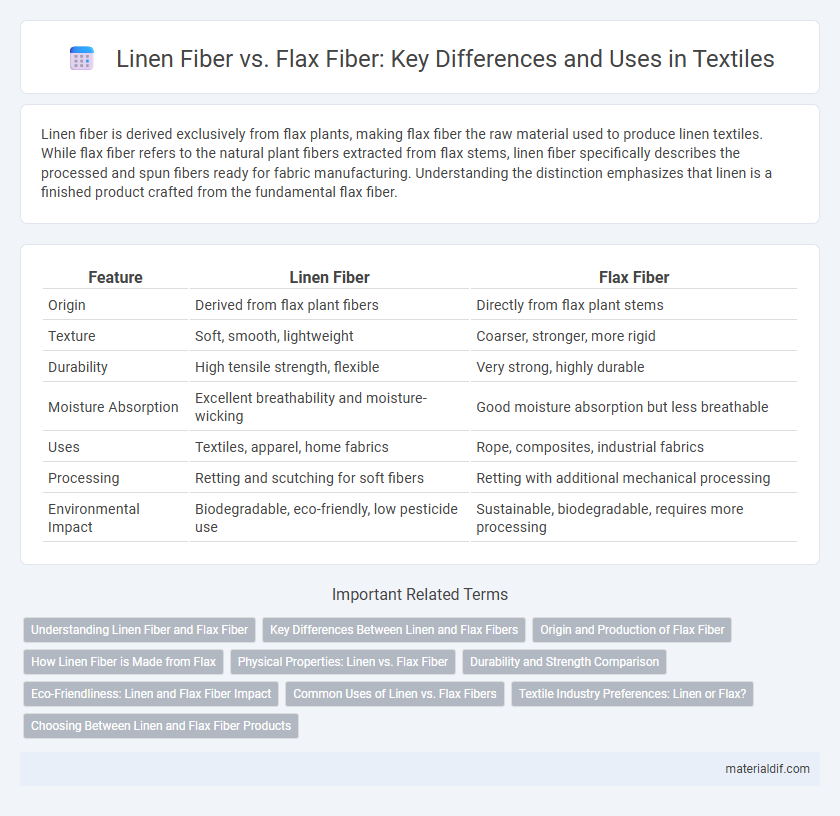

Linen fiber is derived exclusively from flax plants, making flax fiber the raw material used to produce linen textiles. While flax fiber refers to the natural plant fibers extracted from flax stems, linen fiber specifically describes the processed and spun fibers ready for fabric manufacturing. Understanding the distinction emphasizes that linen is a finished product crafted from the fundamental flax fiber.

Table of Comparison

| Feature | Linen Fiber | Flax Fiber |

|---|---|---|

| Origin | Derived from flax plant fibers | Directly from flax plant stems |

| Texture | Soft, smooth, lightweight | Coarser, stronger, more rigid |

| Durability | High tensile strength, flexible | Very strong, highly durable |

| Moisture Absorption | Excellent breathability and moisture-wicking | Good moisture absorption but less breathable |

| Uses | Textiles, apparel, home fabrics | Rope, composites, industrial fabrics |

| Processing | Retting and scutching for soft fibers | Retting with additional mechanical processing |

| Environmental Impact | Biodegradable, eco-friendly, low pesticide use | Sustainable, biodegradable, requires more processing |

Understanding Linen Fiber and Flax Fiber

Linen fiber and flax fiber both originate from the flax plant, with flax fiber referring to the raw material extracted directly from the plant's stalks and linen fiber indicating the processed and refined form used in textile production. Linen fiber is known for its strength, moisture-wicking properties, and durability, making it ideal for high-quality fabrics, while flax fiber, being less processed, retains more natural characteristics such as brittleness and uneven texture. Understanding the distinction between flax fiber and linen fiber is essential for textile manufacturers and consumers seeking premium, sustainable fabrics with specific performance qualities.

