Gravel compaction increases stability and load-bearing capacity by reducing air gaps between particles, making surfaces firmer and more durable for driveways and pathways. Loose gravel, while easier to spread and drain, tends to shift under pressure, causing uneven surfaces and requiring frequent maintenance. Choosing compacted gravel enhances longevity and safety, especially in high-traffic areas where solid footing is essential.

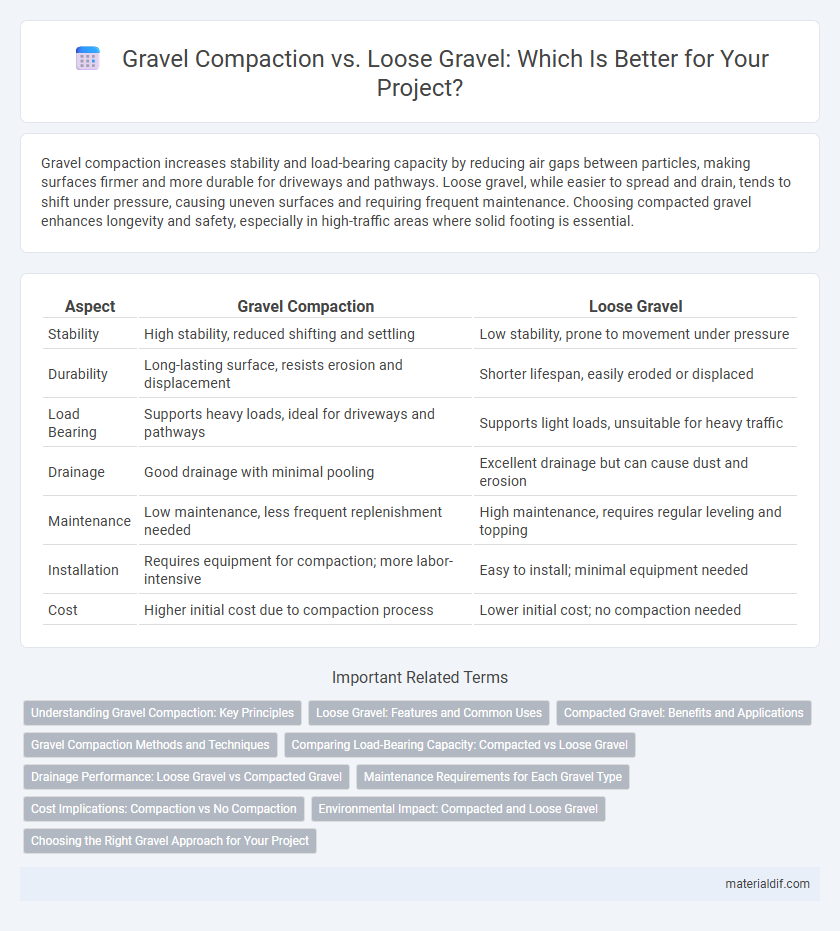

Table of Comparison

| Aspect | Gravel Compaction | Loose Gravel |

|---|---|---|

| Stability | High stability, reduced shifting and settling | Low stability, prone to movement under pressure |

| Durability | Long-lasting surface, resists erosion and displacement | Shorter lifespan, easily eroded or displaced |

| Load Bearing | Supports heavy loads, ideal for driveways and pathways | Supports light loads, unsuitable for heavy traffic |

| Drainage | Good drainage with minimal pooling | Excellent drainage but can cause dust and erosion |

| Maintenance | Low maintenance, less frequent replenishment needed | High maintenance, requires regular leveling and topping |

| Installation | Requires equipment for compaction; more labor-intensive | Easy to install; minimal equipment needed |

| Cost | Higher initial cost due to compaction process | Lower initial cost; no compaction needed |

Understanding Gravel Compaction: Key Principles

Gravel compaction increases density by reducing air spaces between particles, enhancing load-bearing capacity and stability for construction projects and roadways. Proper compaction prevents shifting and settling, which can lead to uneven surfaces and structural damage. Understanding factors such as moisture content, gravel size, and compaction equipment is crucial to achieving optimal gravel compaction and long-term durability.

