Bank run gravel consists of natural, unprocessed aggregates collected directly from riverbeds or banks, offering a mix of various-sized materials with a rough texture ideal for drainage and foundational support. Processed gravel undergoes crushing, screening, and washing to produce uniform, clean particles suitable for precise construction needs such as concrete production and asphalt mixtures. Choosing between bank run and processed gravel depends on project specifications, with bank run gravel favored for cost-effective base layers and processed gravel preferred for strength and consistency in structural applications.

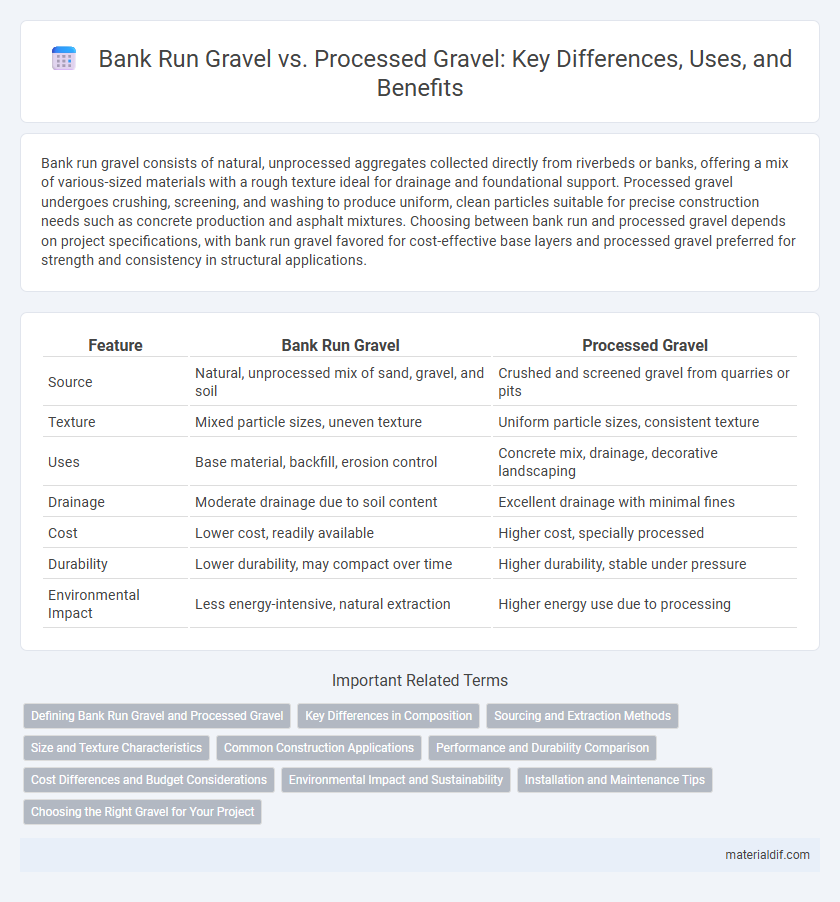

Table of Comparison

| Feature | Bank Run Gravel | Processed Gravel |

|---|---|---|

| Source | Natural, unprocessed mix of sand, gravel, and soil | Crushed and screened gravel from quarries or pits |

| Texture | Mixed particle sizes, uneven texture | Uniform particle sizes, consistent texture |

| Uses | Base material, backfill, erosion control | Concrete mix, drainage, decorative landscaping |

| Drainage | Moderate drainage due to soil content | Excellent drainage with minimal fines |

| Cost | Lower cost, readily available | Higher cost, specially processed |

| Durability | Lower durability, may compact over time | Higher durability, stable under pressure |

| Environmental Impact | Less energy-intensive, natural extraction | Higher energy use due to processing |

Defining Bank Run Gravel and Processed Gravel

Bank run gravel consists of naturally occurring, unprocessed aggregates gathered directly from riverbanks or gravel pits, containing a mix of variously sized particles including sand, silt, and clay. Processed gravel undergoes mechanical crushing, sorting, and washing to achieve uniform particle sizes and remove impurities, making it suitable for specific construction applications. Understanding the distinction between bank run and processed gravel is crucial for selecting the appropriate material based on project requirements and soil stability.

