Open-end linen yarn offers a coarse texture with increased durability, making it ideal for sturdy pet products like beds and mats. Ring-spun linen yarn provides a smoother, finer finish that enhances comfort and softness for pet apparel and accessories. Choosing between the two depends on whether durability or comfort is the primary requirement for your linen pet items.

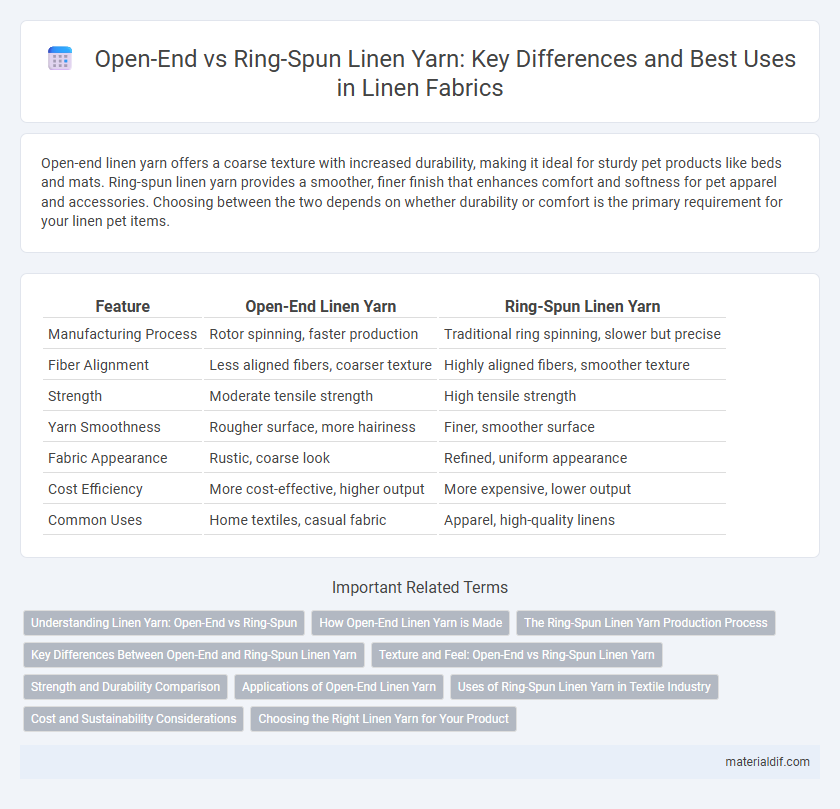

Table of Comparison

| Feature | Open-End Linen Yarn | Ring-Spun Linen Yarn |

|---|---|---|

| Manufacturing Process | Rotor spinning, faster production | Traditional ring spinning, slower but precise |

| Fiber Alignment | Less aligned fibers, coarser texture | Highly aligned fibers, smoother texture |

| Strength | Moderate tensile strength | High tensile strength |

| Yarn Smoothness | Rougher surface, more hairiness | Finer, smoother surface |

| Fabric Appearance | Rustic, coarse look | Refined, uniform appearance |

| Cost Efficiency | More cost-effective, higher output | More expensive, lower output |

| Common Uses | Home textiles, casual fabric | Apparel, high-quality linens |

Understanding Linen Yarn: Open-End vs Ring-Spun

Open-End linen yarn is produced through a rotor spinning process, resulting in a coarser texture and bulkier yarn that offers durability and lower production costs. In contrast, Ring-Spun linen yarn undergoes a continuous twisting method, creating finer, smoother, and stronger fibers ideal for high-quality, soft, and lightweight linen fabrics. Selecting between Open-End and Ring-Spun linen yarn impacts the final fabric's texture, strength, and price, with Open-End suited for robust applications and Ring-Spun preferred for premium textile products.

How Open-End Linen Yarn is Made

Open-end linen yarn is produced through a rotor spinning process where fibers are fed into a rapidly rotating rotor, causing them to be twisted into yarn without the need for a spindle. This method uses shorter fiber lengths and results in a coarser, less uniform yarn compared to ring-spun linen yarn, which is created by drawing and twisting longer fibers on a spindle. Open-end spinning offers higher production speeds and lower manufacturing costs, making it suitable for applications prioritizing durability over fine texture.

