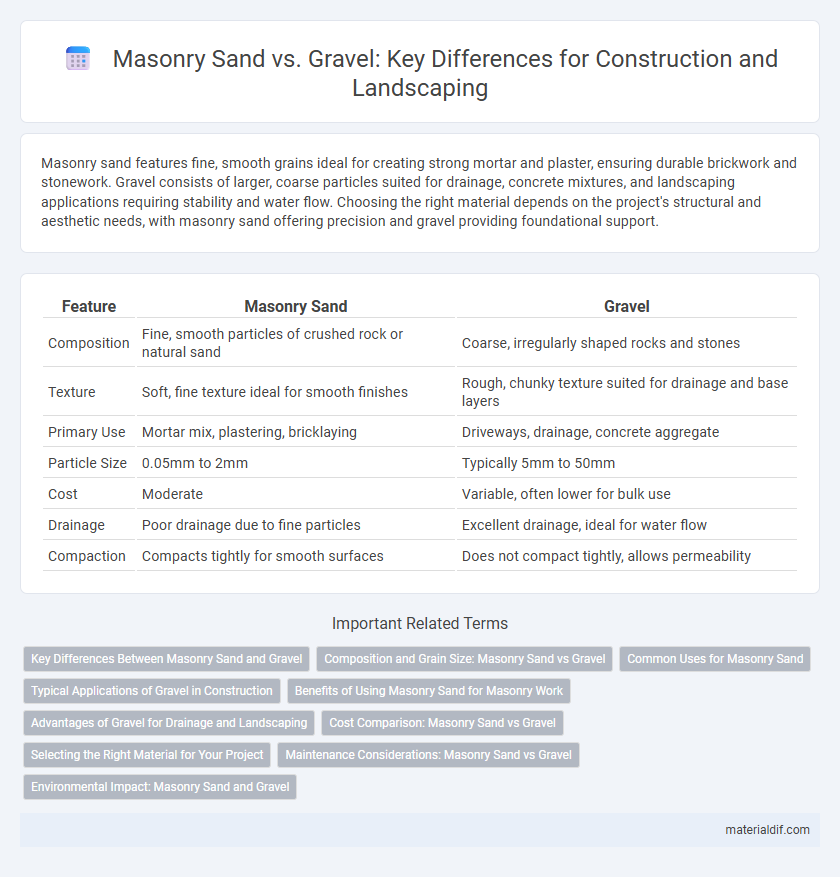

Masonry sand features fine, smooth grains ideal for creating strong mortar and plaster, ensuring durable brickwork and stonework. Gravel consists of larger, coarse particles suited for drainage, concrete mixtures, and landscaping applications requiring stability and water flow. Choosing the right material depends on the project's structural and aesthetic needs, with masonry sand offering precision and gravel providing foundational support.

Table of Comparison

| Feature | Masonry Sand | Gravel |

|---|---|---|

| Composition | Fine, smooth particles of crushed rock or natural sand | Coarse, irregularly shaped rocks and stones |

| Texture | Soft, fine texture ideal for smooth finishes | Rough, chunky texture suited for drainage and base layers |

| Primary Use | Mortar mix, plastering, bricklaying | Driveways, drainage, concrete aggregate |

| Particle Size | 0.05mm to 2mm | Typically 5mm to 50mm |

| Cost | Moderate | Variable, often lower for bulk use |

| Drainage | Poor drainage due to fine particles | Excellent drainage, ideal for water flow |

| Compaction | Compacts tightly for smooth surfaces | Does not compact tightly, allows permeability |

Key Differences Between Masonry Sand and Gravel

Masonry sand features fine grains with smooth edges, ideal for creating strong mortar mixes, while gravel consists of larger, coarse particles used mainly for drainage and structural support. Masonry sand enhances workability and consistency in bricklaying, whereas gravel provides stability and prevents erosion in foundations and driveways. The particle size and texture differences determine their specific applications in construction projects.

