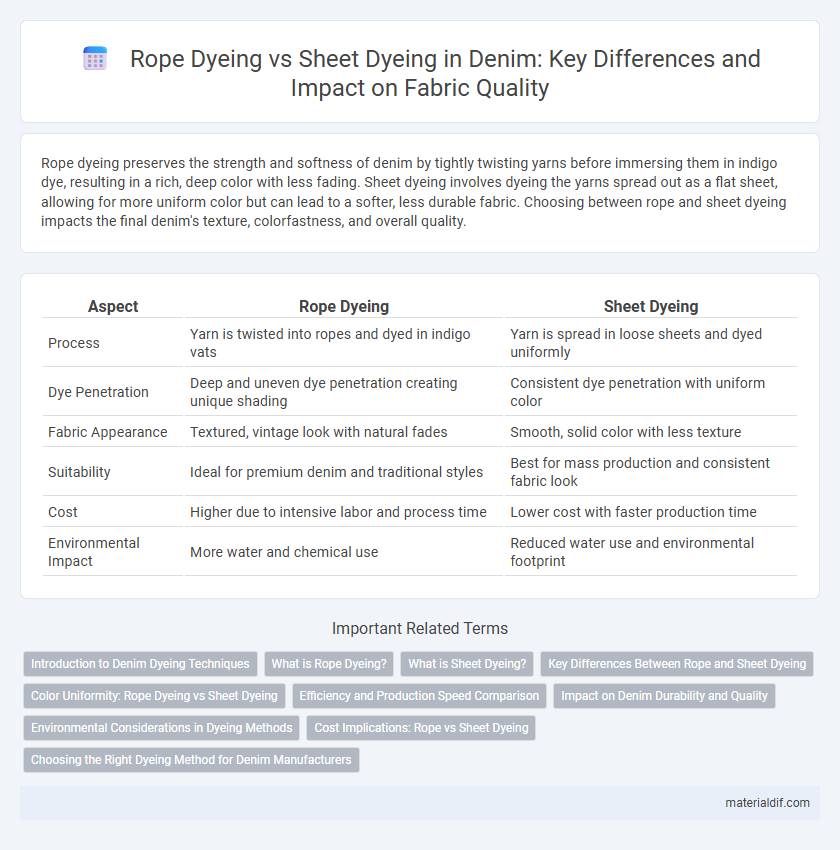

Rope dyeing preserves the strength and softness of denim by tightly twisting yarns before immersing them in indigo dye, resulting in a rich, deep color with less fading. Sheet dyeing involves dyeing the yarns spread out as a flat sheet, allowing for more uniform color but can lead to a softer, less durable fabric. Choosing between rope and sheet dyeing impacts the final denim's texture, colorfastness, and overall quality.

Table of Comparison

| Aspect | Rope Dyeing | Sheet Dyeing |

|---|---|---|

| Process | Yarn is twisted into ropes and dyed in indigo vats | Yarn is spread in loose sheets and dyed uniformly |

| Dye Penetration | Deep and uneven dye penetration creating unique shading | Consistent dye penetration with uniform color |

| Fabric Appearance | Textured, vintage look with natural fades | Smooth, solid color with less texture |

| Suitability | Ideal for premium denim and traditional styles | Best for mass production and consistent fabric look |

| Cost | Higher due to intensive labor and process time | Lower cost with faster production time |

| Environmental Impact | More water and chemical use | Reduced water use and environmental footprint |

Introduction to Denim Dyeing Techniques

Rope dyeing involves twisting yarns into ropes before immersion in indigo dye, ensuring deeper color penetration and enhanced fabric strength, making it ideal for high-quality denim. Sheet dyeing, on the other hand, dyes fabric in open sheets which yields a softer texture but less durable colorfastness. These techniques significantly influence denim's appearance, durability, and aging characteristics in fashion and apparel manufacturing.

What is Rope Dyeing?

