European flax produces higher-quality linen fibers due to its cooler climate, which results in finer and stronger threads ideal for luxury textiles. Asian flax, grown in warmer regions, tends to yield coarser fibers better suited for heavier fabrics and industrial applications. The distinct environmental conditions influence fiber length, strength, and texture, making European flax preferable for premium linen products.

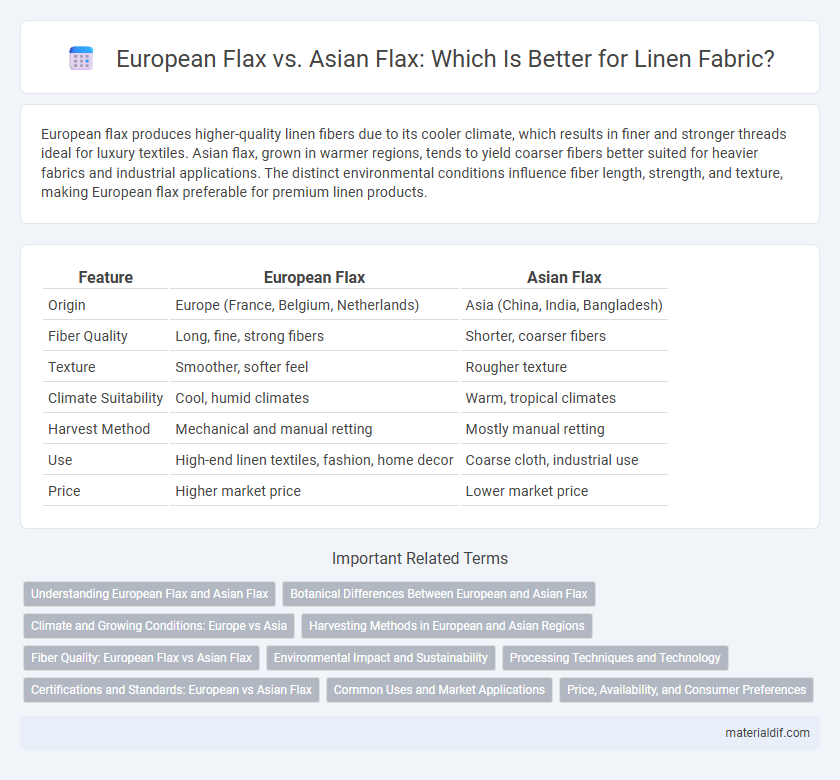

Table of Comparison

| Feature | European Flax | Asian Flax |

|---|---|---|

| Origin | Europe (France, Belgium, Netherlands) | Asia (China, India, Bangladesh) |

| Fiber Quality | Long, fine, strong fibers | Shorter, coarser fibers |

| Texture | Smoother, softer feel | Rougher texture |

| Climate Suitability | Cool, humid climates | Warm, tropical climates |

| Harvest Method | Mechanical and manual retting | Mostly manual retting |

| Use | High-end linen textiles, fashion, home decor | Coarse cloth, industrial use |

| Price | Higher market price | Lower market price |

Understanding European Flax and Asian Flax

European flax, predominantly grown in countries like France, Belgium, and the Netherlands, is renowned for its long fibers and superior quality, making it a preferred source for high-end linen production. Asian flax, mainly cultivated in China and India, offers shorter fibers with a coarser texture but is valued for its versatility and cost-effectiveness in large-scale textile manufacturing. Understanding the regional differences between European and Asian flax is crucial for selecting the appropriate fiber based on fabric texture, durability, and end-use applications.

Botanical Differences Between European and Asian Flax

European flax (Linum usitatissimum) typically features taller, sturdier stalks with longer fibers that produce finer, high-quality linen, while Asian flax varieties often exhibit shorter plants with coarser fibers suitable for heavier textile applications. The botanical difference lies in the fiber cell structure; European flax has a higher cellulose content and thinner cell walls, enhancing fiber fineness and strength. European flax thrives in temperate climates with well-drained soils, contrasting with Asian flax adapted to diverse environments, influencing their growth patterns and fiber characteristics.