Composition and Grain Size: Masonry Sand vs Gravel

Masonry sand consists of finely crushed quartz and silica particles with grain sizes typically ranging from 0.1 to 0.5 millimeters, providing a smooth texture essential for mixing mortar. Gravel comprises larger, rounded rock fragments usually between 2 to 64 millimeters in diameter, composed of various rock types like limestone, granite, or basalt, offering greater structural strength and drainage capabilities. The distinct grain size and composition differences influence their specific applications, with masonry sand promoting bond strength in masonry work, while gravel serves in foundational and drainage uses.

Common Uses for Masonry Sand

Masonry sand is primarily used for mortar mixes, providing a smooth and workable consistency essential for bricklaying and block laying projects. Its fine texture enhances adhesion and creates a strong bond in masonry joints, making it ideal for tuckpointing and plastering applications. Unlike gravel, which is used for drainage and structural support, masonry sand is focused on finishing and surface-level construction tasks.

Typical Applications of Gravel in Construction

Gravel is widely used in construction for its excellent drainage properties and structural support, making it ideal for foundations, roadways, and concrete production. Unlike masonry sand, which is finer and best suited for mortar and plastering, gravel provides stability in base layers for driveways, walkways, and retaining walls. Its durability and ability to prevent water accumulation enhance the longevity and safety of various infrastructure projects.

Benefits of Using Masonry Sand for Masonry Work

Masonry sand offers superior fine texture and improved workability, making it ideal for achieving smooth and strong mortar joints in masonry work. Its consistent particle size enhances mortar bonding and reduces shrinkage and cracking compared to gravel. Using masonry sand results in durable, aesthetically pleasing brick and block constructions due to its optimized composition for structural integrity.

Advantages of Gravel for Drainage and Landscaping

Gravel offers superior drainage properties compared to masonry sand due to its larger, irregular particles that create air gaps, allowing water to flow freely and preventing water accumulation. This makes gravel ideal for landscaping projects such as walkways, driveways, and French drains, where effective water management is crucial. Its durability and natural aesthetic enhance soil stabilization and reduce erosion, promoting healthier plant growth and reducing maintenance needs.

Cost Comparison: Masonry Sand vs Gravel

Masonry sand typically costs $30 to $50 per ton, while gravel ranges from $10 to $50 per ton depending on type and location. Gravel is generally more affordable for large projects, but masonry sand offers finer texture ideal for mortar mixes, affecting overall material efficiency and labor costs. Choosing between masonry sand and gravel depends on budget constraints and specific project requirements, impacting total construction expenses.

Selecting the Right Material for Your Project

Selecting masonry sand or gravel depends on the specific requirements of your construction project. Masonry sand, with its fine texture and smooth consistency, is ideal for mortar mixes and finishing work, ensuring strong bonding and a polished appearance. Gravel, characterized by its coarse particles and excellent drainage properties, is best suited for foundational support, driveways, and drainage systems where stability and water flow are critical.

Maintenance Considerations: Masonry Sand vs Gravel

Masonry sand requires less frequent maintenance compared to gravel, as its fine particles compact tightly, reducing weed growth and erosion. Gravel, while offering better drainage, often demands regular raking and refilling to manage displacement and weed intrusion. Proper maintenance choices depend on the project's durability needs and aesthetic preferences.

Environmental Impact: Masonry Sand and Gravel

Masonry sand and gravel have distinct environmental impacts based on their extraction and usage processes; masonry sand is finely crushed and often sourced from riverbeds, which can disrupt aquatic ecosystems if not managed responsibly, while gravel extraction typically involves quarrying that alters landscapes and can lead to habitat loss. Both materials contribute to sediment runoff and water pollution if proper erosion control measures are not implemented during mining and transportation. Sustainable sourcing practices and reclamation efforts are essential to mitigate the environmental footprint of masonry sand and gravel in construction projects.

Masonry Sand vs Gravel Infographic

materialdif.com

materialdif.com