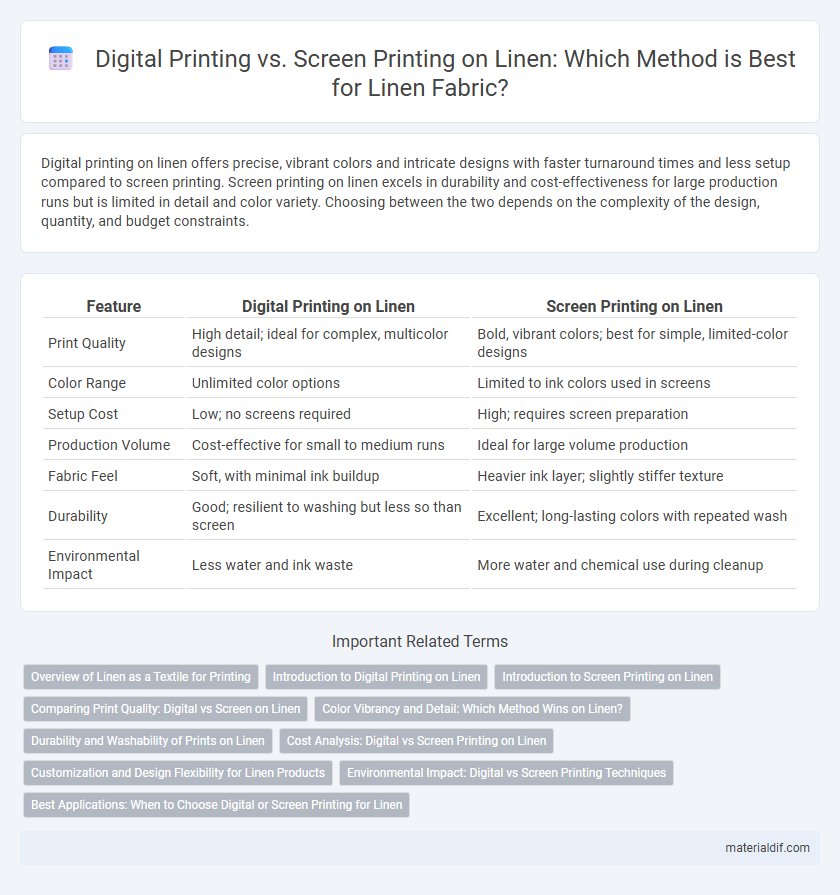

Digital printing on linen offers precise, vibrant colors and intricate designs with faster turnaround times and less setup compared to screen printing. Screen printing on linen excels in durability and cost-effectiveness for large production runs but is limited in detail and color variety. Choosing between the two depends on the complexity of the design, quantity, and budget constraints.

Table of Comparison

| Feature | Digital Printing on Linen | Screen Printing on Linen |

|---|---|---|

| Print Quality | High detail; ideal for complex, multicolor designs | Bold, vibrant colors; best for simple, limited-color designs |

| Color Range | Unlimited color options | Limited to ink colors used in screens |

| Setup Cost | Low; no screens required | High; requires screen preparation |

| Production Volume | Cost-effective for small to medium runs | Ideal for large volume production |

| Fabric Feel | Soft, with minimal ink buildup | Heavier ink layer; slightly stiffer texture |

| Durability | Good; resilient to washing but less so than screen | Excellent; long-lasting colors with repeated wash |

| Environmental Impact | Less water and ink waste | More water and chemical use during cleanup |

Overview of Linen as a Textile for Printing

Linen, derived from flax fibers, boasts a natural strength and absorbency that makes it an ideal textile for both digital and screen printing techniques. Its textured surface enhances the vibrancy and durability of digital prints, allowing for intricate designs with a wide color gamut. Screen printing on linen offers bold and opaque colors, leveraging the fabric's breathability to ensure lasting wear and comfort in garments and home textiles.

