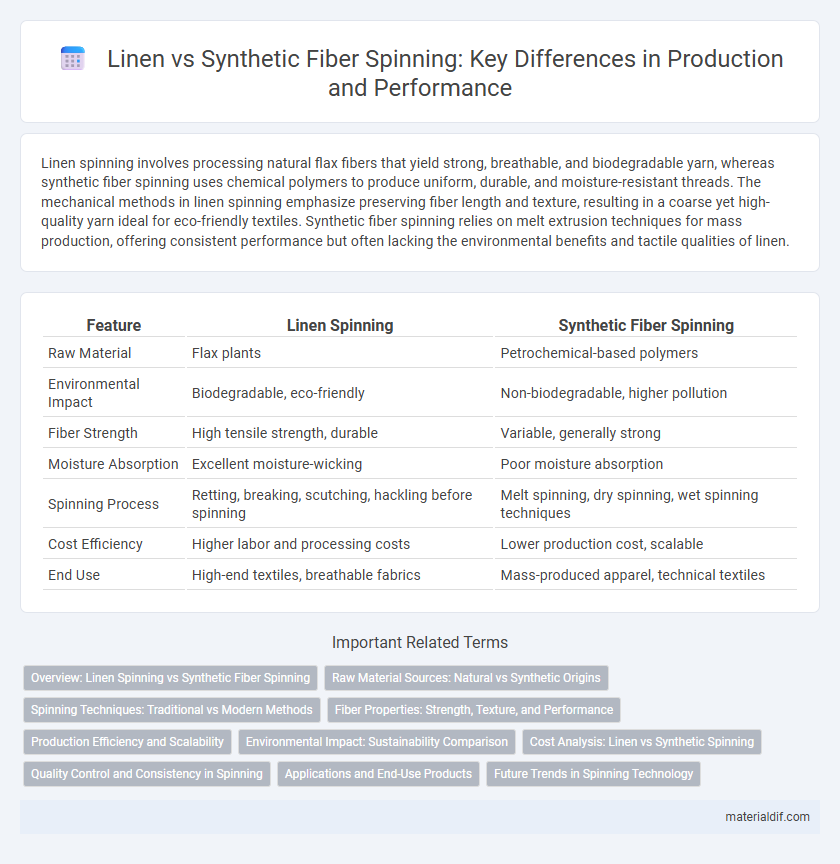

Linen spinning involves processing natural flax fibers that yield strong, breathable, and biodegradable yarn, whereas synthetic fiber spinning uses chemical polymers to produce uniform, durable, and moisture-resistant threads. The mechanical methods in linen spinning emphasize preserving fiber length and texture, resulting in a coarse yet high-quality yarn ideal for eco-friendly textiles. Synthetic fiber spinning relies on melt extrusion techniques for mass production, offering consistent performance but often lacking the environmental benefits and tactile qualities of linen.

Table of Comparison

| Feature | Linen Spinning | Synthetic Fiber Spinning |

|---|---|---|

| Raw Material | Flax plants | Petrochemical-based polymers |

| Environmental Impact | Biodegradable, eco-friendly | Non-biodegradable, higher pollution |

| Fiber Strength | High tensile strength, durable | Variable, generally strong |

| Moisture Absorption | Excellent moisture-wicking | Poor moisture absorption |

| Spinning Process | Retting, breaking, scutching, hackling before spinning | Melt spinning, dry spinning, wet spinning techniques |

| Cost Efficiency | Higher labor and processing costs | Lower production cost, scalable |

| End Use | High-end textiles, breathable fabrics | Mass-produced apparel, technical textiles |

Overview: Linen Spinning vs Synthetic Fiber Spinning

Linen spinning involves extracting fibers from flax plants, resulting in a natural, biodegradable textile with high tensile strength and breathability. Synthetic fiber spinning relies on chemical processes to produce fibers like polyester and nylon, offering uniformity, durability, and resistance to moisture and stains. While linen spinning emphasizes eco-friendly production and comfort, synthetic fiber spinning prioritizes scalability and cost-effectiveness in textile manufacturing.

