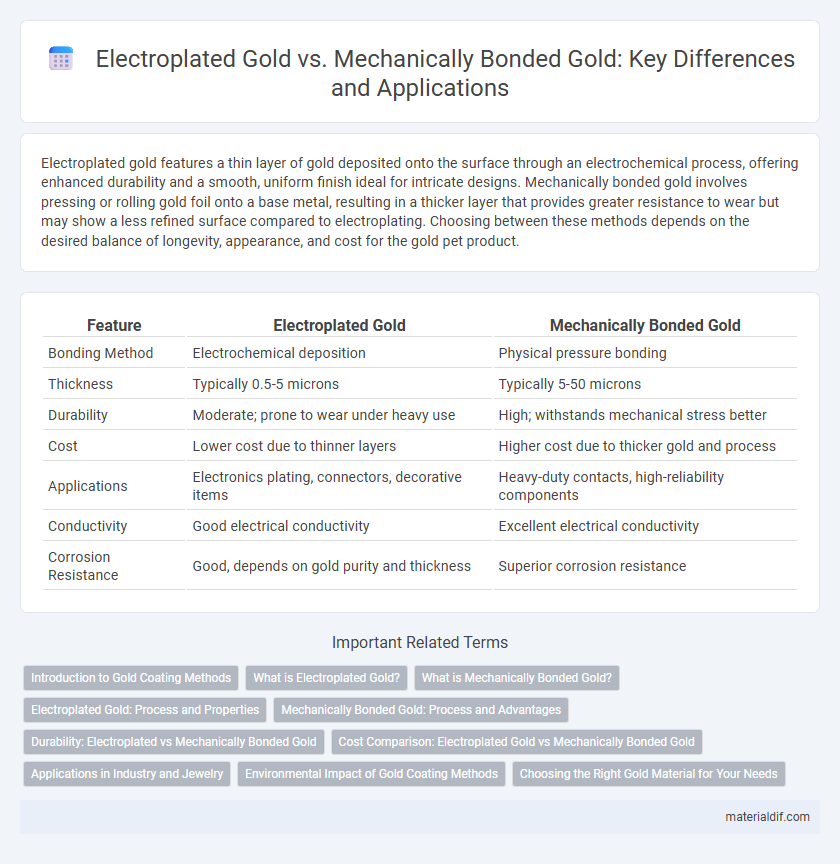

Electroplated gold features a thin layer of gold deposited onto the surface through an electrochemical process, offering enhanced durability and a smooth, uniform finish ideal for intricate designs. Mechanically bonded gold involves pressing or rolling gold foil onto a base metal, resulting in a thicker layer that provides greater resistance to wear but may show a less refined surface compared to electroplating. Choosing between these methods depends on the desired balance of longevity, appearance, and cost for the gold pet product.

Table of Comparison

| Feature | Electroplated Gold | Mechanically Bonded Gold |

|---|---|---|

| Bonding Method | Electrochemical deposition | Physical pressure bonding |

| Thickness | Typically 0.5-5 microns | Typically 5-50 microns |

| Durability | Moderate; prone to wear under heavy use | High; withstands mechanical stress better |

| Cost | Lower cost due to thinner layers | Higher cost due to thicker gold and process |

| Applications | Electronics plating, connectors, decorative items | Heavy-duty contacts, high-reliability components |

| Conductivity | Good electrical conductivity | Excellent electrical conductivity |

| Corrosion Resistance | Good, depends on gold purity and thickness | Superior corrosion resistance |

Introduction to Gold Coating Methods

Electroplated gold coating involves depositing a thin layer of gold onto a substrate using an electrical current, resulting in precise thickness control and improved corrosion resistance. Mechanically bonded gold, in contrast, relies on physical adhesion techniques such as rolling or bonding a gold foil directly onto the base material, offering enhanced durability and wear resistance. Both methods serve critical roles in electronics and jewelry, where gold's conductivity and aesthetic appeal are paramount.

What is Electroplated Gold?