Key Differences in Composition

Bank Run Gravel consists of natural, unprocessed materials directly excavated from riverbeds or quarries, containing a mix of sand, clay, silt, and various sized stones. Processed Gravel undergoes crushing, screening, and washing to remove impurities, resulting in a more uniform particle size distribution and higher purity. The key difference in composition lies in Bank Run Gravel's heterogeneous mixture versus the refined, consistent particle composition of Processed Gravel.

Sourcing and Extraction Methods

Bank run gravel is naturally extracted directly from riverbeds or gravel pits without extensive processing, preserving its mixed particle sizes and organic materials. Processed gravel undergoes screening, washing, and sorting to remove impurities and ensure uniform size and quality for construction standards. Sourcing bank run gravel involves minimal equipment and environmental disturbance, whereas processed gravel extraction requires advanced machinery and more intensive separation techniques.

Size and Texture Characteristics

Bank run gravel consists of naturally deposited materials with varied sizes and a rough, uneven texture, providing excellent drainage and stability for construction projects. Processed gravel is mechanically sorted and crushed to uniform sizes with smoother edges, ensuring consistent compaction and enhanced structural integrity in concrete and paving applications. The choice between bank run and processed gravel depends on specific project requirements for size uniformity and surface texture.

Common Construction Applications

Bank run gravel consists of naturally occurring, unwashed, and unsorted materials typically used for foundational fill and drainage layers in construction projects. Processed gravel undergoes washing, sorting, and crushing, making it suitable for more precise applications like concrete mix, road base, and landscaping top layers. Both types are essential in construction, but processed gravel offers enhanced durability and uniformity critical for structural stability.

Performance and Durability Comparison

Bank run gravel, sourced directly from natural deposits, contains a mix of sizes and materials, which often results in lower consistency in performance and durability compared to processed gravel. Processed gravel undergoes crushing and screening to achieve uniform particle size and remove impurities, enhancing its load-bearing capacity and resistance to weathering. This consistency makes processed gravel more suitable for construction applications requiring long-lasting stability and superior strength.

Cost Differences and Budget Considerations

Bank run gravel, sourced directly from natural deposits without additional processing, typically offers lower upfront costs compared to processed gravel due to minimal handling and transportation expenses. Processed gravel undergoes crushing and screening to achieve specific size and quality standards, increasing both production costs and market price. Budget considerations should weigh the cost-effectiveness of bank run gravel for large-scale projects against the enhanced durability and uniformity that processed gravel provides in precision applications.

Environmental Impact and Sustainability

Bank run gravel, sourced directly from natural riverbeds, typically has a lower environmental impact due to minimal processing and reduced energy consumption, promoting sustainability by preserving resource integrity. Processed gravel, involving crushing and screening, consumes more energy and generates emissions, which may increase its environmental footprint but offers consistent particle size beneficial for construction durability. Choosing bank run gravel supports eco-friendly projects by minimizing carbon emissions and habitat disruption compared to heavily processed alternatives.

Installation and Maintenance Tips

Bank Run gravel features a natural mix of sand, clay, and stones ideal for base layers, providing excellent compaction and stability during installation, which reduces shifting over time. Processed gravel consists of uniformly sized crushed stones that facilitate better drainage and create a smooth surface, making it easier to maintain and less prone to weed growth. For optimal longevity, compact Bank Run gravel thoroughly during installation and periodically regrade Processed gravel to prevent surface erosion and maintain evenness.

Choosing the Right Gravel for Your Project

Bank run gravel consists of naturally mixed stones, sand, and silt, making it ideal for projects requiring excellent drainage and natural compaction, such as driveways and base layers. Processed gravel is mechanically sorted and washed, offering consistent size and cleanliness, which suits decorative landscaping, concrete mixes, and applications needing precise grading. Selecting the right gravel depends on project requirements for drainage, compaction, appearance, and structural stability to ensure optimal performance and longevity.

Bank Run Gravel vs Processed Gravel Infographic

materialdif.com

materialdif.com