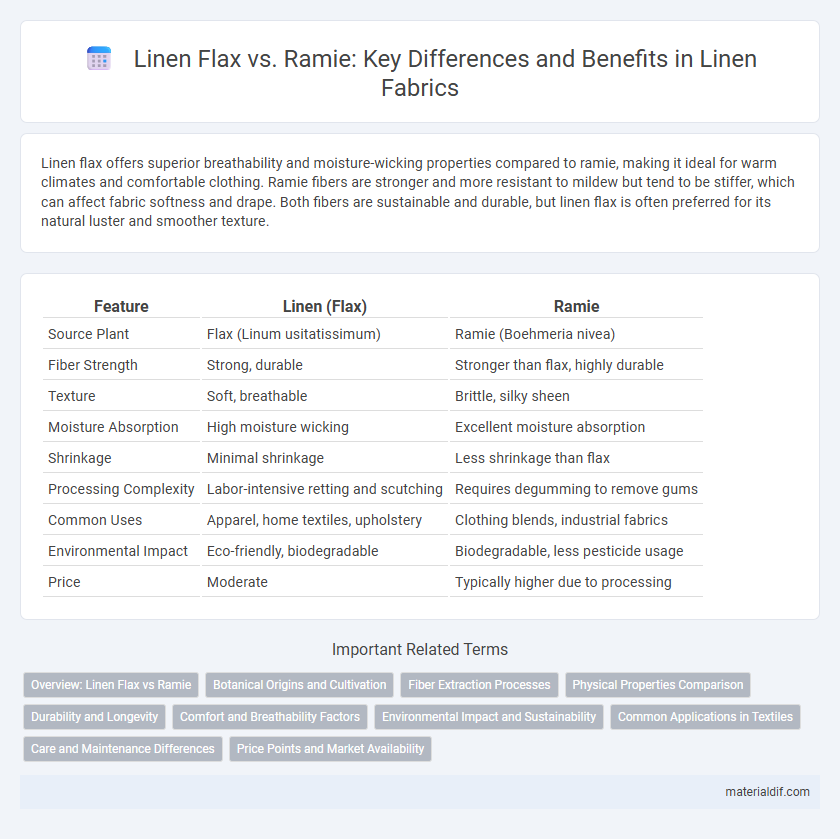

Linen flax offers superior breathability and moisture-wicking properties compared to ramie, making it ideal for warm climates and comfortable clothing. Ramie fibers are stronger and more resistant to mildew but tend to be stiffer, which can affect fabric softness and drape. Both fibers are sustainable and durable, but linen flax is often preferred for its natural luster and smoother texture.

Table of Comparison

| Feature | Linen (Flax) | Ramie |

|---|---|---|

| Source Plant | Flax (Linum usitatissimum) | Ramie (Boehmeria nivea) |

| Fiber Strength | Strong, durable | Stronger than flax, highly durable |

| Texture | Soft, breathable | Brittle, silky sheen |

| Moisture Absorption | High moisture wicking | Excellent moisture absorption |

| Shrinkage | Minimal shrinkage | Less shrinkage than flax |

| Processing Complexity | Labor-intensive retting and scutching | Requires degumming to remove gums |

| Common Uses | Apparel, home textiles, upholstery | Clothing blends, industrial fabrics |

| Environmental Impact | Eco-friendly, biodegradable | Biodegradable, less pesticide usage |

| Price | Moderate | Typically higher due to processing |

Overview: Linen Flax vs Ramie

Linen flax and ramie are both bast fibers derived from plant stalks, commonly used in textile production for their strength and durability. Linen flax, sourced from the Linum usitatissimum plant, is valued for its natural luster, breathability, and moisture-wicking properties, making it ideal for lightweight, breathable fabrics. Ramie, obtained from the Boehmeria nivea plant, features higher fiber strength and resistance to microbial damage, often blended with other fibers to enhance fabric texture and longevity.

