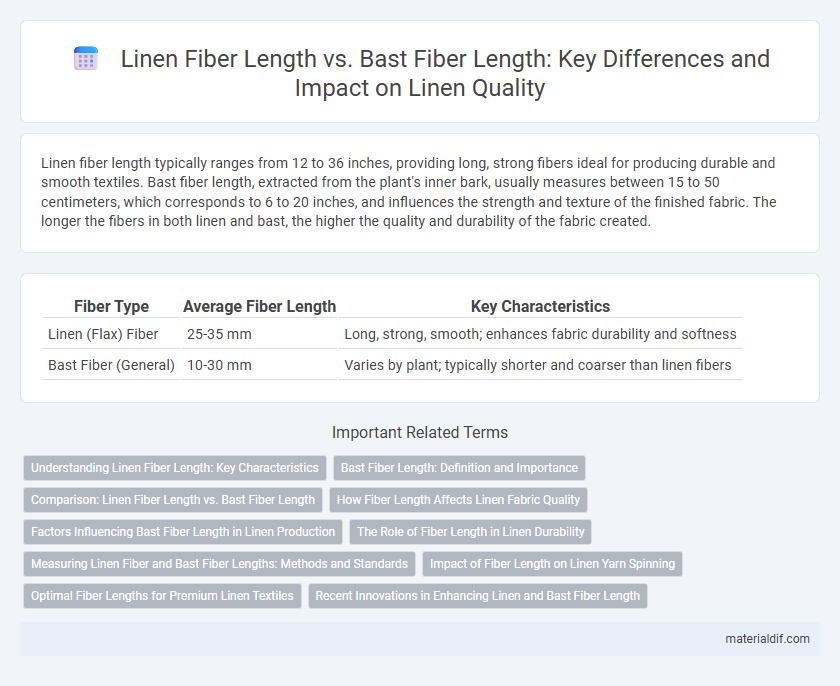

Linen fiber length typically ranges from 12 to 36 inches, providing long, strong fibers ideal for producing durable and smooth textiles. Bast fiber length, extracted from the plant's inner bark, usually measures between 15 to 50 centimeters, which corresponds to 6 to 20 inches, and influences the strength and texture of the finished fabric. The longer the fibers in both linen and bast, the higher the quality and durability of the fabric created.

Table of Comparison

| Fiber Type | Average Fiber Length | Key Characteristics |

|---|---|---|

| Linen (Flax) Fiber | 25-35 mm | Long, strong, smooth; enhances fabric durability and softness |

| Bast Fiber (General) | 10-30 mm | Varies by plant; typically shorter and coarser than linen fibers |

Understanding Linen Fiber Length: Key Characteristics

Linen fiber length typically ranges from 25 to 40 inches, significantly longer than most bast fibers, which usually measure around 12 to 36 inches. This extended fiber length contributes to linen's strength, durability, and smooth texture, making it ideal for high-quality textiles. Understanding variations in linen fiber length is essential for optimizing fabric performance and ensuring superior end products.

Bast Fiber Length: Definition and Importance

Bast fiber length refers to the measurement of fibers extracted from the outer stem of the flax plant, which is significantly longer than other fiber types, often reaching lengths of 25 to 150 millimeters. This length is crucial in linen production because longer bast fibers contribute to the fabric's strength, durability, and smooth texture. Evaluating bast fiber length ensures high-quality linen with superior tensile strength and enhanced wear resistance.

Comparison: Linen Fiber Length vs. Bast Fiber Length

Linen fiber length typically ranges from 25 to 30 inches, providing superior strength and durability compared to shorter bast fibers, which generally measure around 3 to 36 inches depending on the plant source. The longer length of linen fibers contributes to enhanced fabric smoothness, tensile strength, and reduced pilling, distinguishing linen textiles from other bast fiber products like jute or hemp. Understanding the variance in fiber length is crucial for textile manufacturers aiming to optimize fabric quality and durability in linen-based products.

How Fiber Length Affects Linen Fabric Quality

Linen fiber length directly influences the strength, smoothness, and durability of the final fabric, with longer fibers producing finer, stronger yarns ideal for high-quality textiles. Bast fibers, extracted from the flax plant's stem, vary in length but longer bast fibers result in fewer fiber ends, reducing pilling and enhancing fabric longevity. Consistent long fiber length contributes to improved linen softness and breathability, making it preferable for premium clothing and home textiles.

Factors Influencing Bast Fiber Length in Linen Production

Bast fiber length in linen production varies significantly due to factors such as flax variety, growing conditions, and harvesting techniques. Longer bast fibers result from optimal soil quality, adequate moisture, and timely retting processes that facilitate fiber separation. Mechanical extraction methods and post-harvest treatments also impact the retention of fiber length, influencing linen's overall strength and quality.

The Role of Fiber Length in Linen Durability

Linen fiber length typically ranges from 25 to 90 millimeters, significantly influencing the fabric's strength and durability compared to shorter bast fibers, which measure around 10 to 30 millimeters. Longer linen fibers allow for smoother spinning and tighter yarns, resulting in enhanced tensile strength and resistance to wear over time. The superior fiber length of flax bast fibers contributes directly to linen's renowned longevity and durability in textile applications.

Measuring Linen Fiber and Bast Fiber Lengths: Methods and Standards

Measuring linen fiber length and bast fiber length involves standardized methods such as the ASTM D1445 and ISO 13015 protocols, which ensure consistency by defining fiber sample preparation and testing procedures. Tools like fiber length analyzers and microscopic measurement techniques accurately assess individual and aggregate fiber lengths, crucial for evaluating linen quality and processing performance. Precise measurement of bast fiber length directly impacts the textile industry's ability to optimize spinning, weaving, and producing high-grade linen fabrics.

Impact of Fiber Length on Linen Yarn Spinning

Linen fiber length, typically ranging from 25 to 35 centimeters, directly influences the quality and strength of the yarn produced during spinning. Bast fibers, extracted from flax plants, vary in length but longer fibers contribute to smoother and more durable linen yarns by reducing fiber ends and enhancing fiber alignment. The consistency in bast fiber length is crucial for achieving high tensile strength and fine texture in linen textile manufacturing.

Optimal Fiber Lengths for Premium Linen Textiles

Optimal fiber length for premium linen textiles typically ranges between 25 to 40 millimeters for linen fibers, offering superior strength and smoothness compared to bast fibers, which average shorter lengths around 15 to 30 millimeters. Longer linen fibers contribute to enhanced durability, a finer texture, and improved fabric drape, essential for high-quality textile production. Selecting flax fibers with length consistency ensures a luxurious finish and maximizes the mechanical properties vital to premium linen fabrics.

Recent Innovations in Enhancing Linen and Bast Fiber Length

Recent innovations in enhancing linen and bast fiber length revolve around advanced breeding techniques and enzymatic treatments that optimize fiber extraction without compromising strength. Genetic modification has led to flax varieties yielding longer and more uniform fibers, improving the quality of linen textiles. Enzymatic retting processes also allow precise control over fiber separation, resulting in extended bast fibers that enhance fabric durability and softness.

Linen Fiber Length vs Bast Fiber Length Infographic

materialdif.com

materialdif.com