Recycled gravel offers an eco-friendly alternative by repurposing crushed concrete and asphalt, reducing waste and lowering environmental impact compared to quarry gravel, which is extracted directly from natural stone deposits. Quarry gravel provides consistent quality and strength, making it ideal for structural projects, while recycled gravel tends to be more affordable but may have variable properties depending on the source material. Choosing between recycled and quarry gravel depends on project requirements, budget, and sustainability goals.

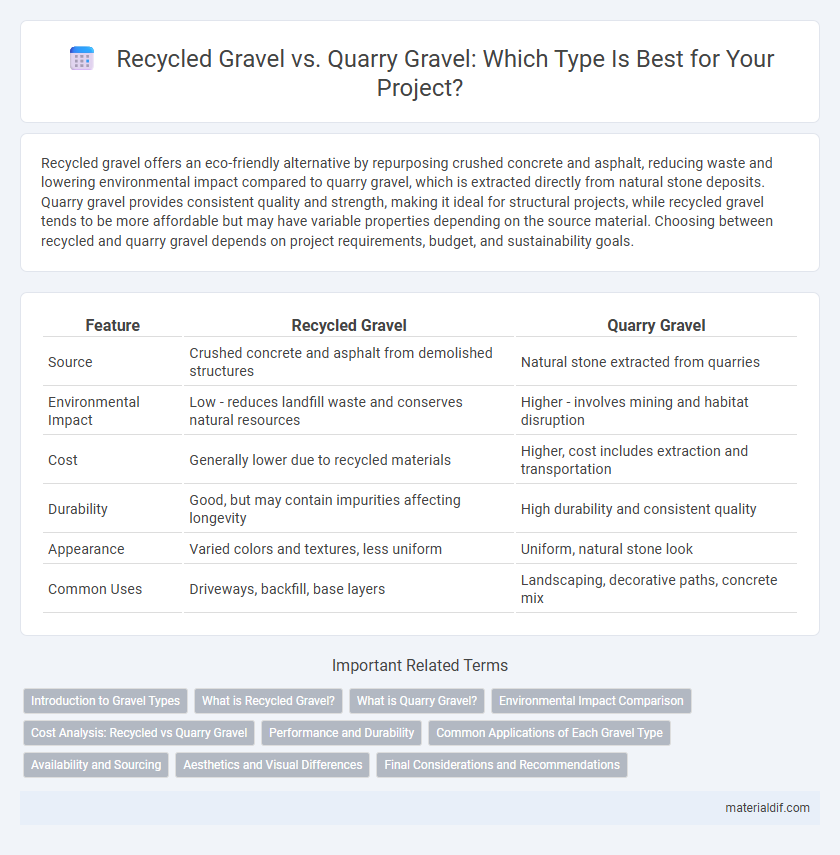

Table of Comparison

| Feature | Recycled Gravel | Quarry Gravel |

|---|---|---|

| Source | Crushed concrete and asphalt from demolished structures | Natural stone extracted from quarries |

| Environmental Impact | Low - reduces landfill waste and conserves natural resources | Higher - involves mining and habitat disruption |

| Cost | Generally lower due to recycled materials | Higher, cost includes extraction and transportation |

| Durability | Good, but may contain impurities affecting longevity | High durability and consistent quality |

| Appearance | Varied colors and textures, less uniform | Uniform, natural stone look |

| Common Uses | Driveways, backfill, base layers | Landscaping, decorative paths, concrete mix |

Introduction to Gravel Types

Recycled gravel consists of crushed concrete, asphalt, and other construction debris repurposed for various landscaping and construction projects. Quarry gravel, extracted directly from natural rock formations, typically offers more consistent size and mineral composition. Both types provide effective drainage and stability, but recycled gravel promotes sustainability by reducing waste and conserving natural resources.

What is Recycled Gravel?

Recycled gravel is made from crushed concrete, asphalt, and other construction debris, offering an eco-friendly alternative to natural quarry gravel. Its composition provides excellent drainage and compaction properties, making it ideal for driveways, landscaping, and road base applications. Compared to quarry gravel, recycled gravel reduces landfill waste and conserves natural resources while maintaining structural integrity for various construction projects.

What is Quarry Gravel?

Quarry gravel is natural stone material extracted directly from rock quarries, consisting of angular, durable particles ideal for construction and landscaping. Unlike recycled gravel, which is made from crushed concrete or asphalt, quarry gravel offers consistent composition and strength due to its virgin rock origin. Its high density and mineral composition provide superior drainage and stability in road bases, driveways, and drainage systems.

Environmental Impact Comparison

Recycled gravel reduces landfill waste and lowers the demand for natural resources by repurposing construction debris, significantly decreasing environmental degradation compared to quarry gravel. Quarry gravel extraction leads to habitat disruption, increased energy consumption, and higher carbon emissions due to mining and transportation activities. Choosing recycled gravel supports sustainable construction practices by minimizing ecological footprints and conserving natural landscapes.

Cost Analysis: Recycled vs Quarry Gravel

Recycled gravel typically costs 20-40% less than quarry gravel due to lower material and transportation expenses, making it a budget-friendly option for construction projects. Quarry gravel offers consistent size and quality, which may reduce long-term maintenance costs despite higher initial prices. Cost analysis should also consider factors like project scale, environmental impact fees, and availability when choosing between recycled and quarry gravel.

Performance and Durability

Recycled gravel offers sustainable benefits but may exhibit variable performance due to mixed material composition, potentially leading to lower durability compared to quarry gravel. Quarry gravel provides consistent particle size and mineral quality, resulting in superior strength and long-term resilience for construction and landscaping applications. Choosing quarry gravel ensures enhanced stability and reduced maintenance costs over recycled alternatives.

Common Applications of Each Gravel Type

Recycled gravel is frequently used in driveway bases, landscaping projects, and as a cost-effective material for erosion control due to its affordability and eco-friendly nature. Quarry gravel, known for its consistent size and durability, is preferred in concrete production, road construction, and heavy-duty drainage systems. Each gravel type offers unique benefits tailored to specific construction and landscaping needs, optimizing performance and sustainability in varying applications.

Availability and Sourcing

Recycled gravel is widely available in urban areas due to its production from demolished concrete and asphalt, making it a sustainable and cost-effective option. Quarry gravel, sourced directly from natural deposits, often requires extraction permits and is subject to location-dependent availability and transportation costs. Sourcing recycled gravel reduces environmental impact by repurposing existing materials, while quarry gravel offers consistent grading and mineral composition for construction needs.

Aesthetics and Visual Differences

Recycled gravel often exhibits varied coloration and irregular shapes due to its composition from crushed concrete, offering a rustic, eclectic aesthetic perfect for informal landscaping. Quarry gravel features consistent size and natural hues, such as grays and earth tones, creating a uniform and polished appearance suited for formal designs. The distinct textures and color variations between recycled and quarry gravel significantly influence the visual impact and style of outdoor spaces.

Final Considerations and Recommendations

Recycled gravel offers sustainable benefits by reducing landfill waste and conserving natural resources, but it may have variable composition affecting durability and drainage. Quarry gravel provides consistent quality and strength, making it ideal for structural applications requiring long-term stability. For projects prioritizing environmental impact, recycled gravel is recommended, whereas quarry gravel suits critical construction needs where reliability is essential.

Recycled gravel vs Quarry gravel Infographic

materialdif.com

materialdif.com