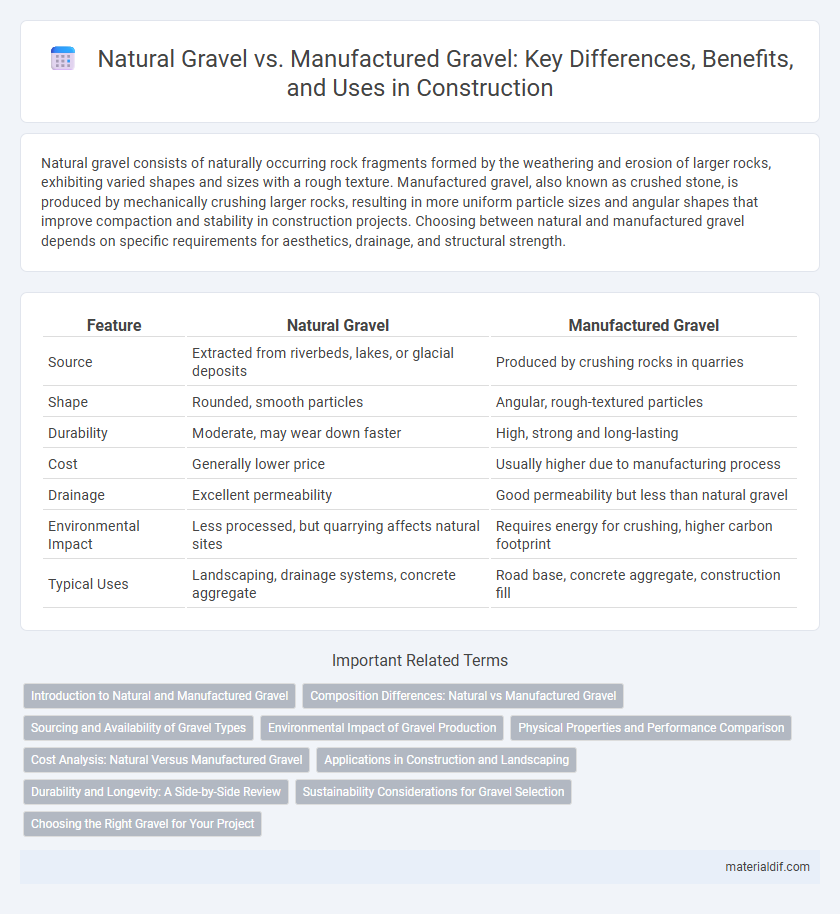

Natural gravel consists of naturally occurring rock fragments formed by the weathering and erosion of larger rocks, exhibiting varied shapes and sizes with a rough texture. Manufactured gravel, also known as crushed stone, is produced by mechanically crushing larger rocks, resulting in more uniform particle sizes and angular shapes that improve compaction and stability in construction projects. Choosing between natural and manufactured gravel depends on specific requirements for aesthetics, drainage, and structural strength.

Table of Comparison

| Feature | Natural Gravel | Manufactured Gravel |

|---|---|---|

| Source | Extracted from riverbeds, lakes, or glacial deposits | Produced by crushing rocks in quarries |

| Shape | Rounded, smooth particles | Angular, rough-textured particles |

| Durability | Moderate, may wear down faster | High, strong and long-lasting |

| Cost | Generally lower price | Usually higher due to manufacturing process |

| Drainage | Excellent permeability | Good permeability but less than natural gravel |

| Environmental Impact | Less processed, but quarrying affects natural sites | Requires energy for crushing, higher carbon footprint |

| Typical Uses | Landscaping, drainage systems, concrete aggregate | Road base, concrete aggregate, construction fill |

Introduction to Natural and Manufactured Gravel

Natural gravel is formed through the erosion and weathering of rocks over thousands of years, resulting in smooth, rounded particles with varied sizes and textures. Manufactured gravel, also known as crushed stone, is produced by mechanically crushing larger rocks, offering more uniform shapes and sizes suitable for construction and industrial applications. Both types of gravel serve distinct roles in infrastructure, landscaping, and drainage systems based on their physical properties and origin.

