Erosion control gravel is specifically designed to stabilize soil, reduce runoff, and prevent soil degradation, featuring angular and heavier particles that lock together effectively. General fill gravel serves primarily as a base material for construction projects, offering good compaction and drainage but lacking the enhanced soil-binding properties of erosion control gravel. Choosing the right type depends on project needs, with erosion control gravel preferred for slopes and landscaping, while general fill gravel is ideal for foundational support and bulk filling.

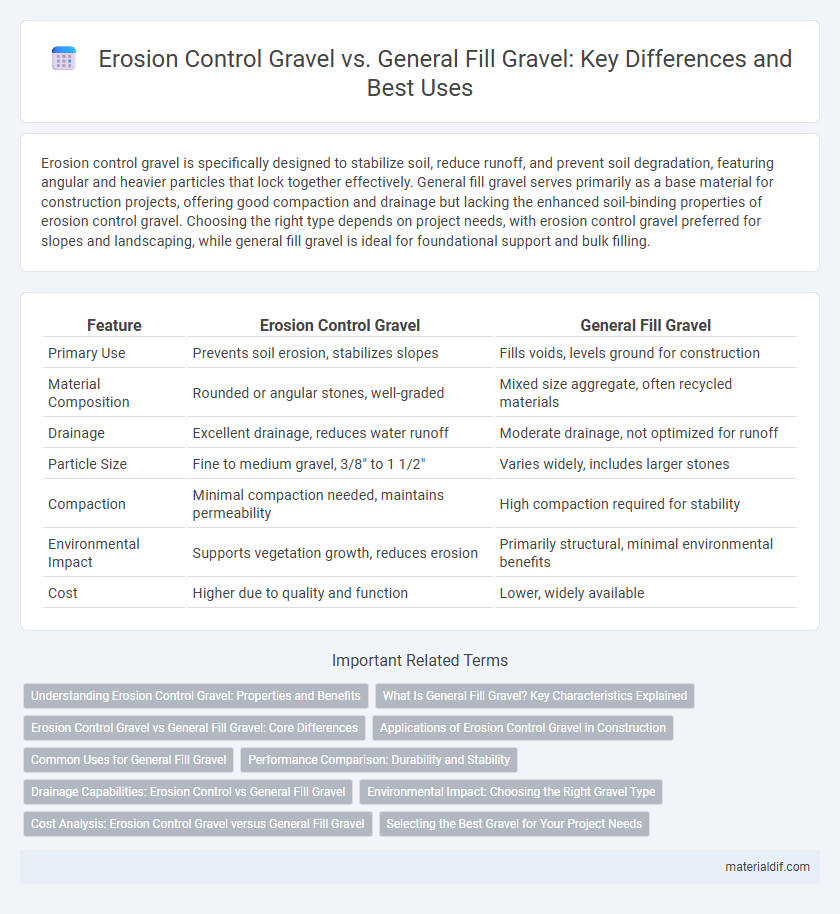

Table of Comparison

| Feature | Erosion Control Gravel | General Fill Gravel |

|---|---|---|

| Primary Use | Prevents soil erosion, stabilizes slopes | Fills voids, levels ground for construction |

| Material Composition | Rounded or angular stones, well-graded | Mixed size aggregate, often recycled materials |

| Drainage | Excellent drainage, reduces water runoff | Moderate drainage, not optimized for runoff |

| Particle Size | Fine to medium gravel, 3/8" to 1 1/2" | Varies widely, includes larger stones |

| Compaction | Minimal compaction needed, maintains permeability | High compaction required for stability |

| Environmental Impact | Supports vegetation growth, reduces erosion | Primarily structural, minimal environmental benefits |

| Cost | Higher due to quality and function | Lower, widely available |

Understanding Erosion Control Gravel: Properties and Benefits

Erosion control gravel features angular, durable particles designed to resist water flow and prevent soil displacement, unlike general fill gravel which primarily provides basic structural support. Its high permeability facilitates effective drainage, reducing runoff and soil erosion in slopes and embankments. Using erosion control gravel enhances landscape stability and longevity by maintaining soil integrity under varying environmental conditions.

