Japanese denim is renowned for its meticulous craftsmanship, superior quality, and use of vintage shuttle looms, resulting in a fabric with a unique texture and durability. American denim, historically associated with rugged workwear, emphasizes heavyweight construction and bold indigo shades, offering robust performance and classic Western style. Both types excel in their premium standards but cater to distinct aesthetics and preferences within the denim pet market.

Table of Comparison

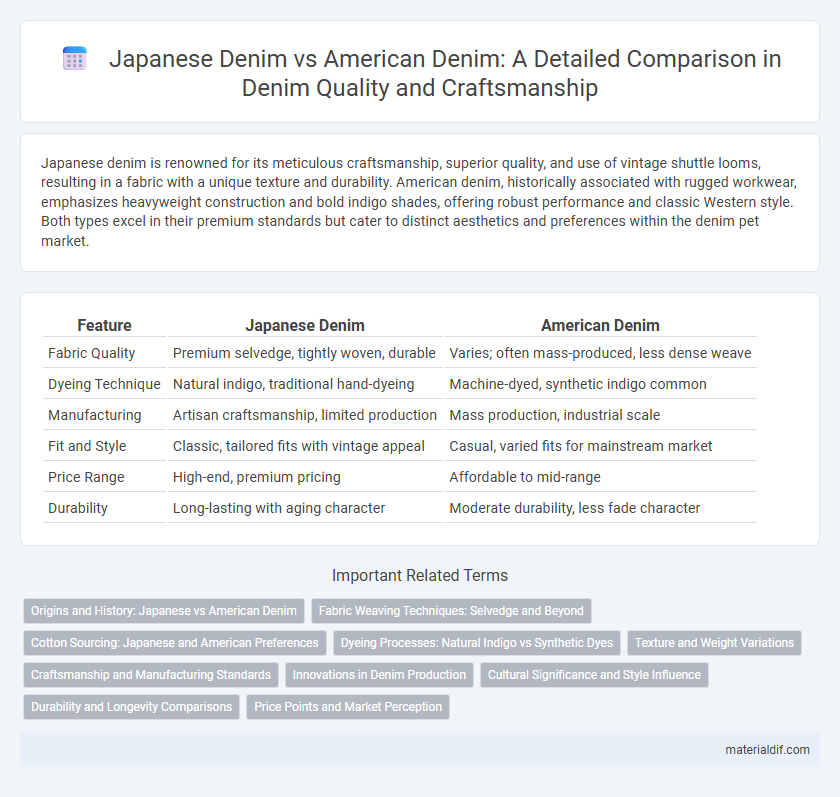

| Feature | Japanese Denim | American Denim |

|---|---|---|

| Fabric Quality | Premium selvedge, tightly woven, durable | Varies; often mass-produced, less dense weave |

| Dyeing Technique | Natural indigo, traditional hand-dyeing | Machine-dyed, synthetic indigo common |

| Manufacturing | Artisan craftsmanship, limited production | Mass production, industrial scale |

| Fit and Style | Classic, tailored fits with vintage appeal | Casual, varied fits for mainstream market |

| Price Range | High-end, premium pricing | Affordable to mid-range |

| Durability | Long-lasting with aging character | Moderate durability, less fade character |

Origins and History: Japanese vs American Denim

Japanese denim originated in the 1930s, heavily influenced by American denim but distinguished by its meticulous craftsmanship and use of vintage shuttle looms. American denim dates back to the late 1800s, rooted in the workwear tradition for miners and laborers, with brands like Levi's pioneering durable, indigo-dyed fabrics. The historical divergence reflects Japan's adaptation of denim production techniques to emphasize artisanal quality and unique texture, while American denim remains synonymous with rugged durability and mass production.

Fabric Weaving Techniques: Selvedge and Beyond

Japanese denim is renowned for its meticulous selvedge weaving technique using vintage shuttle looms, delivering a tighter, denser fabric with superior durability. American denim typically employs modern projectile looms, producing wider fabric with a softer, looser weave that caters to mass manufacturing. The selvedge edge in Japanese denim not only enhances longevity but also represents artisanal craftsmanship, setting it apart from conventional American denim production.

