River gravel features smooth, rounded stones shaped by natural water flow, making it ideal for decorative landscaping and drainage projects. Quarry gravel, with its rough, angular texture, offers superior compaction and stability, preferred for construction and road base applications. Choosing between river and quarry gravel depends on the specific requirements of aesthetics versus structural support.

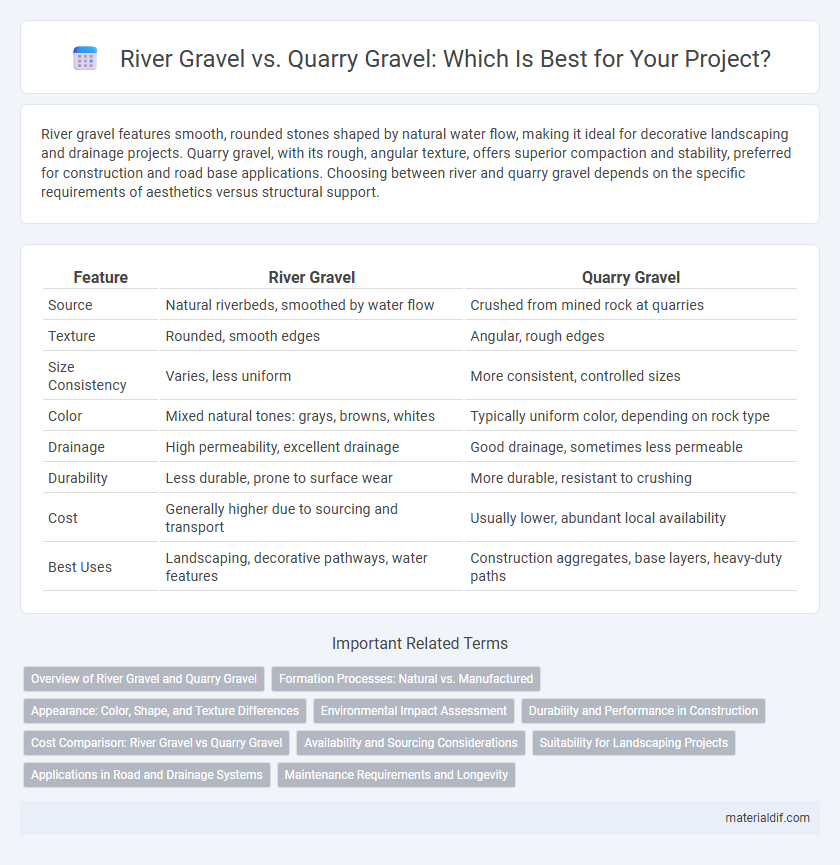

Table of Comparison

| Feature | River Gravel | Quarry Gravel |

|---|---|---|

| Source | Natural riverbeds, smoothed by water flow | Crushed from mined rock at quarries |

| Texture | Rounded, smooth edges | Angular, rough edges |

| Size Consistency | Varies, less uniform | More consistent, controlled sizes |

| Color | Mixed natural tones: grays, browns, whites | Typically uniform color, depending on rock type |

| Drainage | High permeability, excellent drainage | Good drainage, sometimes less permeable |

| Durability | Less durable, prone to surface wear | More durable, resistant to crushing |

| Cost | Generally higher due to sourcing and transport | Usually lower, abundant local availability |

| Best Uses | Landscaping, decorative pathways, water features | Construction aggregates, base layers, heavy-duty paths |

Overview of River Gravel and Quarry Gravel

River gravel consists of naturally rounded stones smoothed by water erosion, typically found in riverbeds, characterized by a range of colors and irregular shapes ideal for landscaping and drainage. Quarry gravel, sourced directly from rock crushing operations, features sharply angular particles with uniform size, making it highly suitable for construction projects requiring strong compaction and stability. Both types differ significantly in texture, appearance, and typical usage depending on project requirements.