What Is General Fill Gravel? Key Characteristics Explained

General fill gravel consists of a mixture of coarse and fine aggregates primarily used to fill large voids or level surfaces in construction projects. Its key characteristics include high compaction ability, good drainage properties, and affordability, making it ideal for base layers beneath roads, foundations, or slabs. Unlike erosion control gravel, general fill gravel prioritizes structural support over surface water flow management.

Erosion Control Gravel vs General Fill Gravel: Core Differences

Erosion control gravel features angular, durable rocks designed to prevent soil displacement and manage water runoff effectively, while general fill gravel consists of mixed-sized, rounded stones intended primarily for bulk filling and leveling. Erosion control gravel's composition and structure provide superior resistance to water flow and soil erosion, making it ideal for stabilizing slopes, drainage areas, and embankments. In contrast, general fill gravel lacks specific erosion prevention properties and is commonly used for foundational support and backfill in construction projects.

Applications of Erosion Control Gravel in Construction

Erosion control gravel is specifically designed with angular, durable particles that promote water drainage and soil stabilization, making it ideal for use in slope protection, drainage systems, and erosion-prone areas in construction projects. Unlike general fill gravel, which primarily serves as a base material or for leveling, erosion control gravel prevents sediment displacement and supports vegetation growth on embankments and retention walls. Its application in constructing retaining walls, culverts, and channel linings effectively reduces soil erosion while maintaining structural integrity and environmental sustainability.

Common Uses for General Fill Gravel

General fill gravel is primarily used to stabilize construction sites, serving as a foundational layer for roads, driveways, and building slabs. Unlike erosion control gravel, which is designed to prevent soil displacement, general fill gravel provides bulk support and improves drainage by allowing water to pass through. Its common applications include backfilling trenches, leveling uneven ground, and supporting heavy structures in residential and commercial projects.

Performance Comparison: Durability and Stability

Erosion control gravel is engineered for superior durability with angular, interlocking particles that reduce soil displacement and enhance water drainage, making it ideal for stabilizing slopes and preventing washouts. General fill gravel consists of more rounded, less cohesive particles suited mainly for volume filling but offers lower stability and susceptibility to shifting under pressure. Performance comparisons highlight erosion control gravel's enhanced longevity and resistance to environmental stresses, outperforming general fill in maintaining structural integrity over time.

Drainage Capabilities: Erosion Control vs General Fill Gravel

Erosion control gravel features angular, durable particles that create voids for superior water flow, effectively minimizing soil displacement and runoff. General fill gravel typically contains more rounded stones, resulting in lower permeability and reduced drainage capacity. Choosing erosion control gravel enhances drainage efficiency and soil stability, crucial for preventing erosion on slopes and embankments.

Environmental Impact: Choosing the Right Gravel Type

Erosion control gravel is specifically designed with angular, durable stones that reduce soil displacement and runoff, making it effective for stabilizing slopes, riverbanks, and construction sites while minimizing sediment pollution in nearby waterways. General fill gravel, often composed of rounded, less compact materials, tends to allow more water flow and soil movement, potentially increasing erosion and negatively impacting local ecosystems. Selecting erosion control gravel supports sustainable land management by enhancing vegetation growth and protecting natural habitats from degradation caused by soil erosion.

Cost Analysis: Erosion Control Gravel versus General Fill Gravel

Erosion control gravel typically costs more than general fill gravel due to its specialized composition designed to prevent soil displacement and water runoff. General fill gravel, often composed of cheaper, mixed aggregates, is primarily used for basic ground stabilization and may require more frequent replacement or additional measures to manage erosion. Investing in erosion control gravel can reduce long-term maintenance expenses despite higher initial costs by minimizing soil loss and infrastructure damage.

Selecting the Best Gravel for Your Project Needs

Erosion control gravel is specifically designed with angular, coarse particles to stabilize soil and prevent runoff, making it ideal for landscaping and drainage projects. General fill gravel consists of a mix of particle sizes and shapes, primarily used for base material and structural support in construction. Choosing the best gravel depends on project goals: erosion control gravel for slope stabilization and water flow management, while general fill gravel suits foundational and backfill applications.

Erosion Control Gravel vs General Fill Gravel Infographic

materialdif.com

materialdif.com