Loose Gravel: Features and Common Uses

Loose gravel consists of small, unconsolidated rock fragments that provide excellent drainage and flexibility for various landscaping and construction projects. Its porous nature makes it ideal for driveways, pathways, and garden beds where water permeability is essential. Common uses include decorative ground cover, erosion control, and temporary road surfaces due to its ease of installation and cost-effectiveness.

Compacted Gravel: Benefits and Applications

Compacted gravel provides a stable and durable surface ideal for driveways, pathways, and foundations, reducing erosion and minimizing maintenance. Its tightly packed particles improve load-bearing capacity and drainage, preventing shifting and surface deformation under heavy traffic. Applications include road base layers, patio flooring, and erosion control in landscaping projects, where longevity and stability are critical.

Gravel Compaction Methods and Techniques

Gravel compaction techniques such as plate compactors, roller compactors, and vibrating compactors enhance stability by increasing gravel density and reducing air gaps, creating a solid, durable surface. Proper moisture content is crucial during compaction to achieve optimal particle interlock and prevent future settling or erosion. Mechanical compaction methods ensure long-term performance in applications like driveways, roads, and foundations compared to loose gravel, which tends to shift and degrade under load.

Comparing Load-Bearing Capacity: Compacted vs Loose Gravel

Compacted gravel exhibits significantly higher load-bearing capacity compared to loose gravel due to reduced air gaps and increased particle interlock, which distributes weight more evenly. Loose gravel, with its irregular particle arrangement and void spaces, tends to shift under pressure, leading to surface deformation and instability. Engineering studies indicate that compacted gravel can support loads up to 50% greater than loose gravel, making it essential for construction and roadway applications.

Drainage Performance: Loose Gravel vs Compacted Gravel

Loose gravel provides superior drainage performance due to its high porosity, allowing water to flow freely through the gaps between particles. In contrast, compacted gravel reduces pore spaces, slowing water infiltration and increasing the risk of surface water pooling or runoff. Optimal drainage is often achieved by balancing compaction levels to maintain structural stability while preserving adequate permeability.

Maintenance Requirements for Each Gravel Type

Gravel compaction significantly reduces maintenance requirements by creating a stable, dense surface that resists erosion, minimizes dust, and prevents weed growth. Loose gravel demands frequent upkeep, including regular raking, replenishment due to displacement, and dust control to maintain functionality and appearance. Proper compaction enhances longevity and reduces costs associated with gravel replacement and surface grading.

Cost Implications: Compaction vs No Compaction

Compacting gravel increases initial project costs due to the need for specialized equipment and labor but reduces long-term maintenance expenses by enhancing surface stability and load-bearing capacity. Loose gravel requires lower upfront investment but often leads to higher ongoing costs from frequent repairs and replenishment caused by erosion and displacement. Analyzing cost implications reveals that compaction, despite its higher initial expense, offers greater economic efficiency over time through reduced material loss and improved durability.

Environmental Impact: Compacted and Loose Gravel

Compacted gravel reduces soil erosion by creating a stable surface that minimizes water runoff, protecting nearby ecosystems from sediment buildup. Loose gravel, while more permeable and allowing better water infiltration, can lead to increased dust and potential displacement during heavy rainfall, contributing to sediment pollution in waterways. Choosing the appropriate gravel state balances environmental concerns, where compacted gravel supports erosion control and loose gravel promotes natural groundwater recharge.

Choosing the Right Gravel Approach for Your Project

Gravel compaction enhances stability and load-bearing capacity by reducing air gaps, making it ideal for driveways, pathways, and foundational bases. Loose gravel, while easier to install and drain, may shift under weight and require more frequent maintenance. Selecting between compacted and loose gravel depends on project requirements for durability, drainage, and budget constraints.

Gravel compaction vs loose gravel Infographic

materialdif.com

materialdif.com