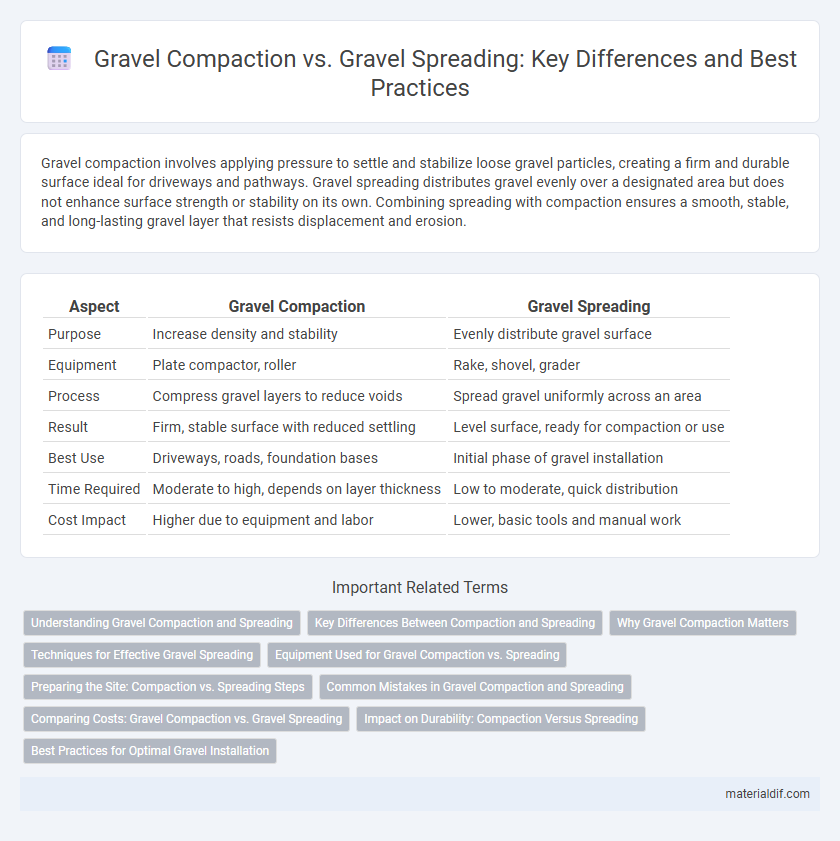

Gravel compaction involves applying pressure to settle and stabilize loose gravel particles, creating a firm and durable surface ideal for driveways and pathways. Gravel spreading distributes gravel evenly over a designated area but does not enhance surface strength or stability on its own. Combining spreading with compaction ensures a smooth, stable, and long-lasting gravel layer that resists displacement and erosion.

Table of Comparison

| Aspect | Gravel Compaction | Gravel Spreading |

|---|---|---|

| Purpose | Increase density and stability | Evenly distribute gravel surface |

| Equipment | Plate compactor, roller | Rake, shovel, grader |

| Process | Compress gravel layers to reduce voids | Spread gravel uniformly across an area |

| Result | Firm, stable surface with reduced settling | Level surface, ready for compaction or use |

| Best Use | Driveways, roads, foundation bases | Initial phase of gravel installation |

| Time Required | Moderate to high, depends on layer thickness | Low to moderate, quick distribution |

| Cost Impact | Higher due to equipment and labor | Lower, basic tools and manual work |

Understanding Gravel Compaction and Spreading

Gravel compaction involves the process of densifying loose gravel particles using mechanical equipment to increase stability and load-bearing capacity, which reduces air gaps and prevents future settling. Gravel spreading refers to evenly distributing gravel over a surface to create a uniform layer, essential for achieving consistent compaction and optimal surface drainage. Properly balancing gravel spreading and compaction ensures a durable base for driveways, roads, and construction projects, minimizing maintenance and improving longevity.

Key Differences Between Compaction and Spreading

Gravel compaction involves applying mechanical force to compress gravel particles, reducing voids and increasing density, which enhances stability and load-bearing capacity. Gravel spreading refers to the process of evenly distributing gravel over a surface to create a uniform layer without altering its density or particle arrangement. The key difference lies in compaction improving structural integrity and surface strength, while spreading focuses on coverage and thickness control.

Why Gravel Compaction Matters

Gravel compaction increases density by removing air gaps between particles, creating a stable and durable surface ideal for roads and driveways. Properly compacted gravel resists erosion, prevents shifting, and distributes loads more evenly, extending the lifespan of the installation. Gravel spreading alone cannot achieve this structural integrity, making compaction essential for long-term performance and safety.

Techniques for Effective Gravel Spreading

Techniques for effective gravel spreading involve even distribution using rakes or mechanical spreaders to avoid uneven surfaces and promote stability. Proper gravel compaction follows, utilizing rollers or plate compactors to increase density and prevent future settling. Ensuring the right moisture content before compaction enhances binding and durability of gravel surfaces.

Equipment Used for Gravel Compaction vs. Spreading

Gravel compaction typically requires heavy machinery such as vibratory plate compactors, rollers, or rammers to ensure particles are tightly bound, creating a solid and stable surface. For gravel spreading, equipment like motor graders, skid-steer loaders, or dump trucks with spreader attachments efficiently distribute the gravel evenly across the area. Using the correct equipment for each process directly affects surface durability and project efficiency in gravel construction tasks.

Preparing the Site: Compaction vs. Spreading Steps

Gravel compaction prepares the site by applying mechanical pressure to stabilize the base, ensuring a firm foundation that reduces future settling and increases load-bearing capacity. Gravel spreading involves evenly distributing the material across the surface, creating a uniform layer crucial for drainage and preventing uneven surfaces before compaction. Proper site preparation combines these steps to enhance pavement durability and minimize maintenance.

Common Mistakes in Gravel Compaction and Spreading

Common mistakes in gravel compaction include insufficient roller passes and neglecting moisture content, resulting in uneven surfaces and reduced stability. During gravel spreading, uneven distribution and failure to layer gravel properly often cause weak spots and erosion. Optimal compaction requires correct equipment and consistent pressure, while careful spreading maintains uniform thickness for long-lasting gravel roads or paths.

Comparing Costs: Gravel Compaction vs. Gravel Spreading

Gravel compaction typically incurs higher costs due to the need for specialized equipment like rollers or plate compactors and skilled labor to achieve optimal density and stability. Gravel spreading, while less expensive, often requires more frequent maintenance and replenishing as loose gravel shifts and settles over time. Evaluating long-term expenses reveals that investment in compaction may reduce ongoing costs by minimizing gravel displacement and enhancing surface durability.

Impact on Durability: Compaction Versus Spreading

Gravel compaction significantly enhances durability by increasing density and reducing voids, which minimizes water infiltration and prevents soil erosion. In contrast, gravel spreading without compaction results in looser layers prone to shifting and settling, reducing structural stability over time. Properly compacted gravel surfaces exhibit improved load-bearing capacity and longer lifespan compared to merely spread gravel.

Best Practices for Optimal Gravel Installation

Gravel compaction ensures a stable and durable surface by increasing density and reducing air gaps, which minimizes settling and erosion. Proper gravel spreading involves evenly distributing gravel in thin layers, preventing uneven surfaces and promoting better water drainage. Combining systematic spreading with mechanical compaction tools optimizes gravel installation, enhancing longevity and structural integrity.

Gravel compaction vs Gravel spreading Infographic

materialdif.com

materialdif.com