Selvedge denim is prized for its durable, tightly woven edges that prevent fraying, crafted on traditional shuttle looms for superior quality and unique character. Non-selvedge denim is typically mass-produced on modern projectile looms, resulting in a wider fabric with raw edges that require overlocking or stitching to prevent unraveling. Choosing selvedge denim ensures premium craftsmanship and longevity, while non-selvedge denim offers affordability and versatility for everyday wear.

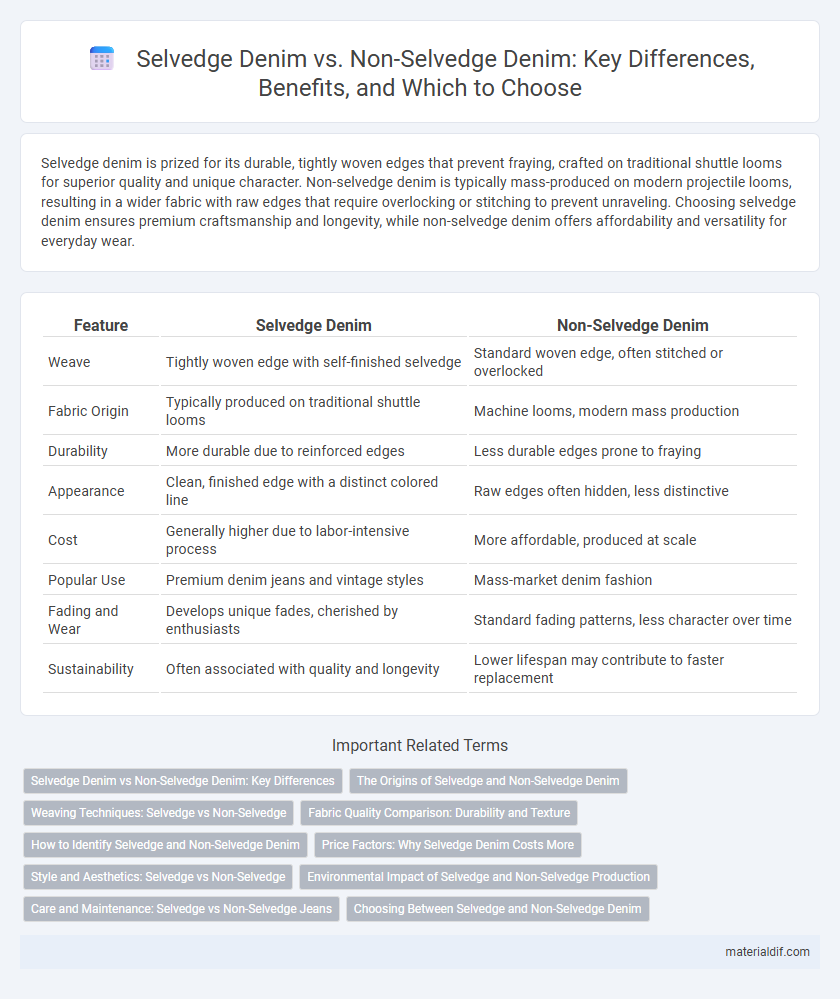

Table of Comparison

| Feature | Selvedge Denim | Non-Selvedge Denim |

|---|---|---|

| Weave | Tightly woven edge with self-finished selvedge | Standard woven edge, often stitched or overlocked |

| Fabric Origin | Typically produced on traditional shuttle looms | Machine looms, modern mass production |

| Durability | More durable due to reinforced edges | Less durable edges prone to fraying |

| Appearance | Clean, finished edge with a distinct colored line | Raw edges often hidden, less distinctive |

| Cost | Generally higher due to labor-intensive process | More affordable, produced at scale |

| Popular Use | Premium denim jeans and vintage styles | Mass-market denim fashion |

| Fading and Wear | Develops unique fades, cherished by enthusiasts | Standard fading patterns, less character over time |

| Sustainability | Often associated with quality and longevity | Lower lifespan may contribute to faster replacement |

Selvedge Denim vs Non-Selvedge Denim: Key Differences

Selvedge denim is characterized by its tightly woven self-finished edges, produced on traditional shuttle looms, resulting in higher durability and a distinctive clean edge often visible on the outseam. Non-selvedge denim is made on modern projectile looms, producing fabric with unfinished edges that require overlocking, typically leading to a less durable finish and a lower price point. The premium quality and craftsmanship of selvedge denim contribute to its higher cost and appeal among denim enthusiasts seeking longevity and unique detailing.

