Linen softening improves fabric pliability by relaxing fibers, resulting in a smoother, more comfortable texture ideal for garments and home textiles. Milling, a more intensive process, thickens and tightens linen fibers through controlled shrinkage, enhancing durability and creating a denser, felt-like fabric. Choosing between softening and milling depends on the desired end-use, whether prioritizing softness or robust texture.

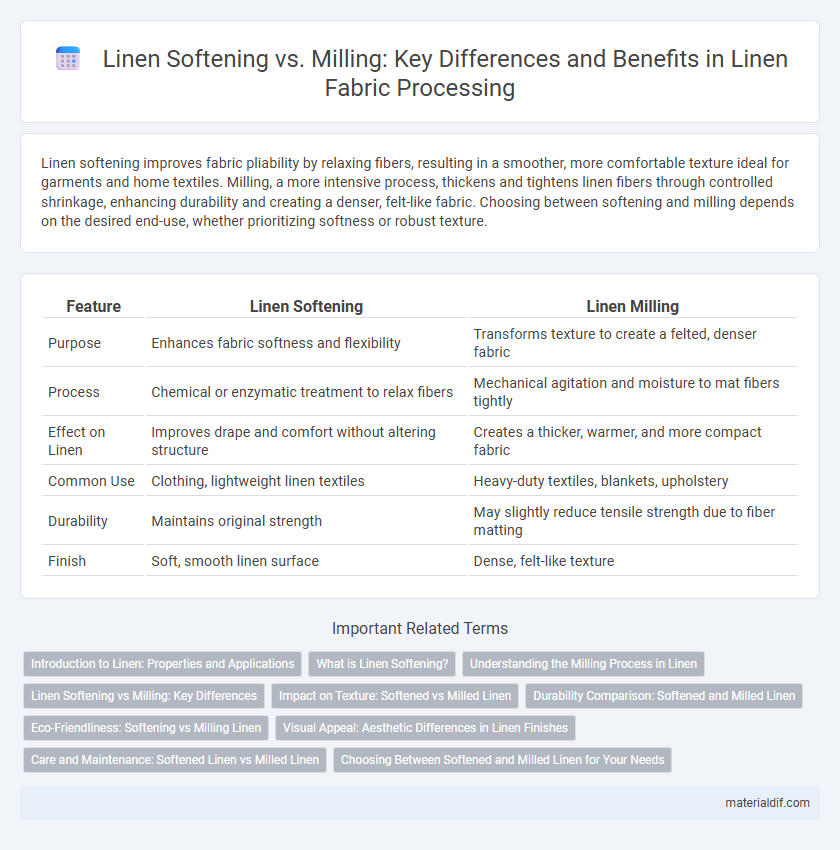

Table of Comparison

| Feature | Linen Softening | Linen Milling |

|---|---|---|

| Purpose | Enhances fabric softness and flexibility | Transforms texture to create a felted, denser fabric |

| Process | Chemical or enzymatic treatment to relax fibers | Mechanical agitation and moisture to mat fibers tightly |

| Effect on Linen | Improves drape and comfort without altering structure | Creates a thicker, warmer, and more compact fabric |

| Common Use | Clothing, lightweight linen textiles | Heavy-duty textiles, blankets, upholstery |

| Durability | Maintains original strength | May slightly reduce tensile strength due to fiber matting |

| Finish | Soft, smooth linen surface | Dense, felt-like texture |

Introduction to Linen: Properties and Applications

Linen, derived from the flax plant, is prized for its strength, breathability, and natural luster, making it a preferred fabric in apparel and home textiles. Softening enhances linen's pliability and comfort by reducing stiffness without compromising durability, while milling, or fulling, thickens and strengthens the fabric by matting fibers together. These processes significantly influence linen's texture and performance, catering to diverse applications from lightweight garments to heavy-duty upholstery.

What is Linen Softening?

Linen softening is a textile finishing process that enhances the fabric's flexibility and smoothness by relaxing the flax fibers without significantly altering the weave structure. This treatment improves the comfort and drape of linen, making it more suitable for apparel and home textiles. Linen softening typically involves enzymatic or chemical agents that target lignin and pectin, reducing stiffness while preserving the fabric's natural durability and breathability.

Understanding the Milling Process in Linen

Milling in linen involves a controlled shrinking and fulling process that enhances the fabric's texture and durability by compacting the fibers and increasing fabric density. This process improves the linen's softness and thickness while maintaining breathability, distinguishing it from simple softening treatments that only focus on surface feel. Understanding milling is essential for producing high-quality linen with enhanced strength and a smoother hand, ideal for premium textiles and apparel.

Linen Softening vs Milling: Key Differences

Linen softening involves enzymatic or chemical treatments that enhance fabric pliability and smoothness without altering the fiber's structural integrity, whereas milling is a mechanical finishing process that compacts and thickens the linen by controlled agitation and moisture application. Softening primarily improves tactile cushioning and drape, while milling increases fabric density, warmth, and durability but may reduce flexibility. Understanding these differences helps manufacturers tailor linen products for specific end uses, balancing softness and robustness.

Impact on Texture: Softened vs Milled Linen

Softened linen undergoes a gentle treatment that enhances its suppleness and smooth texture, making the fabric more comfortable and breathable. Milled linen experiences a fulling process that thickens the fibers, resulting in a denser, more textured, and slightly felted surface. The impact on texture distinguishes softened linen as lightweight and silky, while milled linen offers durability with a structured, cozy feel.

Durability Comparison: Softened and Milled Linen

Softened linen undergoes a gentle treatment preserving fiber flexibility while enhancing comfort, which maintains its inherent durability through less fiber breakage. Milled linen experiences a fulling process that compacts fibers, resulting in a denser and more robust fabric with increased resistance to wear and tear. Comparing durability, milled linen typically offers superior longevity due to enhanced fiber bonding, whereas softened linen balances softness with moderate durability suitable for everyday use.

Eco-Friendliness: Softening vs Milling Linen

Linen softening uses natural enzymes and eco-friendly softeners that reduce water and chemical consumption, making it a sustainable choice. Milling involves mechanical felting, which can increase energy use and fabric waste, impacting environmental footprint. Choosing softening over milling helps preserve linen's durability while minimizing ecological impact through gentler processing methods.

Visual Appeal: Aesthetic Differences in Linen Finishes

Linen softening enhances fabric smoothness and imparts a gentle, matte finish that highlights the natural texture of the fibers, creating a refined and subtle aesthetic. Milling transforms linen with controlled shrinkage and felting, resulting in a denser, more robust surface that offers a slightly glossy, polished look and improved durability. The choice between softening and milling significantly affects the visual appeal, with softening emphasizing lightness and tactile softness, while milling provides a richer, more structured appearance.

Care and Maintenance: Softened Linen vs Milled Linen

Softened linen maintains a smooth, supple texture that requires gentle washing with mild detergents to preserve its softness and natural fibers. Milled linen undergoes a fulling process, resulting in a denser, felt-like fabric that is more durable and less prone to wrinkling, but demands careful laundering to avoid shrinking or felting. Proper care for both softened and milled linen includes air drying and avoiding high heat to extend fabric longevity and maintain optimal texture.

Choosing Between Softened and Milled Linen for Your Needs

Choosing between softened and milled linen depends on the desired texture and durability for your project. Softened linen undergoes a process that makes it smoother and more pliable, ideal for clothing and bedding where comfort is key. Milled linen is treated with heat and pressure to create a denser, more durable fabric suited for upholstery and heavy-duty textiles requiring added strength.

Linen Softening vs Milling Infographic

materialdif.com

materialdif.com