Electroplated gold is a thin layer of gold applied to a base metal surface using an electrochemical process, ensuring a uniform and precise coating. This technique enhances corrosion resistance, electrical conductivity, and aesthetic appeal, commonly used in electronics and jewelry manufacturing. The thickness of electroplated gold typically ranges from 0.5 to 2.5 microns, offering cost-effective gold utilization compared to mechanically bonded gold.

What is Mechanically Bonded Gold?

Mechanically bonded gold refers to a layer of gold that is physically fused to a base metal through high pressure and heat, creating a durable and robust bond without the need for electroplating. This process ensures the gold layer maintains excellent wear resistance and longevity, making it ideal for high-friction applications such as jewelry and electronic connectors. Unlike electroplated gold, mechanically bonded gold offers superior adhesion and thickness, resulting in enhanced corrosion protection and a premium finish.

Electroplated Gold: Process and Properties

Electroplated gold involves depositing a thin layer of gold onto a substrate through an electrochemical process, ensuring uniform coverage and excellent adhesion. This method allows precise control over thickness, typically ranging from 0.1 to 10 microns, resulting in enhanced corrosion resistance and superior electrical conductivity. Electroplated gold surfaces are smooth and highly reflective, making them ideal for electronics, jewelry, and decorative applications.

Mechanically Bonded Gold: Process and Advantages

Mechanically bonded gold involves physically attaching a thin layer of gold to a substrate using pressure and heat, creating a durable, wear-resistant surface ideal for high-reliability applications such as aerospace and medical devices. This process ensures superior adhesion compared to electroplated gold, reducing the risk of flaking or peeling under mechanical stress. The enhanced mechanical strength and corrosion resistance make mechanically bonded gold a preferred choice for connectors and contacts in harsh environments.

Durability: Electroplated vs Mechanically Bonded Gold

Electroplated gold features a thin layer of gold applied through an electrochemical process, which may wear away more quickly under frequent use or abrasion. Mechanically bonded gold involves tightly fusing gold to the base metal using heat and pressure, resulting in a thicker, more durable coating resistant to chipping and scratching. For applications demanding long-term durability, mechanically bonded gold provides superior wear resistance compared to electroplated gold.

Cost Comparison: Electroplated Gold vs Mechanically Bonded Gold

Electroplated gold typically offers a lower-cost alternative compared to mechanically bonded gold due to its process efficiency and reduced material usage. Mechanically bonded gold involves a more complex manufacturing technique that increases labor and production costs, resulting in higher prices. Companies balancing budget and durability often prefer electroplated gold for economical applications while opting for mechanically bonded gold when long-term wear resistance justifies the investment.

Applications in Industry and Jewelry

Electroplated gold offers uniform thin coatings ideal for intricate jewelry designs and electronic connectors requiring precise conductivity, enhancing corrosion resistance and aesthetic appeal. Mechanically bonded gold provides thicker, more durable layers used in heavy-wear applications like industrial tools and high-end watch casings, ensuring long-lasting protection against abrasion. Industries select electroplating for fine detail work and cost efficiency, while mechanically bonded gold suits applications demanding robust mechanical strength and longevity.

Environmental Impact of Gold Coating Methods

Electroplated gold uses a chemical process involving toxic acids and heavy metals, producing hazardous waste that requires careful disposal to minimize environmental damage. Mechanically bonded gold coatings avoid chemical baths, significantly reducing harmful emissions and water pollution associated with electroplating. Choosing mechanically bonded gold can lead to a lower ecological footprint in electronics manufacturing and jewelry production.

Choosing the Right Gold Material for Your Needs

Electroplated gold offers a thin, uniform layer ideal for decorative items and low-wear applications due to its cost-effectiveness and aesthetic appeal. Mechanically bonded gold provides greater durability and wear resistance, making it suitable for industrial components and high-contact surfaces. Selecting the right gold material depends on balancing factors like application environment, budget constraints, and desired longevity.

Electroplated Gold vs Mechanically Bonded Gold Infographic

materialdif.com

materialdif.com