Gold wire offers superior flexibility and precision, making it ideal for intricate jewelry designs and detailed craftsmanship. Gold sheets provide a solid, uniform surface perfect for creating broad, flat elements or engraving, ensuring consistent thickness and durability. Choosing between gold wire and gold sheet depends on the specific requirements of texture, shape, and structural strength in your gold pet project.

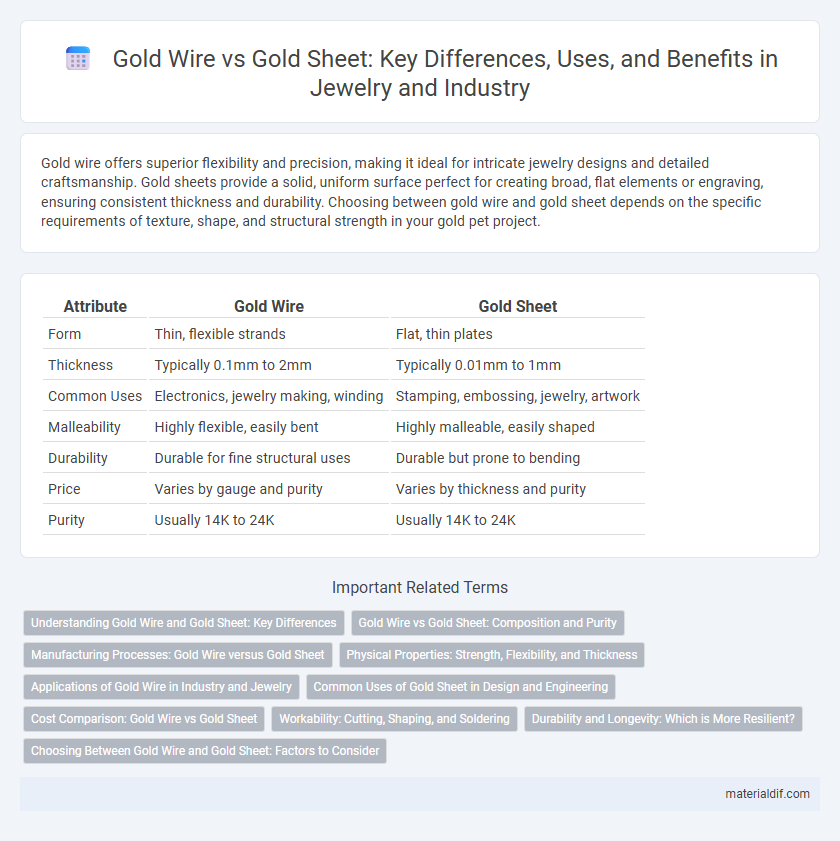

Table of Comparison

| Attribute | Gold Wire | Gold Sheet |

|---|---|---|

| Form | Thin, flexible strands | Flat, thin plates |

| Thickness | Typically 0.1mm to 2mm | Typically 0.01mm to 1mm |

| Common Uses | Electronics, jewelry making, winding | Stamping, embossing, jewelry, artwork |

| Malleability | Highly flexible, easily bent | Highly malleable, easily shaped |

| Durability | Durable for fine structural uses | Durable but prone to bending |

| Price | Varies by gauge and purity | Varies by thickness and purity |

| Purity | Usually 14K to 24K | Usually 14K to 24K |

Understanding Gold Wire and Gold Sheet: Key Differences

Gold wire offers superior flexibility and conductivity, making it ideal for intricate electronic components and fine jewelry designs, while gold sheets provide a flat, malleable surface suited for crafting, plating, and industrial applications. The wire's diameter varies significantly, allowing precise electrical connectivity in microelectronics, whereas sheets are typically measured in microns or millimeters, influencing their use in decorative or functional metalworking. Understanding these structural and functional distinctions helps optimize material selection based on project requirements involving gold's unique properties.