The Ring-Spun Linen Yarn Production Process

The ring-spun linen yarn production process involves twisting and thinning fibers to create a finer, stronger, and more durable yarn compared to open-end spinning. This method enhances the yarn's tensile strength and uniformity, resulting in smoother texture and higher-quality fabric. Ring-spun linen yarn is preferred for premium textile applications where softness and longevity are essential.

Key Differences Between Open-End and Ring-Spun Linen Yarn

Open-end linen yarn is produced through a rotor spinning process, resulting in a coarser texture and bulkier yarn ideal for durable fabrics, while ring-spun linen yarn undergoes a traditional spinning technique yielding finer, smoother, and stronger yarn suited for high-quality textiles. Open-end yarns typically have lower tensile strength and less uniformity compared to ring-spun yarns, which exhibit superior strength, smoothness, and consistent thickness. The choice between open-end and ring-spun linen yarns significantly impacts fabric texture, durability, and suitability for specific applications like upholstery versus premium apparel.

Texture and Feel: Open-End vs Ring-Spun Linen Yarn

Open-end linen yarn features a coarser texture with a more irregular surface, resulting in a rougher and thicker feel ideal for durable fabrics. Ring-spun linen yarn offers a smoother, finer texture due to its tightly twisted fibers, producing a softer and more luxurious hand. The choice between open-end and ring-spun affects the fabric's breathability, drape, and overall tactile sensation in linen textiles.

Strength and Durability Comparison

Open-end linen yarn exhibits a coarser texture with lower tensile strength compared to ring-spun linen yarn, which undergoes a finer spinning process resulting in superior fiber alignment and enhanced durability. Ring-spun linen yarn's tighter twist pattern increases its resistance to wear and tear, making it ideal for high-stress applications such as upholstery and heavy-duty textiles. The structural integrity of ring-spun yarn contributes to longer-lasting linens with better abrasion resistance than the more loosely structured open-end variety.

Applications of Open-End Linen Yarn

Open-end linen yarn is widely used in home textiles such as upholstery, curtains, and rugs due to its coarse texture and durability. Its cost-effectiveness and faster production process make it ideal for industrial fabrics requiring high strength and less fine finish. Open-end linen yarn is also favored in casual apparel and accessories where a rustic, natural aesthetic is desired.

Uses of Ring-Spun Linen Yarn in Textile Industry

Ring-spun linen yarn is favored in the textile industry for producing high-quality fabrics that require enhanced strength, smoothness, and durability, making it ideal for garments, home textiles, and upholstery. Its fine, tightly twisted fibers offer a softer hand feel and improved resistance to wear compared to open-end linen yarn, which suits premium clothing lines and delicate fabric blends. The consistent texture and superior tensile properties of ring-spun linen yarn enable manufacturers to achieve refined finishing and vibrant dye uptake in luxury textile products.

Cost and Sustainability Considerations

Open-end linen yarn production typically costs less due to faster spinning speeds and lower labor requirements compared to ring-spun linen yarn, which involves a more intricate process producing finer, stronger yarns. In terms of sustainability, open-end spinning consumes less energy and results in less fiber waste, making it a more eco-friendly option, while ring-spun linen yarn often requires more processing steps that increase resource consumption. Brands prioritizing cost-efficiency and environmental impact frequently opt for open-end linen yarn, whereas premium products favor the durability and quality of ring-spun linen despite higher environmental and monetary costs.

Choosing the Right Linen Yarn for Your Product

Open-end linen yarn offers coarser texture and higher productivity, ideal for durable, rustic textiles, while ring-spun linen yarn provides finer, smoother fibers suited for premium, soft fabric applications. Selecting the right linen yarn depends on the desired fabric strength, softness, and end-use, with open-end yarn favoring cost-efficiency and ring-spun yarn supporting luxury and comfort. Understanding these distinctions ensures optimal performance and quality in linen-based products.

Open-End Linen Yarn vs Ring-Spun Linen Yarn Infographic

materialdif.com

materialdif.com