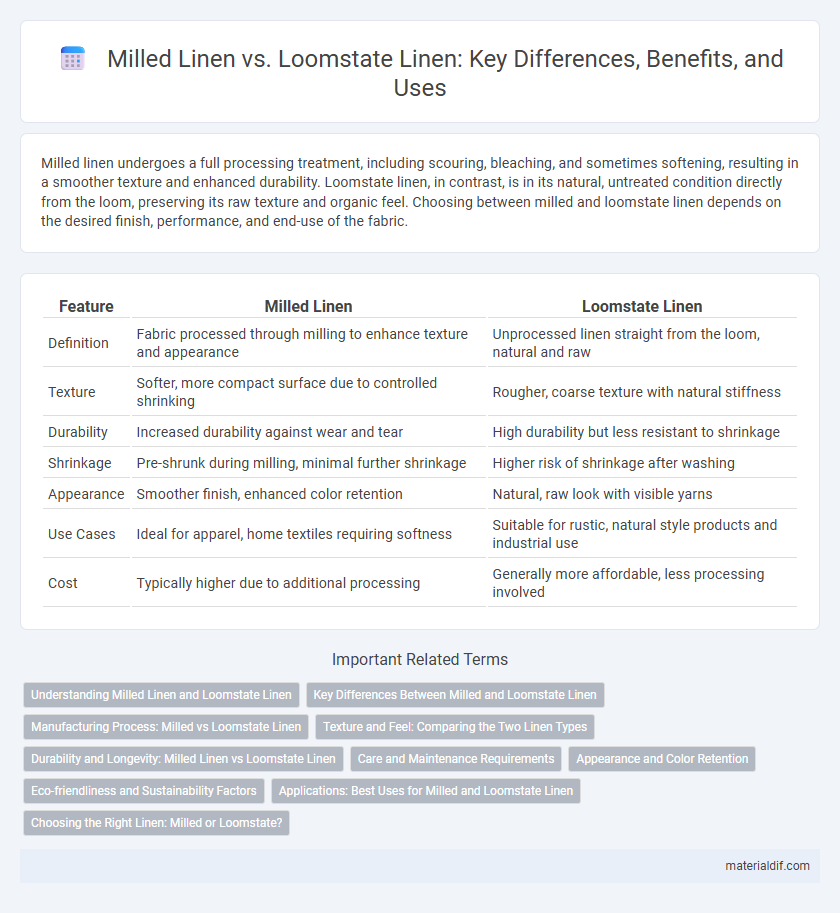

Milled linen undergoes a full processing treatment, including scouring, bleaching, and sometimes softening, resulting in a smoother texture and enhanced durability. Loomstate linen, in contrast, is in its natural, untreated condition directly from the loom, preserving its raw texture and organic feel. Choosing between milled and loomstate linen depends on the desired finish, performance, and end-use of the fabric.

Table of Comparison

| Feature | Milled Linen | Loomstate Linen |

|---|---|---|

| Definition | Fabric processed through milling to enhance texture and appearance | Unprocessed linen straight from the loom, natural and raw |

| Texture | Softer, more compact surface due to controlled shrinking | Rougher, coarse texture with natural stiffness |

| Durability | Increased durability against wear and tear | High durability but less resistant to shrinkage |

| Shrinkage | Pre-shrunk during milling, minimal further shrinkage | Higher risk of shrinkage after washing |

| Appearance | Smoother finish, enhanced color retention | Natural, raw look with visible yarns |

| Use Cases | Ideal for apparel, home textiles requiring softness | Suitable for rustic, natural style products and industrial use |

| Cost | Typically higher due to additional processing | Generally more affordable, less processing involved |

Understanding Milled Linen and Loomstate Linen

Milled linen undergoes a controlled mechanical process that compacts and softens the fabric, enhancing its texture and durability while retaining natural breathability. Loomstate linen refers to fabric in its original, untreated condition directly off the loom, preserving maximum stiffness and natural fiber structure for further customization. Understanding the distinction between milled and loomstate linen is essential for selecting fabric tailored to specific textile applications and desired aesthetic qualities.