The Origins of Selvedge and Non-Selvedge Denim

Selvedge denim originated in the early 20th century when shuttle looms produced tightly woven fabric edges that prevented fraying, making it a hallmark of quality and durability. Non-selvedge denim emerged with the rise of modern projectile looms, allowing wider, faster production but resulting in fabric with cut edges that require overlocking or serging to prevent unraveling. The distinction between these denim types reflects differences in manufacturing techniques, fabric durability, and aesthetic appeal treasured by denim enthusiasts and artisans.

Weaving Techniques: Selvedge vs Non-Selvedge

Selvedge denim is woven on traditional shuttle looms producing tightly woven edges that prevent unraveling, characterized by clean, finished bands typically in contrasting colors. Non-selvedge denim is made on modern projectile looms, offering faster production with wider fabric widths but featuring rough, unfinished edges prone to fraying. The weaving technique of selvedge denim results in a denser, more durable fabric favored for premium jeans, while non-selvedge denim prioritizes cost-effectiveness and mass production.

Fabric Quality Comparison: Durability and Texture

Selvedge denim features tightly woven edges that prevent fraying, offering superior durability compared to non-selvedge denim, which often has loosely bound edges prone to wear and tear. The dense weave of selvedge denim creates a firmer texture and a more premium feel, while non-selvedge denim typically has a softer, less structured texture due to its mass-produced manufacturing process. High-quality selvedge denim maintains shape and develops unique fades over time, making it favored by denim enthusiasts seeking longevity and character.

How to Identify Selvedge and Non-Selvedge Denim

Selvedge denim is identified by the tightly woven edge finished with a clean, self-edge often featuring colored thread, visible when the jeans are cuffed. Non-selvedge denim lacks this distinct edge and typically has an unfinished or overlocked seam that may fray over time. Examining the inner seams of the denim fabric is the most reliable method to distinguish between selvedge and non-selvedge denim.

Price Factors: Why Selvedge Denim Costs More

Selvedge denim costs more due to its production on traditional shuttle looms, which yield higher-quality, denser fabric with clean, finished edges that reduce waste and enhance durability. The slower, more labor-intensive weaving process increases manufacturing time and expenses compared to non-selvedge denim produced on modern projectile looms. Limited availability of shuttle looms and premium raw materials also contribute to the higher price of selvedge denim garments.

Style and Aesthetics: Selvedge vs Non-Selvedge

Selvedge denim features tightly woven edges that prevent fraying, creating a clean, distinctive finish often showcased in cuffs for a premium look. Non-selvedge denim typically has a wider, less precise edge finished with overlocking stitches, offering a more casual and mass-produced aesthetic. Style enthusiasts favor selvedge denim for its authentic heritage appeal and crisp detailing, while non-selvedge denim is embraced for versatile, everyday wear.

Environmental Impact of Selvedge and Non-Selvedge Production

Selvedge denim production typically involves traditional shuttle looms that consume more energy and water, leading to higher environmental impact compared to modern projectile looms used in non-selvedge denim manufacturing. However, selvedge denim often uses higher-quality, longer-lasting cotton, potentially reducing waste over time. Non-selvedge denim processes benefit from mass production efficiencies that lower per-unit resource consumption but often rely on chemically intensive treatments that contribute to water pollution.

Care and Maintenance: Selvedge vs Non-Selvedge Jeans

Selvedge denim requires gentler care to preserve its tightly woven edge, including washing inside out in cold water and avoiding harsh detergents to maintain fabric integrity and prevent fraying. Non-selvedge denim is typically more forgiving, allowing for more frequent washes and machine drying without significant risk of edge damage. Proper maintenance of selvedge jeans prolongs their lifespan and enhances their unique fade patterns, while non-selvedge denim prioritizes convenience and durability in everyday wear.

Choosing Between Selvedge and Non-Selvedge Denim

Selvedge denim features a tightly woven edge that prevents fraying, known for superior durability and a clean finish, making it a preferred choice for premium jeans. Non-selvedge denim is typically produced on wider modern looms, resulting in a softer, more flexible fabric that is often more affordable and widely available. Choosing between selvedge and non-selvedge denim depends on the desired durability, aesthetic detail, and budget for the garment.

Selvedge denim vs Non-selvedge denim Infographic

materialdif.com

materialdif.com