Cotton Sourcing: Japanese and American Preferences

Japanese denim predominantly uses high-quality cotton sourced from the United States, particularly Supima cotton, prized for its extra-long staple fibers contributing to superior softness and strength. American denim often relies on domestically grown cotton varieties, emphasizing durability and a rugged texture preferred by traditional denim manufacturers. The distinct cotton sourcing strategies influence the fabric's final texture, color absorption, and overall garment longevity, setting Japanese denim apart through refined craftsmanship and premium raw materials.

Dyeing Processes: Natural Indigo vs Synthetic Dyes

Japanese denim is renowned for its use of natural indigo dye derived from the indigofera plant, which creates deep, rich hues with a unique fading pattern over time. American denim typically employs synthetic dyes, offering consistent colorfastness and production efficiency but lacking the organic variations found in natural indigo. The traditional rope dyeing process used in Japan layers multiple dips of natural indigo, enhancing depth and durability compared to the quicker synthetic dyeing methods common in the U.S.

Texture and Weight Variations

Japanese denim is renowned for its meticulous craftsmanship, often featuring a tighter weave and a smoother, more refined texture compared to American denim, which tends to have a coarser, rugged feel. Weight variations in Japanese denim typically range from 12 to 16 ounces, offering a sturdy yet flexible fabric, while American denim encompasses a broader spectrum, including both lighter, softer weights around 10 ounces and heavier options exceeding 18 ounces. These differences in texture and weight impact durability, comfort, and aging characteristics, making Japanese denim favored for premium, detailed finishes and American denim preferred for traditional, workwear-inspired durability.

Craftsmanship and Manufacturing Standards

Japanese denim is renowned for its meticulous craftsmanship, utilizing traditional shuttle looms that produce a denser, more durable fabric with a unique texture and deep indigo color. American denim, while often more widely produced, emphasizes mass manufacturing standards focused on efficiency and consistency, frequently using modern projectile looms that result in a lighter, less textured fabric. The superior quality of Japanese denim stems from its slower production process and stringent attention to detail in every step, from fiber selection to dyeing and weaving.

Innovations in Denim Production

Japanese denim is renowned for its meticulous craftsmanship and use of vintage shuttle looms that produce tightly woven, high-quality fabric with superior durability. American denim, while rooted in traditional mass production techniques, leads in innovation through sustainable practices such as waterless dyeing and organic cotton cultivation. Both regions contribute to the advancement of denim by blending heritage techniques with modern technology to enhance fabric performance and environmental impact.

Cultural Significance and Style Influence

Japanese denim is renowned for its meticulous craftsmanship and unique selvedge edges, reflecting a deep cultural heritage rooted in traditional textile techniques. American denim, emblematic of rugged individualism and the working-class spirit, has influenced global fashion trends through its association with iconic styles like Levi's 501 jeans. Both denim styles hold significant cultural value, with Japanese denim emphasizing precision and quality, while American denim represents freedom and durability in everyday wear.

Durability and Longevity Comparisons

Japanese denim is renowned for its exceptional durability due to traditional shuttle loom weaving techniques and high-quality, long-staple cotton fibers, resulting in tight, dense fabric that withstands wear and abrasion. American denim, often produced with modern mass-production methods and ring-spun cotton, generally offers good strength but tends to be less resilient over prolonged heavy use compared to Japanese denim. The longer lifespan of Japanese denim makes it a preferred choice for consumers seeking premium denim with sustained durability and aging characteristics.

Price Points and Market Perception

Japanese denim commands a premium price due to its renowned craftsmanship, superior quality, and use of traditional shuttle looms, positioning it as a luxury product in the market. American denim, often characterized by mass production and a wider price range, is perceived as more accessible and casual, appealing to a broad consumer base seeking durability at a lower cost. The market generally associates Japanese denim with exclusivity and artisanal value, while American denim benefits from brand heritage and affordability.

Japanese denim vs American denim Infographic

materialdif.com

materialdif.com