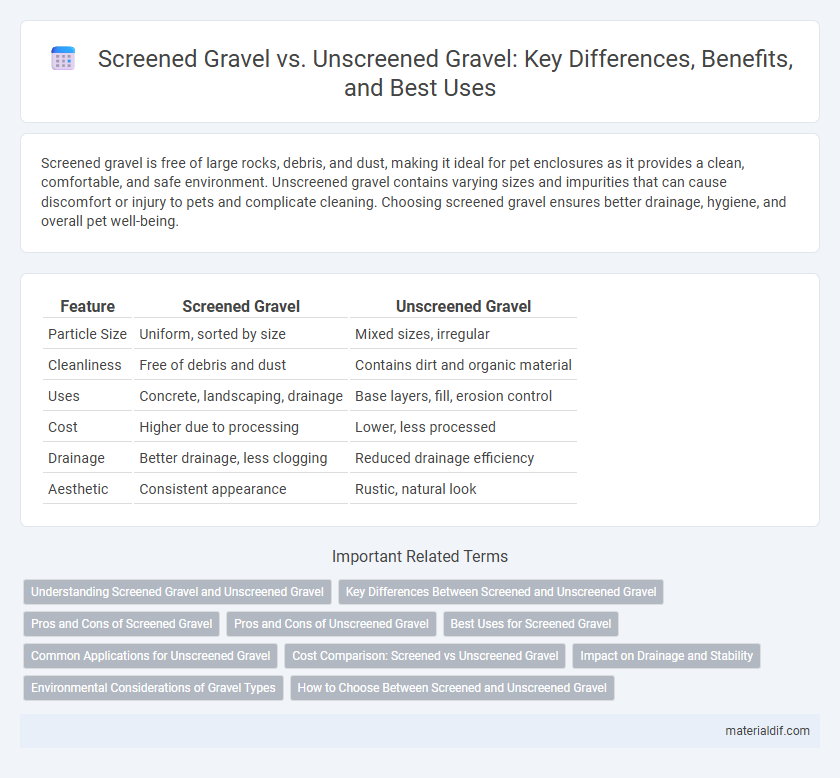

Screened gravel is free of large rocks, debris, and dust, making it ideal for pet enclosures as it provides a clean, comfortable, and safe environment. Unscreened gravel contains varying sizes and impurities that can cause discomfort or injury to pets and complicate cleaning. Choosing screened gravel ensures better drainage, hygiene, and overall pet well-being.

Table of Comparison

| Feature | Screened Gravel | Unscreened Gravel |

|---|---|---|

| Particle Size | Uniform, sorted by size | Mixed sizes, irregular |

| Cleanliness | Free of debris and dust | Contains dirt and organic material |

| Uses | Concrete, landscaping, drainage | Base layers, fill, erosion control |

| Cost | Higher due to processing | Lower, less processed |

| Drainage | Better drainage, less clogging | Reduced drainage efficiency |

| Aesthetic | Consistent appearance | Rustic, natural look |

Understanding Screened Gravel and Unscreened Gravel

Screened gravel consists of carefully sifted particles, removing fine materials and debris to ensure uniform size and improve drainage, making it ideal for construction and landscaping projects. Unscreened gravel contains a mix of fine and coarse materials, including dirt and smaller particles, which can compact over time and affect stability. Choosing screened gravel provides better consistency and performance, while unscreened gravel is typically more affordable but less suitable for applications requiring precise material quality.

Key Differences Between Screened and Unscreened Gravel

Screened gravel consists of uniformly sized particles separated by a sieve, resulting in consistent texture and fewer impurities, making it ideal for precise construction and landscaping applications. Unscreened gravel contains a mix of variously sized stones and fines, providing better compaction and drainage but less uniformity, often used in foundational or base layers. The particle size consistency and cleanliness distinguish screened gravel for decorative use, whereas unscreened gravel suits structural and drainage needs.

Pros and Cons of Screened Gravel

Screened gravel offers uniform particle size, improving drainage and compaction for construction and landscaping projects, making it ideal for pathways and concrete mixing. Its consistency reduces the risk of settling and enhances aesthetic appeal, but the screening process can increase cost and limit availability compared to unscreened gravel. While screened gravel provides better quality control, it may lack the natural appearance and texture variety found in unscreened gravel.

Pros and Cons of Unscreened Gravel

Unscreened gravel contains a mix of different particle sizes, including fine soil and smaller stones, which helps improve compaction and stability in construction projects such as road bases and drainage systems. Its cost-effectiveness is a major advantage, as it is typically less expensive than screened gravel due to minimal processing. However, the presence of fine materials can reduce permeability and may lead to poor drainage, making unscreened gravel less ideal for applications requiring high water flow.

Best Uses for Screened Gravel

Screened gravel, characterized by uniform particle size and free from debris, is ideal for applications requiring a smooth, compact surface such as driveways, walkways, and concrete mixes. Its consistent texture enhances drainage and provides stability for foundations and landscaping projects. This type of gravel is preferred where precise composition and clean material improve both aesthetics and functional performance.

Common Applications for Unscreened Gravel

Unscreened gravel is commonly used in construction projects requiring strong foundational support, such as road beds, drainage systems, and retaining wall bases due to its larger, mixed particle sizes that provide excellent stability and compaction. It is also favored for landscaping applications like pathways and driveways where natural texture and durability are important. The presence of fines and varying gravel sizes in unscreened materials enhances interlocking properties, making it ideal for load-bearing surfaces.

Cost Comparison: Screened vs Unscreened Gravel

Screened gravel generally costs more than unscreened gravel due to the additional processing involved in removing fines and debris, which results in a cleaner, more uniform material. Unscreened gravel is typically cheaper because it is less processed and contains a mix of particle sizes, including dirt and smaller fragments. The price difference varies by region and supplier but can impact project budgets significantly, making unscreened gravel a cost-effective option for less critical applications.

Impact on Drainage and Stability

Screened gravel offers enhanced drainage and stability by removing fine particles that clog pores, allowing water to flow freely and reducing the risk of waterlogging. Unscreened gravel contains a mix of fines and larger particles, which can impair drainage and lead to uneven settling or instability in construction projects. Optimizing the grain size distribution through screening improves compaction, load-bearing capacity, and long-term durability of gravel-based foundations.

Environmental Considerations of Gravel Types

Screened gravel, free from fines and impurities, reduces sediment runoff and soil erosion in construction and landscaping, minimizing environmental impact. Unscreened gravel contains natural soil and clay particles, which can increase turbidity in nearby water bodies and contribute to habitat disruption. Choosing screened gravel supports better water quality management and promotes sustainable land use practices.

How to Choose Between Screened and Unscreened Gravel

Choosing between screened and unscreened gravel depends on the specific project requirements and desired outcome. Screened gravel, free from fine particles and debris, ensures uniform particle size ideal for concrete mixes, drainage systems, or decorative surfaces. Unscreened gravel retains natural fines and various sizes, providing better compaction and stability for base layers, driveways, or erosion control.

Screened Gravel vs Unscreened Gravel Infographic

materialdif.com

materialdif.com