Wet spun linen offers superior fiber alignment and strength due to the fiber extraction process occurring in a water bath, resulting in smoother, softer, and more durable fabric ideal for high-quality textiles. Dry spun linen, produced without water immersion, tends to have a coarser texture and less uniform fiber composition, making it more suitable for rustic or casual linen products. Choosing between wet spun and dry spun linen depends on the desired fabric quality, texture, and end-use application.

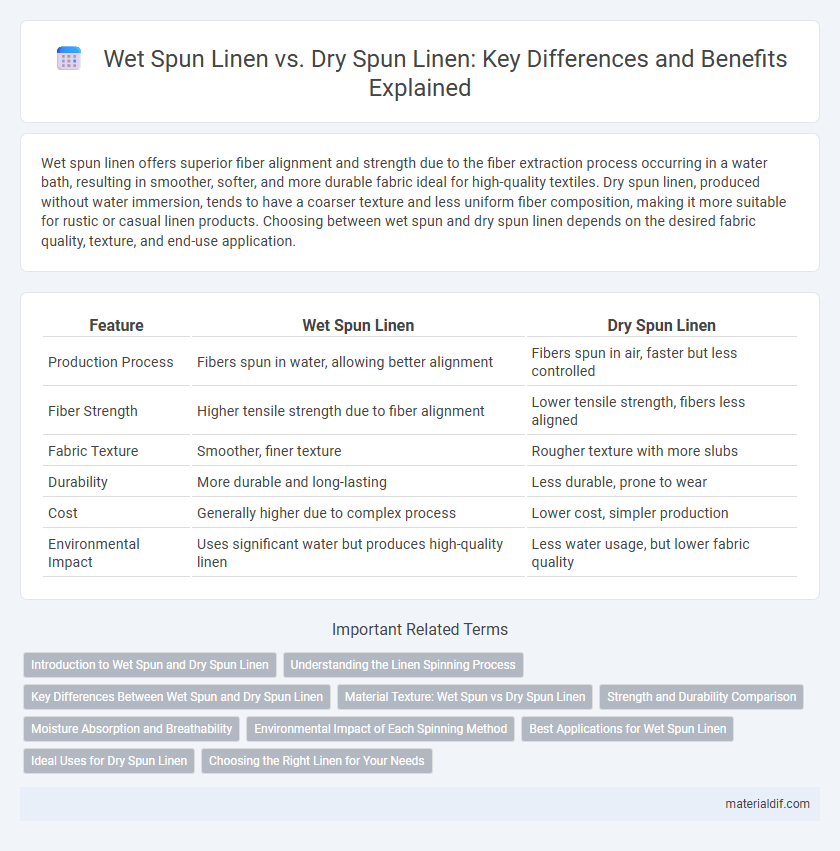

Table of Comparison

| Feature | Wet Spun Linen | Dry Spun Linen |

|---|---|---|

| Production Process | Fibers spun in water, allowing better alignment | Fibers spun in air, faster but less controlled |

| Fiber Strength | Higher tensile strength due to fiber alignment | Lower tensile strength, fibers less aligned |

| Fabric Texture | Smoother, finer texture | Rougher texture with more slubs |

| Durability | More durable and long-lasting | Less durable, prone to wear |

| Cost | Generally higher due to complex process | Lower cost, simpler production |

| Environmental Impact | Uses significant water but produces high-quality linen | Less water usage, but lower fabric quality |

Introduction to Wet Spun and Dry Spun Linen

Wet spun linen involves immersing flax fibers in water during the spinning process, resulting in stronger, smoother, and more uniform yarns ideal for high-quality textiles. Dry spun linen, by contrast, spins fibers without water, producing coarser, less even yarns that retain more natural texture and are typically used for rustic or heavier fabric applications. The choice between wet spun and dry spun linen directly influences the yarn's strength, texture, and end-use suitability in fashion or home textiles.

