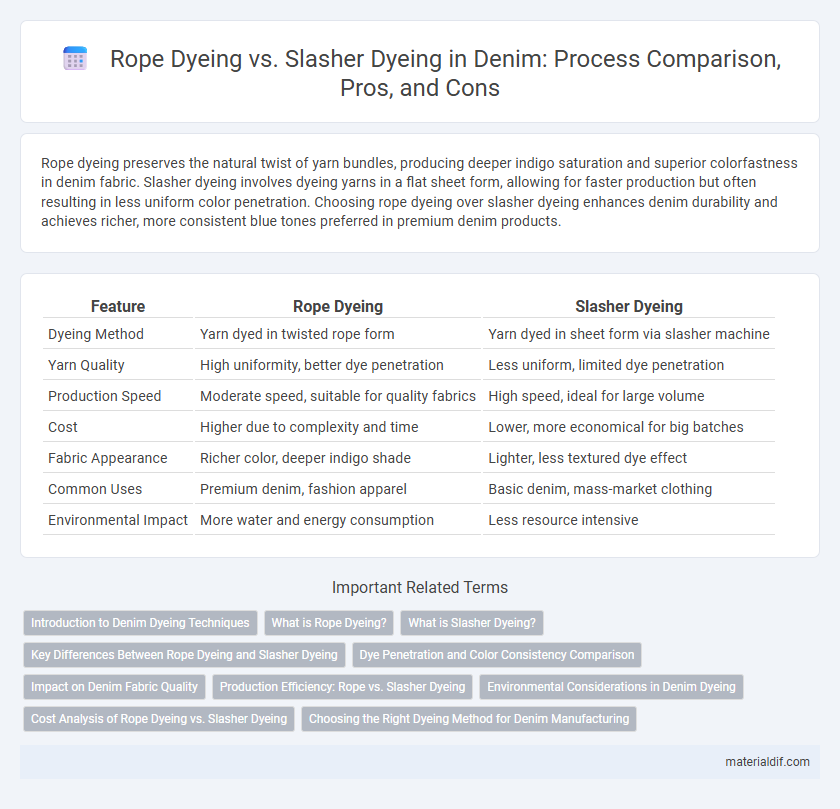

Rope dyeing preserves the natural twist of yarn bundles, producing deeper indigo saturation and superior colorfastness in denim fabric. Slasher dyeing involves dyeing yarns in a flat sheet form, allowing for faster production but often resulting in less uniform color penetration. Choosing rope dyeing over slasher dyeing enhances denim durability and achieves richer, more consistent blue tones preferred in premium denim products.

Table of Comparison

| Feature | Rope Dyeing | Slasher Dyeing |

|---|---|---|

| Dyeing Method | Yarn dyed in twisted rope form | Yarn dyed in sheet form via slasher machine |

| Yarn Quality | High uniformity, better dye penetration | Less uniform, limited dye penetration |

| Production Speed | Moderate speed, suitable for quality fabrics | High speed, ideal for large volume |

| Cost | Higher due to complexity and time | Lower, more economical for big batches |

| Fabric Appearance | Richer color, deeper indigo shade | Lighter, less textured dye effect |

| Common Uses | Premium denim, fashion apparel | Basic denim, mass-market clothing |

| Environmental Impact | More water and energy consumption | Less resource intensive |

Introduction to Denim Dyeing Techniques

Rope dyeing and slasher dyeing are two primary techniques used in denim manufacturing to achieve yarn coloration. Rope dyeing involves twisting yarns into rope form and repeatedly dipping them into indigo dye vats, resulting in deep, rich color penetration and distinctive fading characteristics. Slasher dyeing, on the other hand, passes yarns in sheet form through dye baths, offering higher production speeds but less intense dye penetration compared to rope dyeing.

What is Rope Dyeing?

Rope dyeing is a textile dyeing process where yarns are twisted into ropes and then passed through indigo dye vats, allowing deep penetration of color and enhancing denim's characteristic fading properties. This method ensures even dye distribution and maintains yarn strength, resulting in high-quality, durable denim fabric favored for premium jeans. Rope dyeing also promotes distinct fading patterns, making it essential for authentic vintage-style denim.