Key Differences Between Milled and Loomstate Linen

Milled linen undergoes a mechanical process that softens the fabric and enhances its texture by tightening the fibers, resulting in a smoother, more refined appearance. Loomstate linen is unprocessed straight from the loom, retaining its natural stiffness, visible weave, and more rustic, authentic texture. The key differences lie in milled linen's improved softness and durability, whereas loomstate linen offers a more natural, raw look with a higher potential for shrinkage during washing.

Manufacturing Process: Milled vs Loomstate Linen

Milled linen undergoes a mechanical fulling process that compacts the fibers, enhancing softness and durability through controlled agitation and moisture. Loomstate linen remains unprocessed after weaving, preserving its natural stiffness and raw texture without undergoing any washing or milling. The milling process imparts a refined finish and improved drape, whereas loomstate linen retains its original characteristics for a more rigid and rustic appearance.

Texture and Feel: Comparing the Two Linen Types

Milled linen features a softer, more refined texture due to the mechanical treatment that smooths the fibers, resulting in a lightweight and supple feel ideal for apparel and delicate home textiles. Loomstate linen retains its natural, coarse texture with a stiffer hand, offering durability and a rustic aesthetic favored in upholstery and heavy-duty applications. The textural contrast between milled and loomstate linen significantly influences their tactile experience and suitability for different design purposes.

Durability and Longevity: Milled Linen vs Loomstate Linen

Milled linen undergoes a full finishing process that enhances fiber softness and reduces fabric shrinkage while maintaining high durability for long-term use. Loomstate linen, being untreated and in its natural state, retains maximum strength and resilience, offering superior longevity with minimal weakening from processing. Choosing between milled and loomstate linen depends on balancing the need for immediate comfort and softness against the desire for maximum fabric lifespan and toughness.

Care and Maintenance Requirements

Milled linen undergoes mechanical finishing processes that enhance softness and durability, making it easier to care for with less frequent ironing compared to loomstate linen. Loomstate linen retains its natural stiffness and requires more delicate handling, including gentle washing and careful ironing, to prevent damage and maintain its texture. Proper care for milled linen typically involves machine washing on a gentle cycle and tumble drying on low heat, while loomstate linen benefits from hand washing and air drying to preserve its raw finish.

Appearance and Color Retention

Milled linen features a softer, more textured appearance due to mechanical finishing processes that also enhance its durability and color retention. Loomstate linen, being untreated and in its natural state, retains a raw, crisp look with a matte finish but tends to fade more quickly over time when exposed to sunlight. The choice between milled and loomstate linen depends on desired aesthetics and long-term color stability.

Eco-friendliness and Sustainability Factors

Milled linen undergoes a gentle washing process that softens the fabric and removes impurities, reducing the need for harsh chemicals and minimizing environmental impact compared to conventional treatments. Loomstate linen is untreated and maintains its natural state, preserving all original fibers and promoting biodegradability and recyclability, which enhances its sustainability profile. Both types of linen offer eco-friendly advantages, with milled linen balancing comfort and reduced chemical use, while loomstate linen emphasizes raw material integrity and minimal processing.

Applications: Best Uses for Milled and Loomstate Linen

Milled linen, with its softer texture and enhanced durability, is ideal for upholstery, drapery, and high-end fashion garments requiring a refined finish. Loomstate linen retains its natural stiffness and durability, making it best suited for durable applications like industrial textiles, heavy-duty upholstery, and rustic home decor. Choosing between milled and loomstate linen depends on the desired texture and end-use requirements in interior design or apparel manufacturing.

Choosing the Right Linen: Milled or Loomstate?

Milled linen undergoes a finishing process that softens the fabric and increases durability, making it ideal for applications requiring a polished appearance and enhanced comfort. Loomstate linen, being untreated and unprocessed, retains its natural stiffness and texture, perfect for projects valuing raw linen's organic feel and breathability. Selecting between milled and loomstate linen depends on the desired balance of softness, strength, and aesthetic, tailoring to specific uses like upholstery, apparel, or home textiles.

Milled Linen vs Loomstate Linen Infographic

materialdif.com

materialdif.com