Selvedge denim features tightly woven edges that prevent unraveling, offering superior durability and a cleaner finish compared to non-selvedge denim. Non-selvedge denim is produced on wider modern looms, resulting in fabric with less defined edges and generally lower cost. Choosing selvedge denim ensures longevity and a premium look, making it ideal for pet accessories that withstand daily wear.

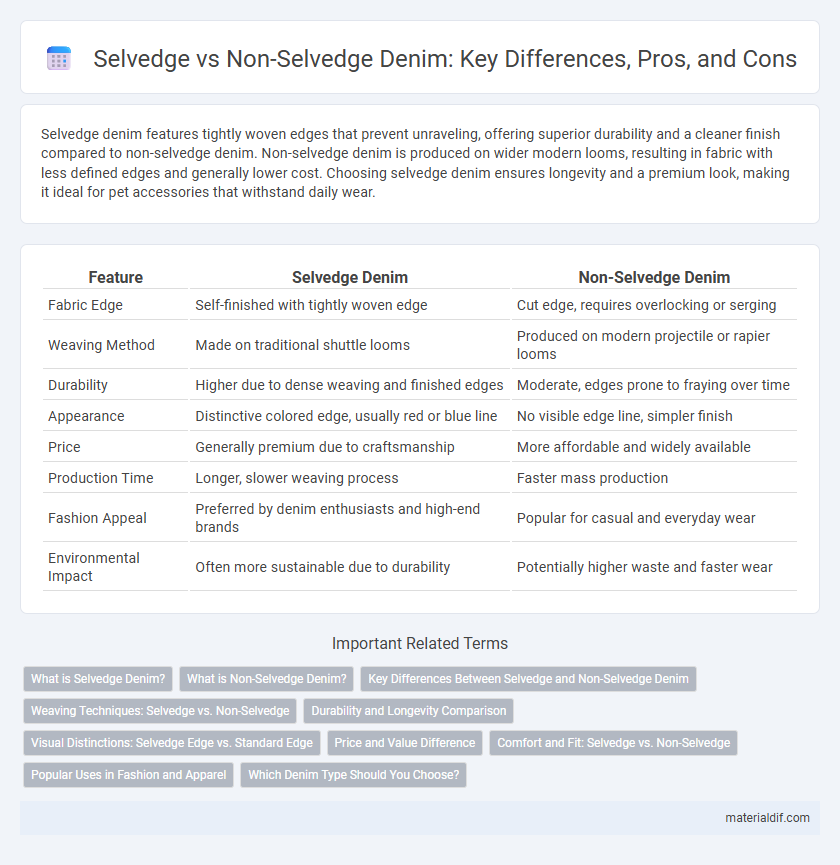

Table of Comparison

| Feature | Selvedge Denim | Non-Selvedge Denim |

|---|---|---|

| Fabric Edge | Self-finished with tightly woven edge | Cut edge, requires overlocking or serging |

| Weaving Method | Made on traditional shuttle looms | Produced on modern projectile or rapier looms |

| Durability | Higher due to dense weaving and finished edges | Moderate, edges prone to fraying over time |

| Appearance | Distinctive colored edge, usually red or blue line | No visible edge line, simpler finish |

| Price | Generally premium due to craftsmanship | More affordable and widely available |

| Production Time | Longer, slower weaving process | Faster mass production |

| Fashion Appeal | Preferred by denim enthusiasts and high-end brands | Popular for casual and everyday wear |

| Environmental Impact | Often more sustainable due to durability | Potentially higher waste and faster wear |

What is Selvedge Denim?

Selvedge denim is a high-quality fabric woven on traditional shuttle looms that create tightly bound edges preventing unraveling. This distinct edge, or "self-edge," is visible on the inside seam, often finished with a colored line such as red or blue, signaling authenticity. Compared to non-selvedge denim produced on modern looms, selvedge denim offers superior durability, a cleaner finish, and develops unique fades over time.

What is Non-Selvedge Denim?