Composition Differences: Natural vs Manufactured Gravel

Natural gravel consists of rounded rock fragments formed and smoothed by natural weathering and water erosion processes, typically composed of a mix of quartz, basalt, granite, and other minerals. Manufactured gravel, also known as crushed stone, is produced by mechanically crushing larger rocks, resulting in angular particles that usually include limestone, granite, or trap rock. The compositional differences influence properties such as texture, durability, and suitability for construction projects where natural gravel offers better drainage while manufactured gravel provides stronger compaction.

Sourcing and Availability of Gravel Types

Natural gravel is sourced from riverbeds, glacial deposits, and sedimentary formations, relying heavily on geological availability and environmental factors, leading to regional variability in supply. Manufactured gravel, produced by crushing quarried rock such as granite or limestone, offers consistent quality and greater availability independent of natural deposits. The controlled production process ensures manufactured gravel meets specific construction standards, making it a reliable choice where natural gravel is scarce or ecologically sensitive areas restrict extraction.

Environmental Impact of Gravel Production

Natural gravel extraction disrupts riverbeds and aquatic ecosystems, leading to habitat loss and increased sedimentation that affects water quality. Manufactured gravel production consumes significant energy due to crushing and processing, contributing to higher carbon emissions compared to natural gravel. Sustainable gravel sourcing requires balancing ecological preservation with industrial demand by adopting responsible mining practices and energy-efficient manufacturing technologies.

Physical Properties and Performance Comparison

Natural gravel exhibits greater particle variability with rounded edges, enhancing compaction and drainage in construction applications. Manufactured gravel has more uniform angular particles, which improve interlock and strength in concrete mixes but may reduce workability. Physical differences impact performance; natural gravel offers better permeability, while manufactured gravel provides superior load-bearing capacity and durability in engineered structures.

Cost Analysis: Natural Versus Manufactured Gravel

Natural gravel typically incurs lower upfront costs due to minimal processing requirements, making it a cost-effective option for large-scale construction projects. Manufactured gravel, produced by crushing rocks, often has higher production expenses but offers consistent quality and particle size, potentially reducing long-term maintenance costs. Project-specific factors like availability, transportation, and durability significantly influence the overall cost-effectiveness of natural versus manufactured gravel.

Applications in Construction and Landscaping

Natural gravel, sourced from riverbeds and quarries, offers unique textures and durability ideal for road bases, concrete mix, and drainage systems due to its rounded particles and natural composition. Manufactured gravel, created by crushing rocks, provides consistent particle size and angular shapes, enhancing bonding in concrete and asphalt applications, making it highly suitable for pavements and structural fill. Both types serve crucial roles in landscaping, where natural gravel excels in aesthetic garden pathways and water features, while manufactured gravel supports stable foundations and decorative surfaces.

Durability and Longevity: A Side-by-Side Review

Natural gravel, formed through weathering and erosion over thousands of years, exhibits superior durability due to its rounded edges and naturally compacted structure, making it ideal for long-lasting construction and landscaping applications. Manufactured gravel, created by crushing larger rocks into angular fragments, offers consistent size and shape but can be more prone to breakage and wear, potentially reducing its longevity under heavy load or exposure. When comparing durability, natural gravel typically outperforms manufactured gravel in resisting abrasion and maintaining structural integrity over time.

Sustainability Considerations for Gravel Selection

Natural gravel, sourced from riverbeds and quarries, offers low embodied energy and minimal processing, promoting ecological balance by preserving soil structure and reducing habitat disruption. Manufactured gravel, produced through crushing hard rock, often consumes higher energy but provides consistent size and quality, aiding in optimized material use and reducing waste in construction projects. Sustainable gravel selection balances the environmental impact of extraction, transportation emissions, and durability, favoring local sourcing and recycled aggregate to minimize carbon footprint and conserve natural resources.

Choosing the Right Gravel for Your Project

Natural gravel offers irregular shapes and rough textures ideal for drainage and landscaping projects, while manufactured gravel provides uniform size and shape, making it suitable for concrete and road construction. Selecting the right gravel depends on project requirements such as load-bearing capacity, aesthetic appeal, and cost-effectiveness. Understanding the differences in composition and performance between natural and manufactured gravel ensures optimal durability and functionality for construction and design goals.

Natural Gravel vs Manufactured Gravel Infographic

materialdif.com

materialdif.com