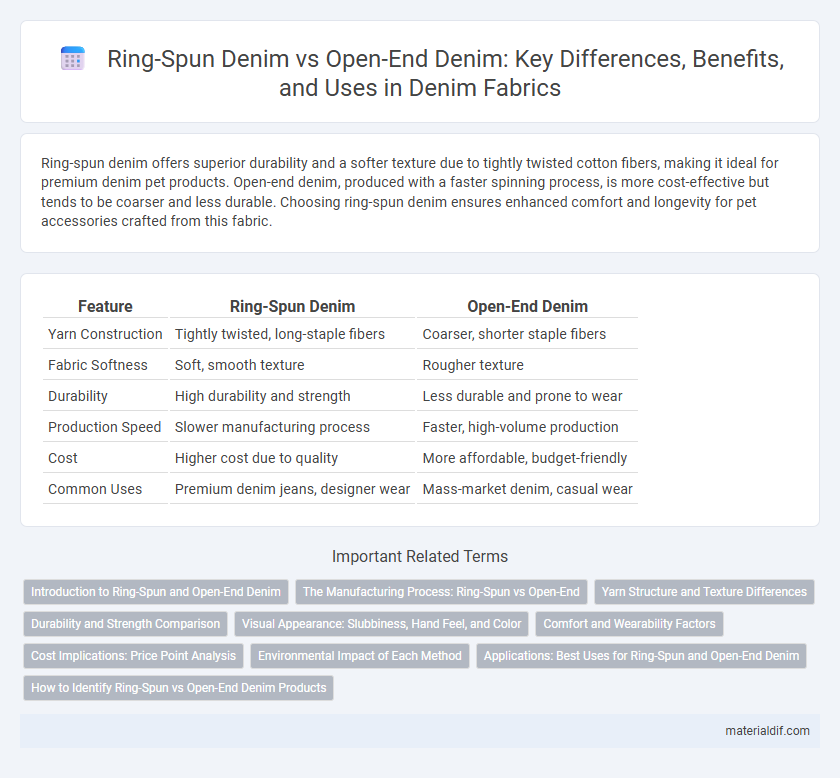

Ring-spun denim offers superior durability and a softer texture due to tightly twisted cotton fibers, making it ideal for premium denim pet products. Open-end denim, produced with a faster spinning process, is more cost-effective but tends to be coarser and less durable. Choosing ring-spun denim ensures enhanced comfort and longevity for pet accessories crafted from this fabric.

Table of Comparison

| Feature | Ring-Spun Denim | Open-End Denim |

|---|---|---|

| Yarn Construction | Tightly twisted, long-staple fibers | Coarser, shorter staple fibers |

| Fabric Softness | Soft, smooth texture | Rougher texture |

| Durability | High durability and strength | Less durable and prone to wear |

| Production Speed | Slower manufacturing process | Faster, high-volume production |

| Cost | Higher cost due to quality | More affordable, budget-friendly |

| Common Uses | Premium denim jeans, designer wear | Mass-market denim, casual wear |

Introduction to Ring-Spun and Open-End Denim

Ring-spun denim is produced by twisting and thinning cotton fibers to create a stronger, finer yarn that results in a softer and more durable fabric. Open-end denim, on the other hand, is made using a centrifugal spinning process that is faster and more cost-effective but yields a coarser and heavier texture. The difference in spinning techniques affects the fabric's texture, durability, and overall quality, making ring-spun denim ideal for premium apparel while open-end denim suits budget-friendly options.

The Manufacturing Process: Ring-Spun vs Open-End

Ring-spun denim is crafted by continuously twisting and thinning cotton fibers, producing a strong, smooth yarn that results in durable and high-quality fabric with a soft hand feel. Open-end denim utilizes a more rapid spinning method, where fibers are fed into a rotor and spun at high speeds, creating yarn with a coarser texture and lower tensile strength. The manufacturing process significantly impacts the denim's texture, durability, and appearance, with ring-spun offering superior quality but higher production costs compared to open-end.