Raw Material Sources: Natural vs Synthetic Origins

Linen spinning utilizes flax fibers derived directly from the flax plant, emphasizing a renewable and biodegradable raw material source. Synthetic fiber spinning relies on petrochemical-based polymers such as polyester or nylon, which originate from non-renewable fossil fuels. The natural origin of linen contributes to its breathability and environmental sustainability compared to the energy-intensive production of synthetic fibers.

Spinning Techniques: Traditional vs Modern Methods

Linen spinning relies on traditional methods such as water retting, scutching, and hackling to extract long, strong fibers from flax plants, resulting in a high-quality, breathable textile. Synthetic fiber spinning employs modern techniques like melt spinning and electrospinning, enabling mass production of uniform, versatile fibers with controlled properties. The contrast between linen's artisanal, labor-intensive spinning and synthetic fibers' mechanized, efficient processes highlights the balance between natural fiber quality and industrial scalability.

Fiber Properties: Strength, Texture, and Performance

Linen spinning produces fibers with exceptional tensile strength, natural breathability, and a distinct coarse texture that enhances durability and comfort in textile applications. Synthetic fiber spinning typically yields fibers with uniform consistency, higher elasticity, and moisture-wicking properties, but lacks the natural texture and eco-friendly attributes of linen. The performance of linen fibers excels in moisture absorption and thermal regulation, while synthetic fibers offer superior resistance to abrasion and stretch.

Production Efficiency and Scalability

Linen spinning involves the mechanical processing of flax fibers, which requires longer preparation time and careful handling, resulting in lower production efficiency compared to synthetic fiber spinning. Synthetic fibers are produced through chemical extrusion processes that allow continuous, high-speed production with greater scalability to meet large-scale demand. The durability and uniformity of synthetic fibers facilitate automated spinning, significantly reducing labor costs and increasing throughput relative to traditional linen processing.

Environmental Impact: Sustainability Comparison

Linen spinning, derived from flax plants, offers a significantly lower environmental footprint compared to synthetic fiber spinning, which relies on petroleum-based resources contributing to higher carbon emissions and non-biodegradable waste. Linen production involves natural retting and fewer chemical treatments, enabling biodegradability and soil enrichment after disposal, whereas synthetic fibers often persist in ecosystems, causing microplastic pollution. The water and energy consumption in linen processing is substantially less than synthetic fiber manufacturing, positioning linen as a more sustainable choice for eco-conscious textile production.

Cost Analysis: Linen vs Synthetic Spinning

Linen spinning incurs higher production costs due to labor-intensive processes and slower fiber extraction compared to synthetic fiber spinning, which benefits from automated, large-scale manufacturing. Synthetic fibers typically offer lower raw material costs and consistent quality, reducing overall expenses in spinning operations. However, linen's natural durability and biodegradability may justify its premium cost in sustainable textile markets.

Quality Control and Consistency in Spinning

Linen spinning involves natural fiber variability that requires rigorous quality control to maintain consistent thread strength, fineness, and uniformity, often achieved through careful fiber selection and skilled processing. Synthetic fiber spinning offers higher consistency due to controlled manufacturing processes, resulting in uniform filament diameter and tensile properties. Quality control in linen spinning focuses on managing natural irregularities, while synthetic spinning emphasizes precise parameter regulation for reproducible quality.

Applications and End-Use Products

Linen spinning produces fibers with high breathability and moisture-wicking properties, making it ideal for summer clothing, home textiles, and eco-friendly upholstery. Synthetic fiber spinning offers durability and elasticity, favored in activewear, industrial fabrics, and technical textiles requiring enhanced strength and stretch. Linen's natural texture suits luxury bedding and handwoven products, whereas synthetic fibers dominate mass-produced apparel and performance-based end-use items.

Future Trends in Spinning Technology

Linen spinning is evolving with innovations like eco-friendly enzymes and advanced combing techniques that enhance fiber strength and texture, positioning it as a sustainable alternative to synthetic fiber spinning, which increasingly integrates automation and chemical treatments for mass production efficiency. Future trends in spinning technology emphasize reducing environmental impact through biodegradable processes and energy-efficient machinery, driving a shift towards natural fibers like linen for high-performance textiles. Smart spinning systems combining IoT and AI are set to optimize production precision and resource management across both linen and synthetic fiber spinning industries.

Linen Spinning vs Synthetic Fiber Spinning Infographic

materialdif.com

materialdif.com