Climate and Growing Conditions: Europe vs Asia

European flax thrives in the cool, temperate climates of countries such as Belgium and France, where consistent rainfall and rich, well-drained soils produce long, strong fibers ideal for high-quality linen. In contrast, Asian flax, primarily grown in regions like China and India, faces warmer, more humid conditions that often result in shorter fibers with different textile properties. These climatic differences significantly influence the texture, durability, and application of linen fabrics sourced from each region.

Harvesting Methods in European and Asian Regions

European flax harvesting typically involves mechanical techniques, such as specialized combines that streamline stem cutting and retting, enhancing fiber quality and uniformity. In contrast, Asian flax harvesting often relies on manual methods, including hand-pulling and traditional retting processes, which can result in more variable fiber textures and lengths. These regional differences impact the overall fiber strength and suitability for various textile applications.

Fiber Quality: European Flax vs Asian Flax

European flax is renowned for its long, fine, and strong fibers, making it the preferred choice in high-quality linen production for luxury textiles and fashion. Asian flax, while more abundant and cost-effective, generally produces shorter and coarser fibers, which are often used in industrial applications or blended textiles. The superior fiber quality of European flax results in smoother, more durable linen with a finer texture and greater tensile strength.

Environmental Impact and Sustainability

European flax cultivation generally demonstrates a lower environmental impact compared to Asian flax due to its reliance on rain-fed agriculture, reducing water consumption significantly. The shorter processing cycles and stricter EU regulations foster higher sustainability standards, including minimal pesticide use and enhanced soil health. Conversely, Asian flax often involves intensive irrigation and chemical inputs, increasing its ecological footprint and challenging long-term sustainability efforts.

Processing Techniques and Technology

European flax is renowned for its traditional retting process, which employs dew retting that naturally breaks down pectin, preserving fiber strength and resulting in premium-quality linen with superior fineness and durability. In contrast, Asian flax often utilizes water retting methods combined with advanced mechanical decortication technologies, accelerating fiber extraction but sometimes compromising fiber softness and consistency. European processors frequently incorporate eco-friendly enzymatic treatments, enhancing fiber purity without harsh chemicals, whereas Asian facilities prioritize high-throughput automation to meet mass production demands.

Certifications and Standards: European vs Asian Flax

European flax often adheres to stringent certifications such as OEKO-TEX Standard 100 and GOTS (Global Organic Textile Standard), ensuring high-quality, sustainable, and chemical-free production processes. Asian flax, while expanding in quality, frequently meets regional standards like China's GB standards or Japan's JIS, which may not always align with the comprehensive environmental and social criteria seen in European certifications. Differences in certifications impact market acceptance, with European flax preferred for premium textile markets demanding verified eco-friendly and ethical credentials.

Common Uses and Market Applications

European flax, primarily grown in countries like France, Belgium, and the Netherlands, is renowned for its high-quality fiber used predominantly in premium textiles and luxury linen products. Asian flax, cultivated mainly in China and India, typically produces coarser fibers suited for industrial uses such as ropes, composites, and insulation materials. The European flax market emphasizes fashion and home textiles, while Asian flax is more focused on large-scale industrial and commercial applications.

Price, Availability, and Consumer Preferences

European flax, particularly sourced from France and Belgium, commands higher prices due to its premium quality and limited availability compared to Asian flax, mainly from China and India. European flax fibers are favored by consumers seeking superior softness, durability, and eco-friendly production, resulting in strong demand despite cost. Asian flax, being more abundant and economically priced, appeals to budget-conscious buyers but often lacks the refined texture and consistency prized in luxury linen markets.

European Flax vs Asian Flax Infographic

materialdif.com

materialdif.com