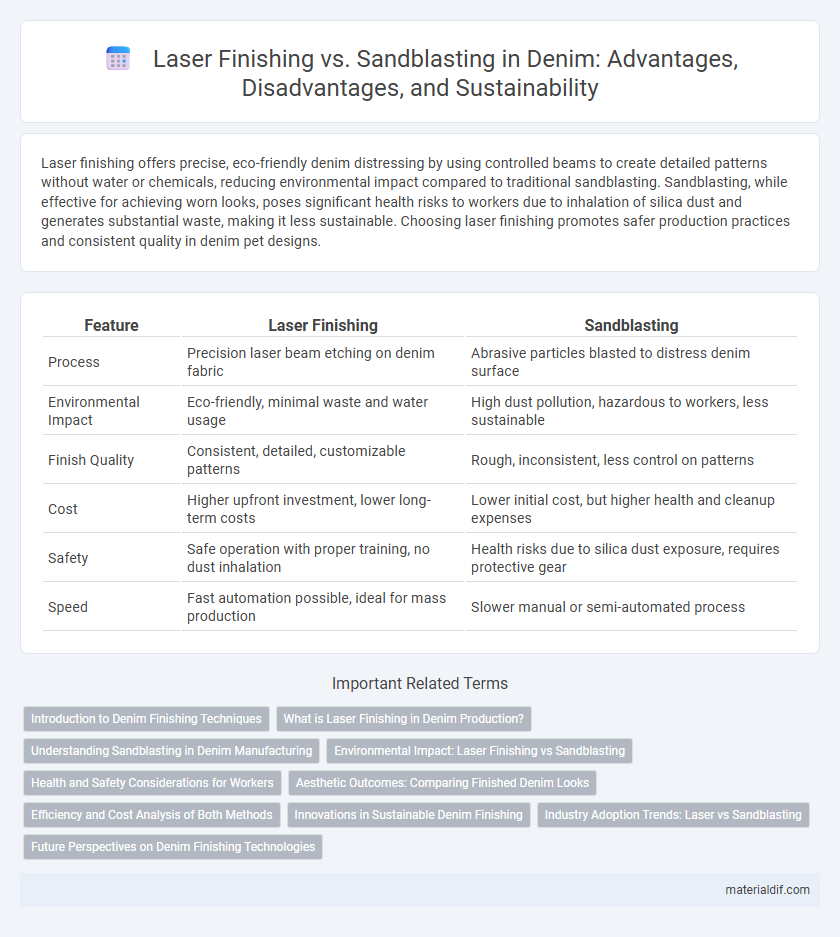

Laser finishing offers precise, eco-friendly denim distressing by using controlled beams to create detailed patterns without water or chemicals, reducing environmental impact compared to traditional sandblasting. Sandblasting, while effective for achieving worn looks, poses significant health risks to workers due to inhalation of silica dust and generates substantial waste, making it less sustainable. Choosing laser finishing promotes safer production practices and consistent quality in denim pet designs.

Table of Comparison

| Feature | Laser Finishing | Sandblasting |

|---|---|---|

| Process | Precision laser beam etching on denim fabric | Abrasive particles blasted to distress denim surface |

| Environmental Impact | Eco-friendly, minimal waste and water usage | High dust pollution, hazardous to workers, less sustainable |

| Finish Quality | Consistent, detailed, customizable patterns | Rough, inconsistent, less control on patterns |

| Cost | Higher upfront investment, lower long-term costs | Lower initial cost, but higher health and cleanup expenses |

| Safety | Safe operation with proper training, no dust inhalation | Health risks due to silica dust exposure, requires protective gear |

| Speed | Fast automation possible, ideal for mass production | Slower manual or semi-automated process |

Introduction to Denim Finishing Techniques

Laser finishing and sandblasting are prominent denim finishing techniques used to create unique textures and aesthetic effects on jeans. Laser finishing employs high-precision laser beams to produce detailed patterns and fades, offering environmentally-friendly advantages by minimizing water and chemical usage. Sandblasting, which blasts abrasive materials onto denim fabric, provides a worn and distressed look but raises significant health and environmental concerns due to silica dust exposure.