Gold Wire vs Gold Sheet: Composition and Purity

Gold wire and gold sheet differ primarily in form but often share similar compositions, typically ranging from 14K to 24K purity levels. Gold wire is drawn into thin, flexible strands preferred for intricate jewelry work and electronics, maintaining high purity standards often reaching 99.9% (24K) for specialized applications. In contrast, gold sheets are flat, uniform plates used in gilding, fabrication, or decorative arts, with purity tailored to specific needs, commonly available in 18K (75% gold) or 22K (91.6% gold) compositions.

Manufacturing Processes: Gold Wire versus Gold Sheet

Gold wire manufacturing involves drawing gold through progressively smaller dies to achieve precise diameters, ensuring flexibility and high tensile strength for applications in electronics and jewelry. Gold sheets are produced by rolling gold ingots into thin, flat layers through hot or cold rolling processes, offering uniform thickness ideal for decorative, industrial, and dental uses. The choice between wire and sheet depends on the production technique's control over thickness, surface finish, and mechanical properties tailored to specific end uses.

Physical Properties: Strength, Flexibility, and Thickness

Gold wire exhibits exceptional flexibility and tensile strength due to its elongated, cylindrical form, allowing it to withstand bending and stretching without breaking. Gold sheets, by contrast, provide uniform thickness and a larger surface area, making them ideal for applications requiring consistent flatness but exposing them to potential deformation under stress. Thickness in gold wire is generally much smaller in diameter compared to gold sheets, influencing their respective mechanical behaviors and suitability for different industrial or decorative uses.

Applications of Gold Wire in Industry and Jewelry

Gold wire is extensively used in the electronics industry for fine wiring in connectors, circuit boards, and bonding due to its excellent conductivity and corrosion resistance. In jewelry, gold wire allows for intricate designs and delicate craftsmanship, particularly in filigree and wire-wrapping techniques. Its flexibility and durability make it ideal for creating lightweight yet strong decorative pieces and functional components like clasps and chains.

Common Uses of Gold Sheet in Design and Engineering

Gold sheets are widely used in design and engineering for their flexibility, durability, and conductivity. They are essential in electronics for creating reliable connectors and circuit boards, as well as in decorative architectural elements and jewelry making. The malleability and corrosion resistance of gold sheets make them ideal for precision applications where both aesthetic and functional qualities are critical.

Cost Comparison: Gold Wire vs Gold Sheet

Gold wire typically costs more per gram than gold sheet due to the additional processing required to draw the metal into thin, flexible strands. Gold sheets, being easier to produce and handle, often provide a more economical option for applications requiring flat, uniform surfaces. However, price differences can vary based on purity, thickness, and market demand, impacting the overall cost efficiency of each form in jewelry and industrial uses.

Workability: Cutting, Shaping, and Soldering

Gold wire offers superior flexibility and ease in shaping, allowing precise bending and intricate designs, while gold sheets provide a stable surface but require more effort to cut and shape due to their rigidity. Cutting gold wire involves simple tools like wire cutters, whereas cutting gold sheets often demands specialized shears or saws for clean edges. Soldering gold wire is generally faster because smaller sections heat evenly, but soldering gold sheets requires careful temperature control to avoid warping or damaging the flat surface.

Durability and Longevity: Which is More Resilient?

Gold wire exhibits superior flexibility and resistance to fatigue, making it more durable in applications requiring bending or twisting. Gold sheets, while offering excellent corrosion resistance and surface durability, are prone to dents and scratches due to their flat and fragile form. For long-term resilience in dynamic environments, gold wire outperforms gold sheets by maintaining structural integrity under repetitive mechanical stress.

Choosing Between Gold Wire and Gold Sheet: Factors to Consider

Choosing between gold wire and gold sheet depends on the intended application, with gold wire offering superior flexibility and intricate detailing for jewelry or electronic components, while gold sheet provides a flat, durable surface ideal for plating or crafting larger, uniform pieces. Consider factors such as thickness, malleability, and the complexity of design, as gold wire allows for delicate, three-dimensional structures, whereas gold sheets facilitate more straightforward shaping and embossing. Cost implications and metal purity also influence the decision, with both forms available in various karats to match aesthetic preferences and functional requirements.

Gold Wire vs Gold Sheet Infographic

materialdif.com

materialdif.com