Botanical Origins and Cultivation

Linen flax (Linum usitatissimum) belongs to the Linaceae family and thrives in temperate climates, requiring well-drained soils and moderate rainfall for optimal growth. Ramie (Boehmeria nivea), part of the Urticaceae family, prefers subtropical to tropical regions, favoring humid conditions and rich, fertile soils. Both plants are valued for their strong fibers, but their distinct botanical origins influence their cultivation techniques and environmental requirements.

Fiber Extraction Processes

Linen flax fiber extraction involves a retting process where microbial activity breaks down pectin to separate fibers from the stalk, followed by scutching and hackling to clean and align fibers. Ramie fiber extraction relies on degumming, a chemical process that removes the gummy substances binding the fibers, resulting in stronger, lustrous fibers with less retting time compared to flax. Both processes influence the fiber quality, durability, and application in textile manufacturing, with flax favoring natural enzymatic retting and ramie requiring more intensive chemical treatment.

Physical Properties Comparison

Linen flax fibers exhibit high tensile strength, excellent moisture-wicking capabilities, and a natural luster that enhances fabric durability and comfort. Ramie fibers, while also strong, are notably stiffer and more brittle, with superior resistance to bacterial attack and mildew compared to linen flax. Both fibers offer breathability and resistance to wrinkling, but linen flax provides a softer texture, making it more suitable for apparel requiring comfort.

Durability and Longevity

Linen flax is known for its exceptional durability and longevity, making it highly resistant to wear and tear over time. Ramie, while also strong, tends to be less durable than flax due to its brittleness and lower flexibility. Both fibers offer natural resistance to microbial attack, but linen flax fabrics typically maintain their structural integrity and appearance longer under regular use.

Comfort and Breathability Factors

Linen derived from flax fibers offers exceptional comfort and breathability due to its natural moisture-wicking properties and lightweight texture, making it ideal for warm climates. Ramie fibers, while also breathable and strong, tend to be stiffer and less flexible than flax linen, which can reduce comfort in direct skin contact. Flax linen's fine, smooth fibers enhance airflow and softness, outperforming ramie in terms of overall comfort and cooling effects.

Environmental Impact and Sustainability

Linen flax and ramie both offer sustainable alternatives in the textile industry, but linen flax is often favored for its lower environmental impact due to its natural resistance to pests which reduces the need for pesticides, and its ability to thrive on less water compared to ramie. Ramie requires more intensive chemical processing to remove its stiff fibers, leading to higher water pollution and energy consumption. Cultivating linen flax typically results in better soil health and lower carbon emissions, making it a more eco-friendly choice for sustainable fabric production.

Common Applications in Textiles

Linen flax and ramie are both natural fibers widely used in textile manufacturing for their durability and breathability. Linen flax is primarily used in clothing, upholstery, and bed linens due to its moisture-wicking properties and smooth texture. Ramie is commonly found in blended fabrics for lightweight garments, home textiles, and industrial sewing threads because of its strength and resistance to bacterial attack.

Care and Maintenance Differences

Linen flax fabric requires gentle washing in cold water and air drying to maintain its breathability and texture, while ramie demands more durable care, tolerating warm water washes and mild chemicals without damage. Ramie fibers resist wrinkles and mildew better than linen flax, reducing the need for frequent ironing and special storage conditions. Both fabrics benefit from avoiding bleach and high heat, but linen flax's delicate nature calls for more cautious handling to preserve its softness and durability over time.

Price Points and Market Availability

Linen flax typically commands higher price points due to its premium fiber quality and widespread demand, while ramie is generally more affordable yet less prevalent in the global textile market. Market availability for linen flax is extensive, supported by established cultivation regions in Europe and North America, whereas ramie production is concentrated mainly in China and Southeast Asia, limiting its accessibility. Both fibers offer sustainable alternatives, but linen flax's broader market presence drives a stronger price premium.

Linen Flax vs Ramie Infographic

materialdif.com

materialdif.com