Key Differences Between Linen and Flax Fibers

Linen fiber is derived from flax plant fibers through a complex retting and processing technique, resulting in a smooth, durable textile ideal for clothing and home textiles. Flax fiber refers to the raw, untreated fibers extracted directly from the flax plant's stalk, containing more impurities and exhibiting coarser texture than processed linen. Key differences include linen's enhanced softness, higher tensile strength, and refined appearance compared to the natural, rougher state of flax fibers used primarily in industrial applications.

Origin and Production of Flax Fiber

Flax fiber, derived from the flax plant (Linum usitatissimum), originates primarily in regions such as Belgium, France, and the Netherlands, where optimal soil and climate conditions foster high-quality fiber production. The production of flax fiber involves a labor-intensive process including retting, breaking, scutching, and hackling to extract long, strong fibers ideal for linen fabric manufacturing. Unlike general linen fiber, flax fiber is specifically recognized for its natural durability and breathability, making it a preferred raw material in sustainable textile industries.

How Linen Fiber is Made from Flax

Linen fiber is produced from the flax plant, specifically extracted from the long bast fibers found beneath the flax stalk's outer layer. The production process involves harvesting flax plants, retting to loosen the fibers through microbial action or water immersion, followed by breaking and scutching to separate the fibers from woody parts. These flax fibers are then spun into linen yarn, providing the natural strength and breathability characteristic of linen fabric.

Physical Properties: Linen vs. Flax Fiber

Linen fiber, derived from flax plants, exhibits remarkable tensile strength and durability, making it highly resilient in textile applications. Flax fiber, characterized by its long, smooth strands, provides excellent moisture-wicking properties and natural luster, crucial for high-quality fabric production. Both fibers share similar physical properties, but linen's refined processing enhances its softness and flexibility compared to raw flax fiber.

Durability and Strength Comparison

Linen fiber, derived from flax plants, exhibits exceptional durability due to its long, strong fibers that resist wear and tear better than many natural textiles. Flax fiber specifically is renowned for its tensile strength, often surpassing cotton and hemp, which contributes to linen fabric's ability to withstand repeated laundering and heavy use without significant degradation. The durability and strength of flax fiber make linen an ideal choice for high-quality textiles that require longevity and resilience.

Eco-Friendliness: Linen and Flax Fiber Impact

Linen and flax fiber both originate from the flax plant, but linen is the textile made from processed flax fibers, offering exceptional eco-friendliness due to its biodegradable nature and minimal use of pesticides during cultivation. Flax fiber extraction requires less water and energy compared to cotton, contributing to a significantly lower carbon footprint in linen production. Sustainable farming practices and the durability of linen textiles enhance their positive environmental impact, making linen a preferred choice in eco-conscious fashion and home textiles.

Common Uses of Linen vs. Flax Fibers

Linen fiber, derived from flax plants, is primarily used in textile production for clothing, upholstery, and home furnishings due to its durability and breathability. Flax fiber, while closely related to linen, extends beyond textiles to applications like paper manufacturing, rope making, and composite materials in automotive industries. The diversity of flax fiber's uses contrasts with linen's specialized role in producing high-quality, natural fabric products.

Textile Industry Preferences: Linen or Flax?

Linen fiber and flax fiber originate from the same plant, but in the textile industry, the terms are often used interchangeably, with linen referring specifically to the refined fiber spun into fabric. Textile manufacturers prefer linen for its strength, breathability, and natural luster, making it ideal for high-quality garments and home textiles. Flax fiber, while raw and less processed, is valued for its sustainability and versatility in producing linen textiles, retaining eco-friendly appeal throughout the supply chain.

Choosing Between Linen and Flax Fiber Products

Linen fiber and flax fiber originate from the same plant, but linen fibers are processed to be softer and finer, making them ideal for high-quality textiles with smooth texture and durability. Flax fiber, being coarser and stronger, is commonly used in industrial applications, rope making, and canvas, offering greater tensile strength and resilience. Choosing between linen and flax fiber products depends on the desired texture, strength, and end use, with linen favored for apparel and home textiles, while flax excels in heavy-duty fabric and composite materials.

Linen Fiber vs Flax Fiber Infographic

materialdif.com

materialdif.com