Rope dyeing is a textile dyeing technique where yarns are twisted into a rope form and then immersed in indigo dye baths to achieve deep, uniform coloration ideal for denim production. This method allows multiple dyeing cycles without excessive yarn damage, resulting in a rich blue tone characteristic of high-quality denim. Rope dyeing enhances fabric strength and provides distinct fading patterns, making it preferred over sheet dyeing for premium denim manufacturing.

What is Sheet Dyeing?

Sheet dyeing is a textile dyeing technique where dyed sheets of fabric are produced by passing the fabric through dye baths and then through rollers that squeeze out excess dye while maintaining uniform color distribution. This process ensures even penetration of dye across the fabric surface, resulting in consistent color fastness and minimal variation. Widely used for denim production, sheet dyeing offers efficient color application and improved fabric quality compared to conventional methods like rope dyeing.

Key Differences Between Rope and Sheet Dyeing

Rope dyeing involves twisting yarns into a rope form before passing them through indigo dye vats, enabling uniform color penetration and better stretch recovery, making it ideal for high-quality denim. Sheet dyeing spreads yarns in a flat sheet, enhancing mass production efficiency and reducing dye consumption but may result in less consistent color absorption. Key differences include the yarn configuration, dye uniformity, production speed, and suitability for specific denim quality requirements.

Color Uniformity: Rope Dyeing vs Sheet Dyeing

Rope dyeing ensures superior color uniformity by tightly twisting yarns into bundles, allowing even penetration of indigo dye on all sides. Sheet dyeing, however, exposes fabric in broad, flat layers, which can result in inconsistent dye absorption and uneven coloration. This difference makes rope dyeing the preferred method for producing premium denim with rich, uniform indigo hues.

Efficiency and Production Speed Comparison

Rope dyeing offers higher efficiency by allowing multiple yarns to be dyed simultaneously with deeper dye penetration, which enhances color uniformity in denim production. In contrast, sheet dyeing processes yarns in flat bundles, resulting in slower production speeds and less consistent dye absorption. Manufacturers prioritize rope dyeing to maximize throughput and reduce cycle times, making it the preferred choice for large-scale denim fabric production.

Impact on Denim Durability and Quality

Rope dyeing penetrates yarn bundles thoroughly, resulting in superior indigo coverage and enhanced denim durability compared to sheet dyeing. Sheet dyeing, which dyes individual yarn layers, often leads to uneven color absorption and lower abrasion resistance. The tightly packed fiber structure achieved in rope dyeing contributes to higher fabric strength and improved long-term wear quality.

Environmental Considerations in Dyeing Methods

Rope dyeing uses less water and energy compared to sheet dyeing, significantly reducing environmental impact in denim production. The concentrated indigo dye in rope dyeing minimizes chemical use and wastewater generation, making it a more sustainable option. Sheet dyeing, while efficient in uniform color application, typically consumes higher volumes of water and chemicals, posing greater environmental challenges.

Cost Implications: Rope vs Sheet Dyeing

Rope dyeing generally incurs higher initial investment costs due to specialized machinery and longer processing times but offers superior color penetration and fabric quality, reducing re-dyeing expenses over time. Sheet dyeing, while more cost-effective in setup and faster for mass production, may result in less uniform dyeing and higher risks of defects, potentially increasing waste and finishing costs. Manufacturers must weigh the balance between upfront expenses and long-term fabric performance when selecting between rope and sheet dyeing techniques.

Choosing the Right Dyeing Method for Denim Manufacturers

Rope dyeing offers superior color penetration and uniformity, making it ideal for high-quality denim requiring deep indigo hues and long-lasting colorfastness. Sheet dyeing provides faster processing and lower water consumption, catering to manufacturers prioritizing environmental sustainability and cost efficiency. Denim manufacturers must balance production scale, fabric quality, and environmental impact when selecting between rope dyeing and sheet dyeing methods.

Rope dyeing vs sheet dyeing Infographic

materialdif.com

materialdif.com