Introduction to Digital Printing on Linen

Digital printing on linen offers high-resolution, full-color designs directly applied to the fabric, preserving the linen's natural texture and breathability. This method enables intricate patterns and photographic images with a wide color gamut, making it ideal for detailed and vibrant artwork on linen garments and home textiles. Compared to traditional screen printing, digital printing reduces setup time and allows for cost-effective small-batch production, enhancing customization possibilities.

Introduction to Screen Printing on Linen

Screen printing on linen involves pushing ink through a mesh stencil to create bold, vibrant designs with excellent durability and color vibrancy. This technique is ideal for larger runs due to its cost efficiency and ability to produce consistent, high-quality prints that maintain the natural texture and breathability of linen fabric. Screen printing delivers strong adhesion and long-lasting prints, making it a preferred method for custom linens, apparel, and home textiles.

Comparing Print Quality: Digital vs Screen on Linen

Digital printing on linen offers high-resolution images with intricate details and a wide color gamut, making it ideal for complex designs and photographic prints. Screen printing on linen produces vibrant, bold colors with excellent durability, especially suitable for simple, solid color designs and large print runs. While digital printing excels in fine detail and gradient transitions, screen printing provides superior color intensity and longevity on linen fabric.

Color Vibrancy and Detail: Which Method Wins on Linen?

Digital printing on linen delivers superior color vibrancy and intricate detail due to its ability to reproduce high-resolution images with a wide color gamut, preserving the fabric's natural texture without heavy ink layering. Screen printing often results in bolder colors but can lose subtle gradients and fine detail because of thicker ink deposits and limited color matching capabilities. For projects requiring precise imagery and vibrant tones on linen, digital printing consistently outperforms screen printing.

Durability and Washability of Prints on Linen

Digital printing on linen offers vibrant colors with high detail but may have slightly lower durability compared to screen printing, especially after multiple washes. Screen printing embeds thicker layers of ink into the linen fibers, resulting in superior washability and long-lasting prints that resist fading over time. For applications demanding maximum print longevity and frequent laundering, screen printing remains the preferred method on linen fabrics.

Cost Analysis: Digital vs Screen Printing on Linen

Digital printing on linen offers lower initial setup costs compared to screen printing, which requires expensive screens and plates for each design. Screen printing becomes more cost-effective for large production runs due to economies of scale, while digital printing is ideal for small batches or highly detailed, multi-colored designs. Variable costs such as ink consumption and fabric pre-treatment impact both methods, but digital printing generally incurs higher per-unit costs on bulk orders.

Customization and Design Flexibility for Linen Products

Digital printing on linen offers superior customization and design flexibility, enabling intricate patterns, gradients, and a broader color spectrum without additional setup costs, ideal for small to medium runs. Screen printing on linen excels in producing vibrant, durable designs with high ink opacity, but it requires separate screens for each color, making it less efficient for highly detailed or multi-colored custom designs. For unique, detailed linen products with varied color schemes, digital printing is more adaptable, whereas screen printing suits bold, repetitive designs with limited color palettes.

Environmental Impact: Digital vs Screen Printing Techniques

Digital printing on linen significantly reduces water consumption and chemical waste compared to traditional screen printing, which typically involves large amounts of water and solvent-based inks. Screen printing's use of plastisol inks and extensive setup processes contributes to higher environmental pollution and energy consumption. Choosing digital printing on linen supports sustainable textile production by minimizing hazardous emissions and resource usage.

Best Applications: When to Choose Digital or Screen Printing for Linen

Digital printing on linen excels for intricate, multi-color designs and short runs, offering high resolution and quick turnaround times ideal for custom or limited-edition products. Screen printing suits large batches and simple, bold designs, providing durable ink adhesion and vibrant colors perfect for textiles like tablecloths, curtains, and apparel where longevity is key. Choosing between digital and screen printing depends on design complexity, volume, and desired durability for linen applications.

Digital Printing on Linen vs Screen Printing on Linen Infographic

materialdif.com

materialdif.com