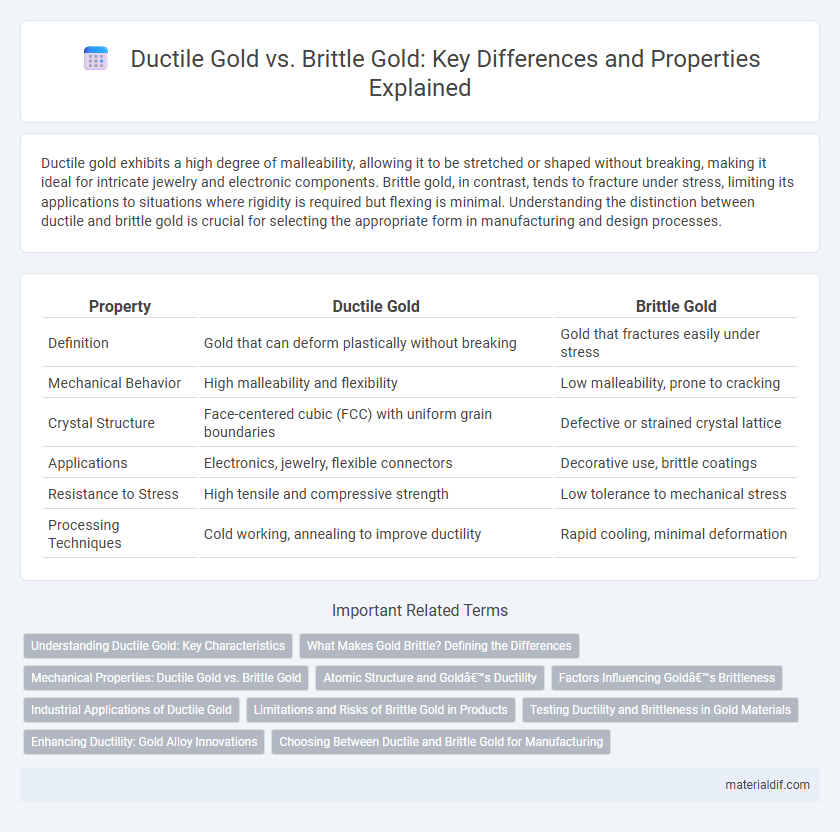

Ductile gold exhibits a high degree of malleability, allowing it to be stretched or shaped without breaking, making it ideal for intricate jewelry and electronic components. Brittle gold, in contrast, tends to fracture under stress, limiting its applications to situations where rigidity is required but flexing is minimal. Understanding the distinction between ductile and brittle gold is crucial for selecting the appropriate form in manufacturing and design processes.

Table of Comparison

| Property | Ductile Gold | Brittle Gold |

|---|---|---|

| Definition | Gold that can deform plastically without breaking | Gold that fractures easily under stress |

| Mechanical Behavior | High malleability and flexibility | Low malleability, prone to cracking |

| Crystal Structure | Face-centered cubic (FCC) with uniform grain boundaries | Defective or strained crystal lattice |

| Applications | Electronics, jewelry, flexible connectors | Decorative use, brittle coatings |

| Resistance to Stress | High tensile and compressive strength | Low tolerance to mechanical stress |

| Processing Techniques | Cold working, annealing to improve ductility | Rapid cooling, minimal deformation |

Understanding Ductile Gold: Key Characteristics

Ductile gold exhibits exceptional malleability and flexibility, allowing it to be stretched or bent without breaking, which is critical in jewelry making and electronic applications. Its atomic structure enables atoms to slide past each other under stress, preventing cracks and fractures commonly seen in brittle gold. This characteristic enhances durability and performance in environments requiring repeated bending or shaping.

What Makes Gold Brittle? Defining the Differences

Gold's brittleness primarily results from impurities and alloying elements altering its atomic structure, disrupting its natural ductility and causing it to fracture under stress. Pure gold is inherently ductile, able to deform extensively without breaking due to its face-centered cubic crystal lattice, while brittleness emerges when contaminants cause grain boundary weaknesses or phase separations. Understanding the differences involves analyzing the microstructural changes induced by factors such as excessive alloying, cold working, or improper heat treatment that compromise gold's malleability and make it prone to cracking.

Mechanical Properties: Ductile Gold vs. Brittle Gold

Ductile gold exhibits high tensile strength and significant plastic deformation before fracture, making it ideal for applications requiring flexibility and durability such as jewelry and electronics. Brittle gold, on the other hand, fractures under low strain with minimal deformation due to its high hardness and low ductility, limiting its use to environments where rigidity is essential. The mechanical properties contrast in yield strength, elongation, and impact resistance, influencing their performance in industrial and technological applications.

Atomic Structure and Gold’s Ductility

Gold's exceptional ductility stems from its atomic structure, which features a face-centered cubic (FCC) lattice allowing atoms to slide past one another with minimal resistance. This metallic bonding creates a malleable matrix, enabling gold to deform without fracturing, unlike brittle materials where atomic planes are more rigidly held and prone to crack propagation. Consequently, the FCC arrangement in gold atoms directly contributes to its capacity to be drawn into thin wires or hammered into sheets while maintaining structural integrity.

Factors Influencing Gold’s Brittleness

Gold's brittleness is influenced by factors such as impurity levels, temperature, and alloy composition. High-purity gold tends to be more ductile, while increased impurities and the presence of certain metals like silver or copper can enhance brittleness. Low temperatures also contribute to gold becoming more brittle by reducing atomic mobility within its crystalline structure.

Industrial Applications of Ductile Gold

Ductile gold's malleability and excellent electrical conductivity make it essential in industrial applications such as microelectronics, where it is used for wire bonding in semiconductor devices and connectors. Its ability to withstand deformation without breaking ensures reliable performance in flexible circuits and aerospace components. Industries favor ductile gold over brittle variants to enhance durability and minimize failure in high-precision manufacturing processes.

Limitations and Risks of Brittle Gold in Products

Brittle gold in products poses significant risks due to its tendency to crack or break under stress, compromising structural integrity and durability. Its limited flexibility reduces its effectiveness in applications requiring frequent bending or shaping, leading to premature failure. These limitations make brittle gold less suitable for jewelry and electronics where reliability and resilience are critical.

Testing Ductility and Brittleness in Gold Materials

Testing ductility and brittleness in gold materials involves tensile and bend tests to measure elongation and fracture points under stress. Ductile gold exhibits high plastic deformation before breaking, demonstrating its ability to withstand shaping and stretching without cracking. In contrast, brittle gold fractures with minimal deformation, indicating limited flexibility and a tendency to snap under lower stress levels.

Enhancing Ductility: Gold Alloy Innovations

Gold alloys with elements such as copper, silver, and palladium significantly enhance ductility by improving grain structure and reducing brittleness. Innovations in nanostructured gold alloys have further increased flexibility, making them ideal for applications requiring intricate shaping and durability. These advancements enable gold to maintain its malleability while providing increased resistance to cracking and deformation under stress.

Choosing Between Ductile and Brittle Gold for Manufacturing

Ductile gold, prized for its high malleability and excellent elongation, is ideal for precision manufacturing processes like fine wire drawing and intricate jewelry design. Brittle gold, though less common, is typically used in applications requiring hardness and wear resistance, such as certain electronic contacts and decorative coatings. Selecting between ductile and brittle gold depends on balancing mechanical properties with specific industrial needs, optimizing performance and durability.

Ductile Gold vs Brittle Gold Infographic

materialdif.com

materialdif.com