What is Slasher Dyeing?

Slasher dyeing is a continuous dyeing process where warp yarns are passed through a dye solution and then dried in a controlled manner, ensuring uniform color penetration and minimal shrinkage. This method enhances productivity by allowing high-speed treatment of yarns, making it ideal for large-scale denim manufacturing. The process produces consistent, vibrant indigo hues essential for quality denim fabric.

Key Differences Between Rope Dyeing and Slasher Dyeing

Rope dyeing involves twisting fibers into a rope before dyeing, producing deeper indigo penetration and superior colorfastness ideal for premium denim. Slasher dyeing applies dye directly to warp yarns on beams, allowing faster production but with less uniform dye coverage and a lighter color effect. The choice between rope and slasher dyeing impacts fabric durability, shade intensity, and overall denim quality.

Dye Penetration and Color Consistency Comparison

Rope dyeing achieves deeper dye penetration by tightly twisting yarns into ropes, allowing indigo to coat each fiber uniformly, resulting in richer color saturation and enhanced durability. In contrast, slasher dyeing involves flat yarn sheets passing through dye baths, which may lead to less uniform dye penetration and slight color inconsistencies across the fabric. Rope dyeing's superior color consistency and depth make it the preferred method for premium denim production, enhancing fabric longevity and visual appeal.

Impact on Denim Fabric Quality

Rope dyeing preserves the denim fabric's integrity by tightly twisting yarns before indigo dye penetration, resulting in deeper color depth and superior strength due to minimal fiber damage. Slasher dyeing exposes unwound yarns directly to indigo, offering higher production speeds but often compromising fabric strength and causing uneven color absorption. The choice between these methods critically affects denim durability, texture uniformity, and long-term wear resistance, with rope dyeing favored for premium denim quality.

Production Efficiency: Rope vs. Slasher Dyeing

Rope dyeing offers higher production efficiency by allowing longer fabric lengths to be dyed in a continuous process, minimizing downtime and reducing water and chemical usage. Slasher dyeing, while faster for shorter runs, involves multiple passes and less fabric tension control, which can lead to increased wastage and inconsistent color penetration. The rope dyeing method enhances fabric quality and throughput, making it the preferred technique for mass production of premium denim.

Environmental Considerations in Denim Dyeing

Rope dyeing significantly reduces water and chemical usage by dyeing yarns before fabric formation, minimizing effluent discharge compared to slasher dyeing, which involves continuous fabric dyeing with higher water consumption and wastewater generation. The rope dyeing process enhances colorfastness and fabric quality, contributing to longer garment life and less frequent replacement, indirectly reducing environmental impact. Choosing rope dyeing supports sustainable denim production by lowering energy use and chemical load, aligning with eco-friendly manufacturing goals.

Cost Analysis of Rope Dyeing vs. Slasher Dyeing

Rope dyeing incurs higher initial costs due to complex machinery and extended processing time, but it yields deeper indigo penetration and superior fabric quality, justifying the investment for premium denim brands. Slasher dyeing offers lower production costs with faster throughput, making it more suitable for mass-market denim with moderate quality requirements. Cost analysis shows rope dyeing demands greater capital and operational expenses, whereas slasher dyeing provides enhanced economic efficiency at the expense of fabric durability and color consistency.

Choosing the Right Dyeing Method for Denim Manufacturing

Rope dyeing offers superior color uniformity and depth by dyeing yarn bundles, making it ideal for high-quality denim requiring consistent indigo coverage and strength. Slasher dyeing, though faster and more cost-effective, applies dye directly to warp yarns on the loom, suitable for mass production with moderate color fastness. Selecting rope dyeing enhances durability and rich hues in premium denim, while slasher dyeing benefits large-scale manufacturing with tighter budgets.

Rope Dyeing vs Slasher Dyeing Infographic

materialdif.com

materialdif.com