Formation Processes: Natural vs. Manufactured

River gravel forms through natural processes as water currents smooth and round the stones over time, resulting in rounded, polished textures ideal for landscaping and drainage. Quarry gravel, produced by mechanically crushing larger rocks, has angular edges and a more uniform size distribution suited for construction and concrete aggregates. Understanding these formation differences is essential for selecting the right gravel type based on project requirements and aesthetic preferences.

Appearance: Color, Shape, and Texture Differences

River gravel typically exhibits smooth, rounded shapes with a polished texture due to natural water erosion, often showcasing a variety of earthy colors like browns, tans, and grays. Quarry gravel, in contrast, has angular, rough edges with a coarse texture resulting from mechanical crushing, usually featuring more uniform colors such as grays or whites. These differences in color, shape, and texture affect the aesthetic appeal and functional applications of each gravel type in landscaping and construction projects.

Environmental Impact Assessment

River gravel, naturally rounded and smooth, typically requires less processing, resulting in lower energy consumption and reduced environmental disturbance compared to quarry gravel, which involves blasting and crushing operations. Quarry gravel extraction can lead to significant habitat destruction, increased dust, noise pollution, and higher carbon emissions due to heavy machinery use, whereas river gravel harvesting might disrupt aquatic ecosystems and sediment flow if not managed properly. Environmental Impact Assessments must weigh the sediment transport alterations and biodiversity effects of river gravel extraction against the land degradation and pollution risks posed by quarrying activities.

Durability and Performance in Construction

River gravel offers superior durability and natural rounded edges that improve compaction and reduce voids, making it ideal for landscaping and drainage projects. Quarry gravel, with its angular and rough texture, provides excellent interlocking properties, enhancing stability and load-bearing capacity in concrete and road construction. Choosing between the two depends on project requirements, where river gravel performs well in aesthetic and water-related applications, while quarry gravel excels in structural and heavy-duty uses.

Cost Comparison: River Gravel vs Quarry Gravel

River gravel typically costs more than quarry gravel due to its natural sourcing, smooth texture, and aesthetic appeal favored in landscaping projects. Quarry gravel is generally cheaper, coming from crushed rock directly at the source, making it ideal for construction and large-scale infrastructure where budget constraints are critical. Pricing varies regionally but river gravel can cost up to 30-50% more per ton compared to quarry gravel, reflecting its niche applications and higher processing requirements.

Availability and Sourcing Considerations

River gravel, naturally smoothed by water currents, is often sourced from riverbeds and tends to be more abundant near water bodies, but its extraction is subject to environmental regulations limiting availability. Quarry gravel, quarried from rock deposits, is widely accessible year-round and offers more consistent supply due to controlled mining operations. Sourcing considerations include assessing local availability, transportation costs, and environmental impact regulations to determine the most practical and sustainable option.

Suitability for Landscaping Projects

River gravel features smooth, rounded edges ideal for garden pathways and decorative ground cover, promoting natural aesthetics and effective drainage. Quarry gravel consists of angular, sharp-edged stones providing superior stability and compaction, making it well-suited for base layers and driveways in landscaping projects. Choosing between the two depends on whether the project prioritizes visual appeal and comfort or structural support and durability.

Applications in Road and Drainage Systems

River gravel's rounded shape and smooth texture make it ideal for drainage systems, promoting efficient water flow and reducing clogging risks. Quarry gravel, with its angular and rough edges, provides superior stability and compaction, making it preferable for road base layers and heavy traffic areas. Both materials enhance infrastructure longevity, but selecting the right type depends on specific load-bearing and drainage requirements.

Maintenance Requirements and Longevity

River gravel features smoother, rounded stones that require less frequent cleaning due to natural erosion but may deteriorate faster under heavy traffic, impacting longevity. Quarry gravel offers jagged, angular edges that lock together firmly, enhancing stability and reducing displacement, leading to lower maintenance needs over time. The durable composition of quarry gravel typically results in extended lifespan compared to river gravel, making it ideal for high-traffic or load-bearing applications.

River gravel vs quarry gravel Infographic

materialdif.com

materialdif.com