What is Laser Finishing in Denim Production?

Laser finishing in denim production uses concentrated laser beams to create precise, detailed patterns and distressed effects on fabric surfaces, enhancing design variety without chemical use. Compared to sandblasting, laser finishing offers environmentally safer, more consistent results with reduced health risks to workers. This technology enables rapid customization and scalability, aligning with sustainable fashion trends in denim manufacturing.

Understanding Sandblasting in Denim Manufacturing

Sandblasting in denim manufacturing involves propelling abrasive materials at high velocity to create worn and distressed effects on fabric surfaces, enhancing the garment's vintage appeal. This technique offers greater depth and texture compared to laser finishing, making it popular for achieving unique, rugged aesthetics. However, sandblasting poses significant health and environmental risks due to silica dust exposure, prompting many manufacturers to explore safer laser alternatives.

Environmental Impact: Laser Finishing vs Sandblasting

Laser finishing significantly reduces environmental impact by eliminating water waste and chemical use commonly associated with sandblasting, which relies on abrasive materials that generate toxic dust and pollutants. Sandblasting produces airborne particles harmful to both workers and surrounding ecosystems, contributing to respiratory diseases and soil contamination. The adoption of laser finishing in denim production enhances sustainability by conserving resources and minimizing hazardous emissions, aligning with industry regulations and eco-friendly standards.

Health and Safety Considerations for Workers

Laser finishing in denim production provides a safer alternative to sandblasting by significantly reducing workers' exposure to harmful silica dust, which is linked to severe respiratory diseases such as silicosis. Sandblasting generates fine particulate matter that poses serious occupational health risks, necessitating stringent protective measures that are often difficult to implement in many factories. Investing in laser technology enhances workplace safety and complies with global health standards while maintaining denim's desired aesthetic effects.

Aesthetic Outcomes: Comparing Finished Denim Looks

Laser finishing delivers precise and sharp patterns on denim, enhancing intricate details with minimal fabric damage, while sandblasting creates a more worn and natural faded effect through abrasive techniques. Laser finishing offers consistent and customizable designs ideal for premium collections, whereas sandblasting produces varied textures that evoke vintage and rugged aesthetics. The choice between these methods significantly impacts the garment's visual appeal, durability, and overall style authenticity.

Efficiency and Cost Analysis of Both Methods

Laser finishing offers higher efficiency and precision in denim production, reducing labor costs and minimizing material waste compared to sandblasting. Sandblasting requires extensive setup and longer processing times, increasing operational expenses and exposing workers to health hazards from silica dust. The upfront investment in laser technology is offset by faster turnaround and lower maintenance costs, making it a more cost-effective solution for large-scale denim manufacturing.

Innovations in Sustainable Denim Finishing

Laser finishing in denim offers precise, waterless abrasion that reduces chemical use and wastewater discharge, significantly lowering environmental impact compared to traditional sandblasting. Sandblasting involves high-pressure air and abrasive materials, often generating hazardous dust and health risks, making it less favorable amid growing sustainability standards. Innovations in sustainable denim finishing prioritize laser technology for eco-friendly production, enhancing fabric design while minimizing harmful emissions and resource consumption.

Industry Adoption Trends: Laser vs Sandblasting

Laser finishing is rapidly gaining traction in the denim industry due to its precision, sustainability, and efficiency compared to traditional sandblasting methods. Major denim brands are increasingly adopting laser technology to reduce environmental impact and enhance design customization, aligning with growing consumer demand for eco-friendly products. Despite sandblasting's historical prevalence, concerns over worker health and regulatory pressures have accelerated the shift towards laser finishing in manufacturing facilities worldwide.

Future Perspectives on Denim Finishing Technologies

Laser finishing offers a precise, eco-friendly alternative to sandblasting by reducing water usage and chemical waste in denim finishing. Emerging technologies integrate AI and automation to enhance laser precision, enabling mass customization and minimizing fabric damage. The future of denim finishing prioritizes sustainable, scalable solutions that meet consumer demands for unique textures and environmentally responsible production.

Laser finishing vs Sandblasting Infographic

materialdif.com

materialdif.com