Non-selvedge denim is produced on modern shuttleless looms, resulting in fabric edges that are unfinished and prone to fraying without additional stitching. Unlike selvedge denim, which has clean, self-finished edges created by traditional shuttle looms, non-selvedge denim is typically wider and more cost-effective to manufacture. This type of denim is commonly used in mass-produced jeans, offering greater fabric width and flexibility in design but lacking the distinctive edge detail favored by denim enthusiasts.

Key Differences Between Selvedge and Non-Selvedge Denim

Selvedge denim is woven on traditional shuttle looms, resulting in tightly woven edges that prevent fraying, while non-selvedge denim is produced on modern projectile looms with unfinished edges requiring overlocking. The durability of selvedge denim is higher due to its dense weave and thicker yarns, whereas non-selvedge denim often features a looser weave and lighter weight, making it less rugged but more affordable. Visually, selvedge denim displays a distinctive edge line typically with colored threads, prized in raw denim jeans, contrasting with the plain cut edges of non-selvedge denim that lack this signature detail.

Weaving Techniques: Selvedge vs. Non-Selvedge

Selvedge denim is woven on traditional shuttle looms that create a tightly bound edge to prevent fraying, characterized by a clean, finished selvage line often visible when cuffs are rolled. Non-selvedge denim is produced by modern projectile or rapier looms that weave faster but leave unfinished edges, requiring overlocking or serging to prevent unraveling. The weaving technique of selvedge denim contributes to its durability, unique texture, and higher production costs compared to non-selvedge denim.

Durability and Longevity Comparison

Selvedge denim features a tightly woven edge that prevents unraveling, significantly enhancing its durability compared to non-selvedge denim, which often uses a looser weave prone to fraying. The robust construction of selvedge denim allows it to withstand prolonged wear and frequent washing without losing integrity, contributing to superior longevity. Non-selvedge denim, while generally more affordable, tends to break down faster due to less stringent weaving techniques, resulting in shorter lifespan garments.

Visual Distinctions: Selvedge Edge vs. Standard Edge

Selvedge denim features a tightly woven edge with a clean, finished look often highlighted by a colored thread, commonly red or white, running along the outseam. In contrast, non-selvedge denim has a standard edge that is stitched or overlocked, resulting in a frayed appearance prone to unraveling without additional hemming. The distinct visual crispness of selvedge edges makes them a hallmark of premium denim craftsmanship, easily recognizable on jeans cuffs and hems.

Price and Value Difference

Selvedge denim typically commands a higher price due to its traditional shuttle loom production, which ensures durability and a cleaner edge finish, enhancing the overall garment longevity and quality. Non-selvedge denim, produced on faster modern looms, is often more affordable but may sacrifice durability and distinctive aesthetic appeal compared to selvedge. Investing in selvedge denim offers better long-term value through premium craftsmanship and a unique fading process, while non-selvedge denim suits budget-conscious consumers prioritizing initial cost over heritage and longevity.

Comfort and Fit: Selvedge vs. Non-Selvedge

Selvedge denim offers a tighter weave that molds to the body over time, providing a more personalized and comfortable fit compared to non-selvedge denim. Non-selvedge denim tends to have a looser weave, which can feel lighter and less rigid but may lack the tailored fit achieved through the natural aging process of selvedge. The durability of selvedge also maintains fit integrity longer, while non-selvedge denim might stretch out more quickly with wear.

Popular Uses in Fashion and Apparel

Selvedge denim is highly favored in premium fashion and artisanal apparel for its durability and distinctive edge, often showcased in raw or minimally washed jeans and jackets. Non-selvedge denim dominates mass-market clothing due to its cost-effectiveness and versatility, commonly used in fast fashion and trend-driven collections. Both types influence streetwear, heritage styles, and sustainable fashion segments, with selvedge representing craftsmanship and non-selvedge accommodating broader consumer markets.

Which Denim Type Should You Choose?

Selvedge denim, known for its tightly woven edges and premium construction, offers durability and a clean finish ideal for high-quality jeans. Non-selvedge denim, typically machine-made with wider looms, provides more variety and affordability, making it suitable for everyday wear. Choose selvedge for longevity and craftsmanship, or non-selvedge for budget-friendly, versatile denim options.

Selvedge vs non-selvedge Infographic

materialdif.com

materialdif.com