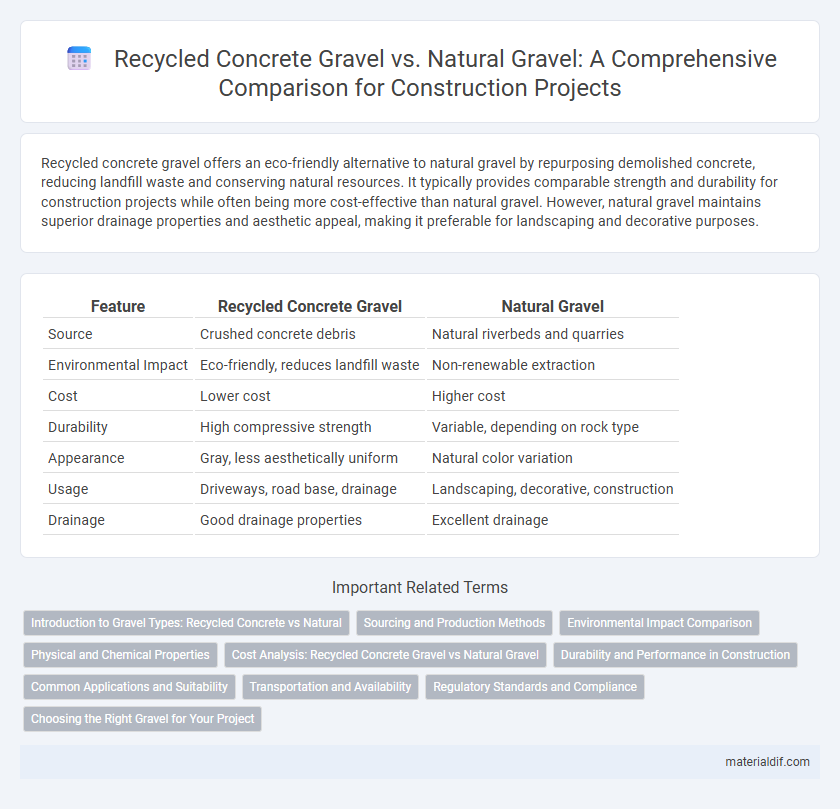

Recycled concrete gravel offers an eco-friendly alternative to natural gravel by repurposing demolished concrete, reducing landfill waste and conserving natural resources. It typically provides comparable strength and durability for construction projects while often being more cost-effective than natural gravel. However, natural gravel maintains superior drainage properties and aesthetic appeal, making it preferable for landscaping and decorative purposes.

Table of Comparison

| Feature | Recycled Concrete Gravel | Natural Gravel |

|---|---|---|

| Source | Crushed concrete debris | Natural riverbeds and quarries |

| Environmental Impact | Eco-friendly, reduces landfill waste | Non-renewable extraction |

| Cost | Lower cost | Higher cost |

| Durability | High compressive strength | Variable, depending on rock type |

| Appearance | Gray, less aesthetically uniform | Natural color variation |

| Usage | Driveways, road base, drainage | Landscaping, decorative, construction |

| Drainage | Good drainage properties | Excellent drainage |

Introduction to Gravel Types: Recycled Concrete vs Natural

Recycled concrete gravel consists of crushed concrete debris repurposed from demolition sites, offering a sustainable alternative with high durability and cost-effectiveness. Natural gravel forms through the weathering and erosion of rocks, providing a smoother texture and diverse mineral composition ideal for landscaping and drainage. Both materials serve critical roles in construction, with recycled concrete emphasizing environmental benefits while natural gravel prioritizes aesthetic and structural characteristics.

Sourcing and Production Methods

Recycled concrete gravel is sourced from demolished concrete structures and processed through crushing and screening, significantly reducing landfill waste and conserving natural resources. Natural gravel is extracted from riverbeds or quarries, involving extensive excavation that can disrupt ecosystems and deplete gravel beds. Production of recycled concrete gravel has lower environmental impact and energy consumption compared to the extraction and transportation processes needed for natural gravel.

Environmental Impact Comparison

Recycled concrete gravel significantly reduces landfill waste and decreases the demand for virgin materials, leading to lower environmental degradation compared to natural gravel extraction. It also minimizes carbon emissions by limiting quarrying activities and reducing transportation distances when sourced locally. Natural gravel, while effective for construction, often results in habitat disruption, increased erosion, and greater energy consumption during extraction and processing.

Physical and Chemical Properties

Recycled concrete gravel exhibits higher density and improved compaction compared to natural gravel, making it suitable for structural applications. It contains residual cementitious materials that contribute to increased alkalinity and potential chemical reactivity, unlike inert natural gravel comprised mainly of quartz, feldspar, and mica. The angular and rough texture of recycled concrete gravel enhances interlocking and load distribution, while natural gravel's rounded particles provide better drainage and reduced friction.

Cost Analysis: Recycled Concrete Gravel vs Natural Gravel

Recycled concrete gravel typically costs 15-40% less than natural gravel due to lower extraction and processing expenses. The use of recycled materials reduces transportation costs as it often comes from local demolition projects, further minimizing overall expenditure. Natural gravel prices fluctuate based on quarry location and scarcity, making recycled concrete gravel a more cost-effective and sustainable option for construction and landscaping projects.

Durability and Performance in Construction

Recycled concrete gravel offers enhanced durability in construction due to its angular shape and superior compaction properties, which improve load-bearing capacity and reduce settlement over time. Natural gravel, while often smoother and rounded, can result in less interlock, potentially compromising stability in high-stress applications. Studies show recycled concrete gravel provides comparable or better performance for road bases, foundations, and drainage systems, making it a sustainable alternative without sacrificing structural integrity.

Common Applications and Suitability

Recycled concrete gravel is commonly used in construction projects such as road bases, driveways, and drainage systems due to its high compressive strength and cost-effectiveness. Natural gravel is preferred for landscaping, decorative pathways, and areas requiring superior aesthetic appeal and natural permeability. Both materials suit different applications based on structural requirements and environmental considerations.

Transportation and Availability

Recycled concrete gravel offers significant advantages in transportation efficiency and availability due to its production from local demolition waste, reducing haul distances and associated costs compared to natural gravel, which often requires extraction from distant quarries. The abundant supply of recycled concrete gravel near urban centers ensures consistent accessibility, while natural gravel availability can be limited by geological constraints and environmental regulations. These factors make recycled concrete gravel a more sustainable and economically viable option for many construction projects.

Regulatory Standards and Compliance

Recycled concrete gravel must meet specific regulatory standards such as ASTM C33 to ensure proper particle size, contamination limits, and structural integrity for construction use. Natural gravel is typically subject to environmental regulations focusing on extraction permits and ecosystem impact, with fewer stringent specifications regarding composition. Both materials require compliance with local building codes and environmental guidelines to guarantee safety, durability, and sustainability in construction projects.

Choosing the Right Gravel for Your Project

Recycled concrete gravel offers a sustainable and cost-effective alternative to natural gravel, providing excellent durability and strength for construction projects. Natural gravel typically features superior aesthetic appeal and better drainage properties, making it ideal for landscaping and decorative applications. Evaluating project requirements such as load-bearing capacity, budget, and environmental impact is crucial to selecting the appropriate gravel type for optimal performance.

Recycled Concrete Gravel vs Natural Gravel Infographic

materialdif.com

materialdif.com