Understanding the Linen Spinning Process

Wet spun linen fibers are created by immersing flax fibers in water during the spinning process, resulting in stronger and finer yarns with a smoother texture ideal for high-quality textiles. Dry spun linen involves spinning fibers without water immersion, producing yarns with a coarser texture and greater elasticity, commonly used in more rustic or durable fabrics. Understanding these differences in spinning techniques helps in selecting the right linen type for specific textile applications based on strength, texture, and elasticity requirements.

Key Differences Between Wet Spun and Dry Spun Linen

Wet spun linen fibers undergo a process where flax fibers are immersed in water before spinning, resulting in stronger, finer, and more uniform threads ideal for high-quality textiles. Dry spun linen, produced without water immersion, yields coarser, less uniform fibers that retain more natural texture and are often used in rustic or casual fabric styles. The key differences lie in fiber strength, texture, and uniformity, influencing the final fabric's durability, softness, and appearance.

Material Texture: Wet Spun vs Dry Spun Linen

Wet spun linen fibers exhibit a smoother, more lustrous texture due to the immersion process, which aligns the fibers tightly and enhances their strength and softness. Dry spun linen, by contrast, retains a coarser, more textured surface as the fibers dry naturally without water immersion, resulting in a less uniform appearance and a slightly rougher feel. The difference in spinning techniques directly impacts the tactile quality and durability of linen fabrics, influencing their suitability for various textile applications.

Strength and Durability Comparison

Wet spun linen fibers exhibit higher tensile strength and improved durability compared to dry spun linen due to the fiber alignment and reduced tension during the wet spinning process. This method produces smoother, more uniform fibers that resist wear and tear better under repeated use. Dry spun linen, while still strong, tends to have a coarser texture and slightly lower durability because the fibers are spun without the lubricating effects of water.

Moisture Absorption and Breathability

Wet spun linen fibers exhibit superior moisture absorption and enhanced breathability compared to dry spun linen due to their longer, smoother fibers formed during the wet spinning process. The increased fiber length in wet spun linen creates a fabric structure with better air permeability and quicker moisture wicking capabilities, making it ideal for hot and humid climates. Dry spun linen, with shorter and coarser fibers, tends to have reduced moisture management and breathability, resulting in less comfort during prolonged wear.

Environmental Impact of Each Spinning Method

Wet spun linen requires significant water usage and chemical treatments, leading to higher environmental impact due to water pollution and resource consumption. Dry spun linen uses less water and fewer chemicals, resulting in reduced environmental footprint and lower energy consumption. Choosing dry spun linen supports more sustainable textile production with minimized ecological disturbance.

Best Applications for Wet Spun Linen

Wet spun linen fibers exhibit superior strength, smoothness, and uniformity compared to dry spun alternatives, making them ideal for high-end textiles such as luxury bedding, fine garments, and upscale upholstery. The wet spinning process aligns the flax fibers more closely, resulting in enhanced durability and a softer handfeel, which is preferred for products requiring both comfort and longevity. These qualities make wet spun linen especially suitable for premium applications where fabric aesthetics and performance are critical.

Ideal Uses for Dry Spun Linen

Dry spun linen, created through a process that involves drying the fibers before spinning, offers a smoother, finer texture ideal for high-quality apparel and delicate textiles. Its enhanced strength and softness make it perfect for lightweight garments, luxury bedding, and finely woven fabrics that require durability without sacrificing comfort. This method is especially suited for premium linen products where a refined finish and softness are paramount.

Choosing the Right Linen for Your Needs

Wet spun linen offers superior strength and smoothness due to the fiber's exposure to water during the spinning process, making it ideal for durable, high-quality textiles like fine bed linens and apparel. Dry spun linen, characterized by a rougher texture and less elasticity, suits applications where a rustic, textured appearance is preferred, such as upholstery, drapery, or artisanal crafts. Selecting between wet spun and dry spun linen depends on the desired fabric performance, texture, and end-use requirements.

Wet Spun Linen vs Dry Spun Linen Infographic

materialdif.com

materialdif.com