Yarn Structure and Texture Differences

Ring-spun denim features yarns that are tightly twisted from long fibers, resulting in a finer, stronger, and smoother yarn structure with a soft hand feel and pronounced diagonal weave texture. Open-end denim uses yarns made from shorter fibers spun with a rotor technique, producing a coarser, bulkier yarn with a rougher texture and less definition in the weave pattern. The distinct yarn structures lead to ring-spun denim having greater durability and a more refined appearance, while open-end denim offers a heavier, more rugged texture and is typically more cost-effective.

Durability and Strength Comparison

Ring-spun denim exhibits superior durability and strength compared to open-end denim due to its tightly twisted yarn construction, resulting in higher tensile strength and resistance to wear and tear. Open-end denim, produced with less tightly spun yarns, tends to be bulkier but less durable, making it more prone to pilling and abrasion over time. The enhanced fiber alignment in ring-spun denim provides a smoother texture and greater longevity, ideal for heavy-duty denim applications.

Visual Appearance: Slubbiness, Hand Feel, and Color

Ring-spun denim exhibits a smoother, more refined visual appearance with minimal slubbiness, resulting in a softer hand feel and richer color depth due to tighter yarn twists. Open-end denim shows pronounced slubbiness, giving it a textured, more rustic look, accompanied by a rougher hand feel and typically less vibrant color saturation. The differences in yarn construction directly influence the fabric's tactile experience and aesthetic qualities, making ring-spun denim ideal for premium, polished finishes while open-end denim suits casual, rugged styles.

Comfort and Wearability Factors

Ring-spun denim features finer, tightly twisted yarns that provide superior softness and enhanced comfort compared to open-end denim, which uses coarser, bulkier fibers. The smooth texture of ring-spun denim reduces skin irritation and improves breathability, making it ideal for prolonged wear. In contrast, open-end denim is more durable but less flexible, often resulting in a stiffer, less comfortable feel over time.

Cost Implications: Price Point Analysis

Ring-spun denim typically commands a higher price point due to its labor-intensive spinning process, resulting in finer yarns and superior fabric durability. Open-end denim offers a more cost-effective alternative by utilizing a faster spinning technique that produces thicker, less refined yarns, leading to lower production expenses. Brands must weigh these cost implications against quality preferences to determine the best fit for their target market.

Environmental Impact of Each Method

Ring-spun denim production generates less waste and consumes less water compared to open-end denim, making it a more sustainable choice. The open-end spinning process typically requires higher energy consumption and emits more pollutants due to its faster, less controlled fiber integration. Opting for ring-spun denim supports reduced environmental footprints by promoting efficient resource use and minimizing chemical runoff.

Applications: Best Uses for Ring-Spun and Open-End Denim

Ring-spun denim is ideal for premium apparel requiring superior softness, durability, and a refined texture, commonly used in high-end jeans, jackets, and vintage-style garments. Open-end denim excels in mass-produced, budget-friendly clothing such as casual wear and workwear due to its faster production process and coarser texture. Selecting between ring-spun and open-end denim depends on desired fabric quality, cost considerations, and end-use performance requirements.

How to Identify Ring-Spun vs Open-End Denim Products

Ring-spun denim features tightly twisted yarns that create a smooth, durable fabric with a distinct diagonal weave pattern, while open-end denim is made from coarser, loosely twisted yarns resulting in a rougher texture and less defined weave. To identify ring-spun denim, look for a softer hand feel, visible twill lines, and greater resistance to fraying; open-end denim feels rougher, has a more uniform surface, and often shows less pronounced diagonal patterns. Examining the yarn structure under magnification reveals the finer, tighter fibers of ring-spun denim compared to the thicker, bulkier strands found in open-end denim.

Ring-spun denim vs Open-end denim Infographic

materialdif.com

materialdif.com