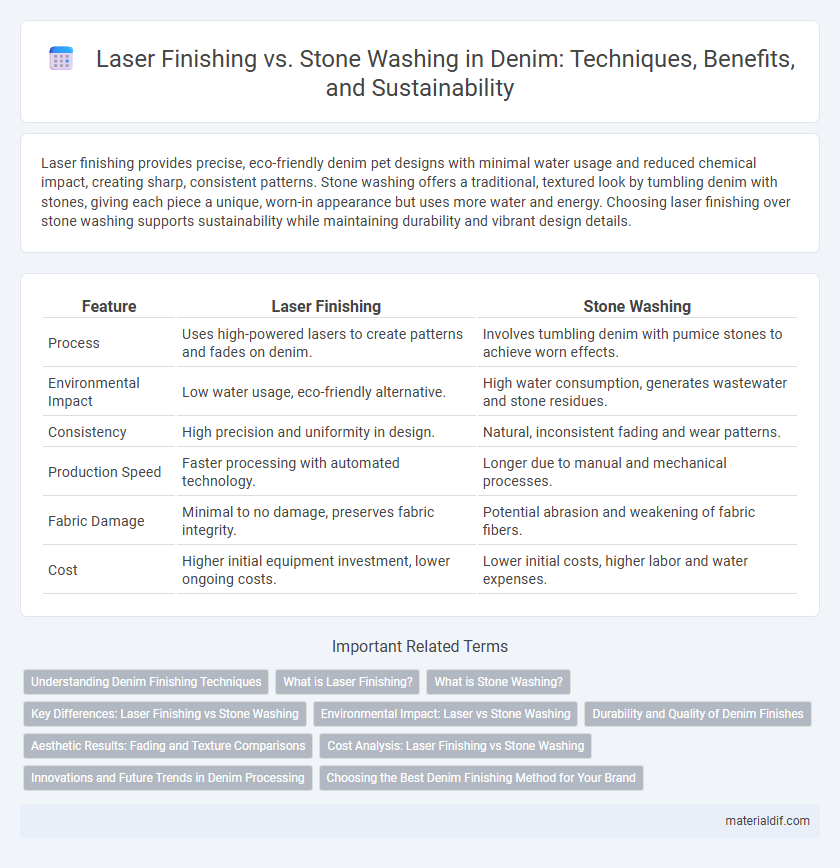

Laser finishing provides precise, eco-friendly denim pet designs with minimal water usage and reduced chemical impact, creating sharp, consistent patterns. Stone washing offers a traditional, textured look by tumbling denim with stones, giving each piece a unique, worn-in appearance but uses more water and energy. Choosing laser finishing over stone washing supports sustainability while maintaining durability and vibrant design details.

Table of Comparison

| Feature | Laser Finishing | Stone Washing |

|---|---|---|

| Process | Uses high-powered lasers to create patterns and fades on denim. | Involves tumbling denim with pumice stones to achieve worn effects. |

| Environmental Impact | Low water usage, eco-friendly alternative. | High water consumption, generates wastewater and stone residues. |

| Consistency | High precision and uniformity in design. | Natural, inconsistent fading and wear patterns. |

| Production Speed | Faster processing with automated technology. | Longer due to manual and mechanical processes. |

| Fabric Damage | Minimal to no damage, preserves fabric integrity. | Potential abrasion and weakening of fabric fibers. |

| Cost | Higher initial equipment investment, lower ongoing costs. | Lower initial costs, higher labor and water expenses. |

Understanding Denim Finishing Techniques

Laser finishing on denim offers precise, eco-friendly abrasion patterns by using high-powered laser beams to selectively burn the fabric's surface, reducing water and chemical usage compared to traditional methods. Stone washing relies on pumice stones to mechanically distress denim, creating a worn look but often causing fabric damage and significant water consumption. Understanding these techniques helps denim manufacturers balance aesthetic goals with sustainability and fabric longevity.

What is Laser Finishing?

Laser finishing is an innovative denim treatment technique that utilizes high-precision laser beams to create patterns, textures, and distress effects directly on the fabric. This method offers a sustainable alternative to traditional stone washing by significantly reducing water consumption, chemical use, and processing time. Laser finishing enhances denim aesthetics with consistent and customizable designs while minimizing environmental impact and improving production efficiency.

What is Stone Washing?

Stone washing is a denim finishing technique that involves washing jeans with pumice stones to create a worn, faded look and a softer texture. This process enhances the garment's vintage appearance by accelerating the natural aging of the fabric while preserving durability. Stone washing is widely used in the denim industry to achieve unique color variations and improve comfort without compromising the strength of the denim fibers.

Key Differences: Laser Finishing vs Stone Washing

Laser finishing offers precision and environmental benefits by using controlled laser technology to create specific patterns and fades on denim, reducing water and chemical consumption. Stone washing relies on abrasive pumice stones to naturally distress denim, resulting in unique textures but higher environmental impact due to water use and waste. The key differences lie in the environmental footprint, consistency of results, and technological complexity between laser finishing and traditional stone washing.

Environmental Impact: Laser vs Stone Washing

Laser finishing significantly reduces water consumption and chemical use compared to traditional stone washing, which relies heavily on abrasive pumice stones and large volumes of water. The laser process generates less wastewater and solid waste, lowering the overall environmental footprint of denim production. Stone washing contributes to higher energy usage and environmental pollution due to the disposal of used stones and toxic effluents, making laser finishing a more eco-friendly alternative.

Durability and Quality of Denim Finishes

Laser finishing on denim offers precise, consistent patterns with minimal fabric damage, resulting in enhanced durability compared to traditional stone washing. Stone washing involves abrasive stones that physically distress the fabric, often weakening fibers and reducing the garment's lifespan. Denim treated with laser finishing maintains higher fabric strength and color retention, delivering superior quality and longer-lasting finishes.

Aesthetic Results: Fading and Texture Comparisons

Laser finishing produces precise, consistent faded patterns with sharp contrasts and minimal fabric damage, enhancing the denim's durability and modern aesthetic appeal. Stone washing creates a softer, worn-in texture with random fading and a vintage look, resulting in a more natural, lived-in appearance but increased fabric abrasion. Both techniques influence the denim's feel and visual character, with laser finishing offering controlled design effects while stone washing delivers organic variation.

Cost Analysis: Laser Finishing vs Stone Washing

Laser finishing reduces labor and water costs significantly compared to traditional stone washing, offering a more environmentally sustainable option with lower operational expenses. Stone washing requires extensive use of pumice stones and water, leading to higher utility bills and longer production times that increase overall costs. Despite higher initial investments in laser technology, the long-term savings and increased efficiency make laser finishing a cost-effective choice in denim production.

Innovations and Future Trends in Denim Processing

Laser finishing in denim processing offers precise, environmentally friendly abrasion patterns with reduced water and chemical use compared to traditional stone washing. Innovations like AI-guided laser systems enhance customization while maintaining fabric integrity, driving sustainable production trends. Future advancements focus on integrating laser technology with digital design tools to streamline finishing processes and minimize environmental impact.

Choosing the Best Denim Finishing Method for Your Brand

Laser finishing offers precise, eco-friendly denim treatments with consistent results, reducing water consumption by up to 90% compared to traditional stone washing. Stone washing delivers a classic, worn-in look through natural abrasion but involves high water use and longer processing times. Brands prioritizing sustainability and efficiency often prefer laser finishing, while those valuing authentic texture and unique variations may opt for stone washing.

Laser Finishing vs Stone Washing Infographic

materialdif.com

materialdif.com